Integrated type hydraulic retarder

A hydraulic retarder, integrated technology, applied in the direction of liquid resistance brakes, brake types, fluid pressure actuators, etc., can solve the problem of the dependence of control gas on the vehicle's air source, the influence of retarder use, and unstable air pressure, etc. problems, to achieve the effect of stability, small horizontal installation size and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in further detail below in conjunction with accompanying drawing:

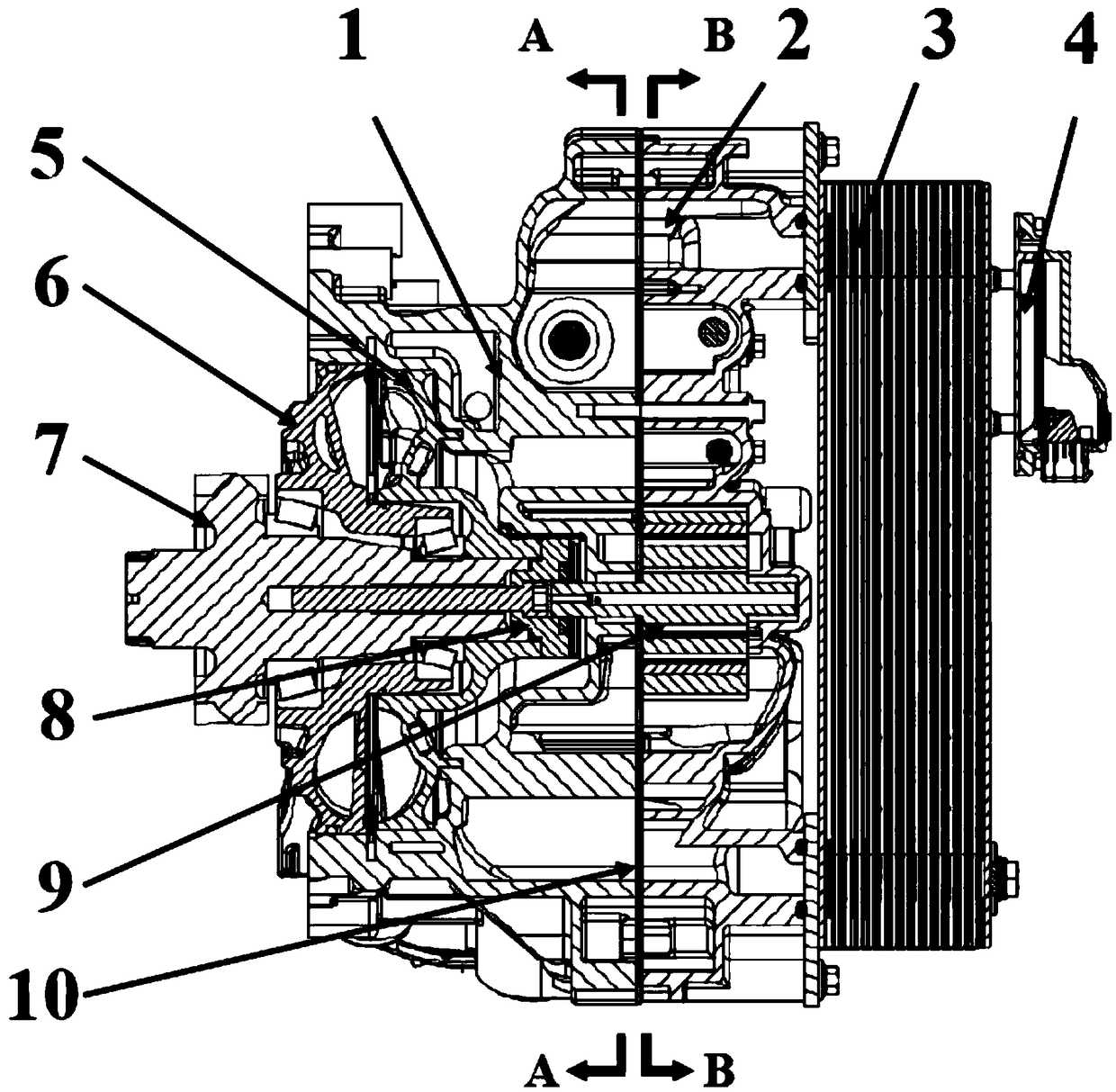

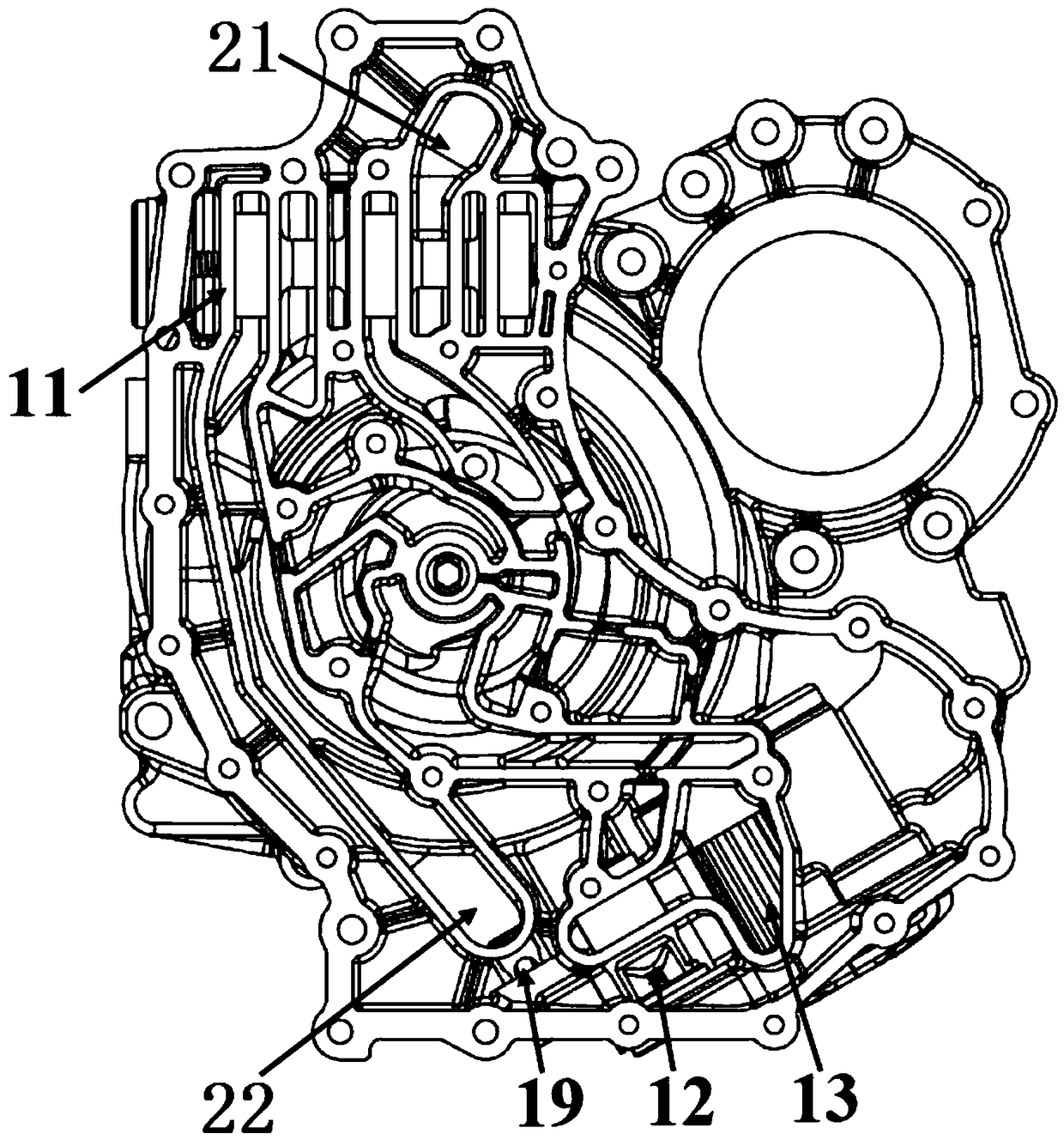

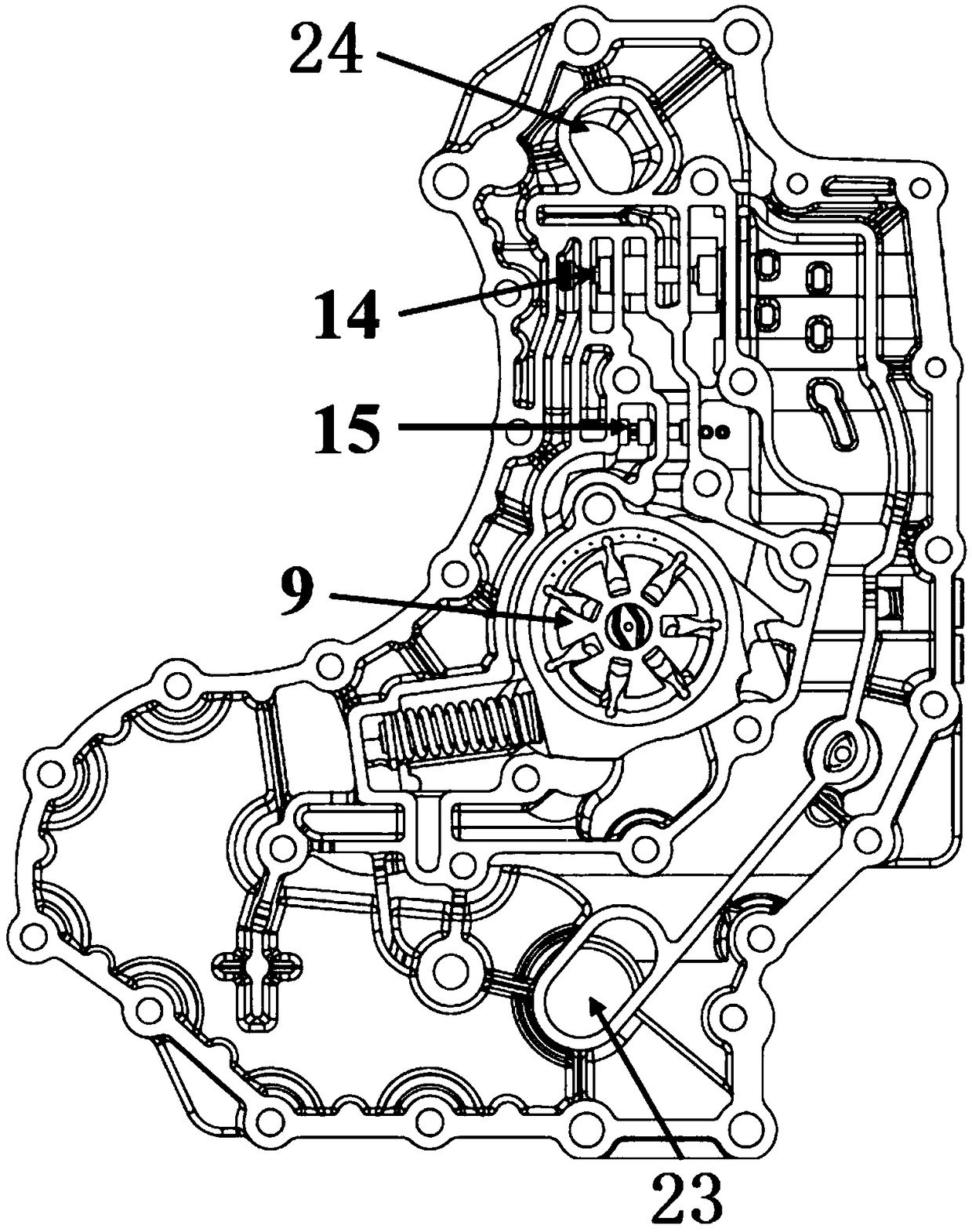

[0034] Such as Figure 1-4 As shown, the housing 1 of the integrated hydraulic retarder is connected to the rear cover of the transmission, and the internal oil pool is connected to share the working medium; the gear shaft 7 is constantly meshed with the large gear on the output shaft of the transmission sub-box to transmit the brake. torque. Inside the retarder, the gear shaft 7 is connected with the variable vane pump 9 through a flexible coupling 8 . The variable vane pump 9 is the core oil supply part of the retarder, which rotates at high speed driven by the gear shaft 7, and pumps oil from the oil pool to the working chamber of the retarder. The working chamber is the place where the stator assembly 6 and the rotor assembly 5 of the retarder work to generate torque. The stator assembly 6 is connected and fixed on the housing 1 through pins, and the rotor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com