Rotatable working platform for fully automatic assembling line

A technology of rotating worktable and assembly line, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as reducing production efficiency and increasing waiting time, and achieves the effect of improving assembly efficiency, reducing feeding time and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

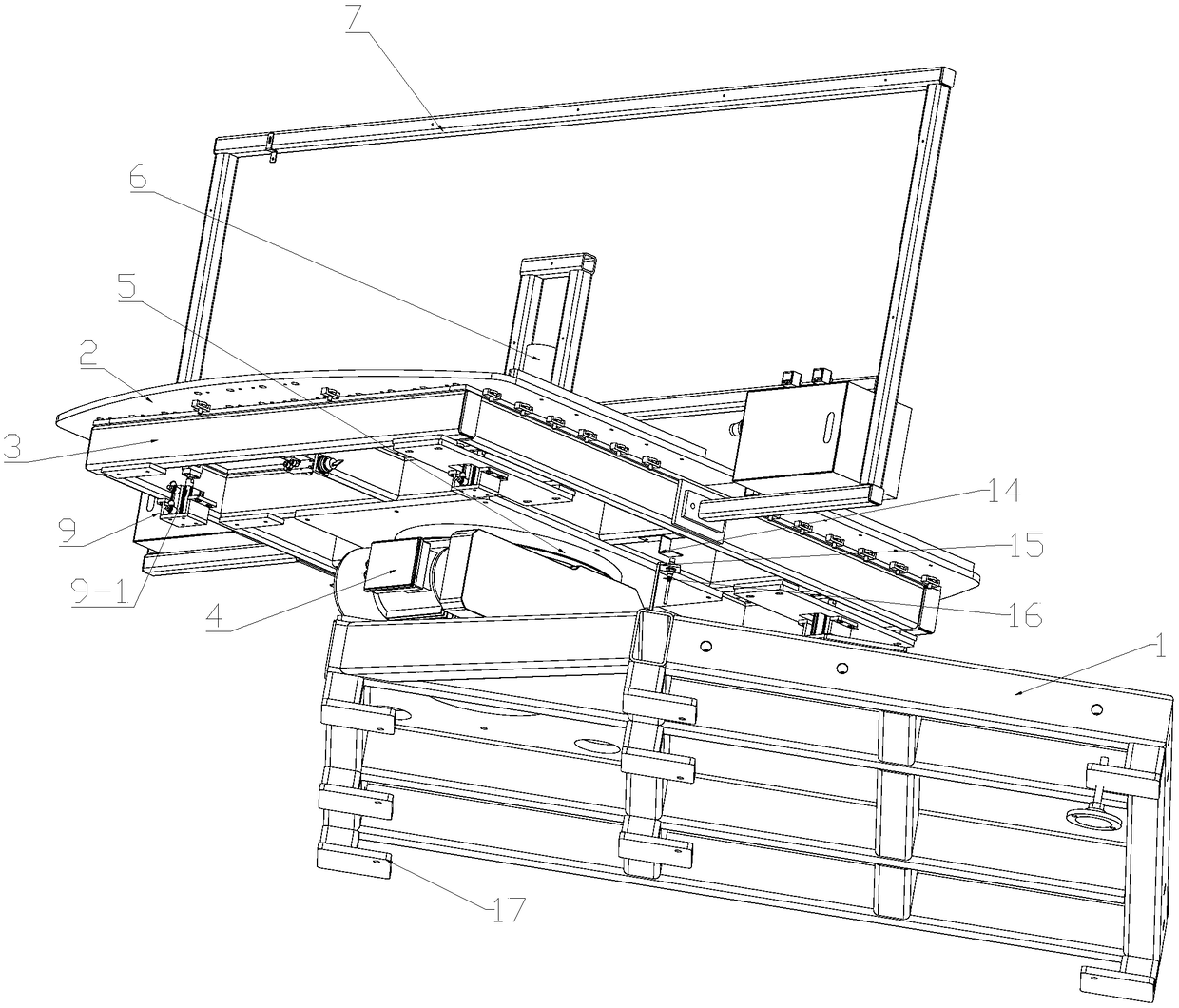

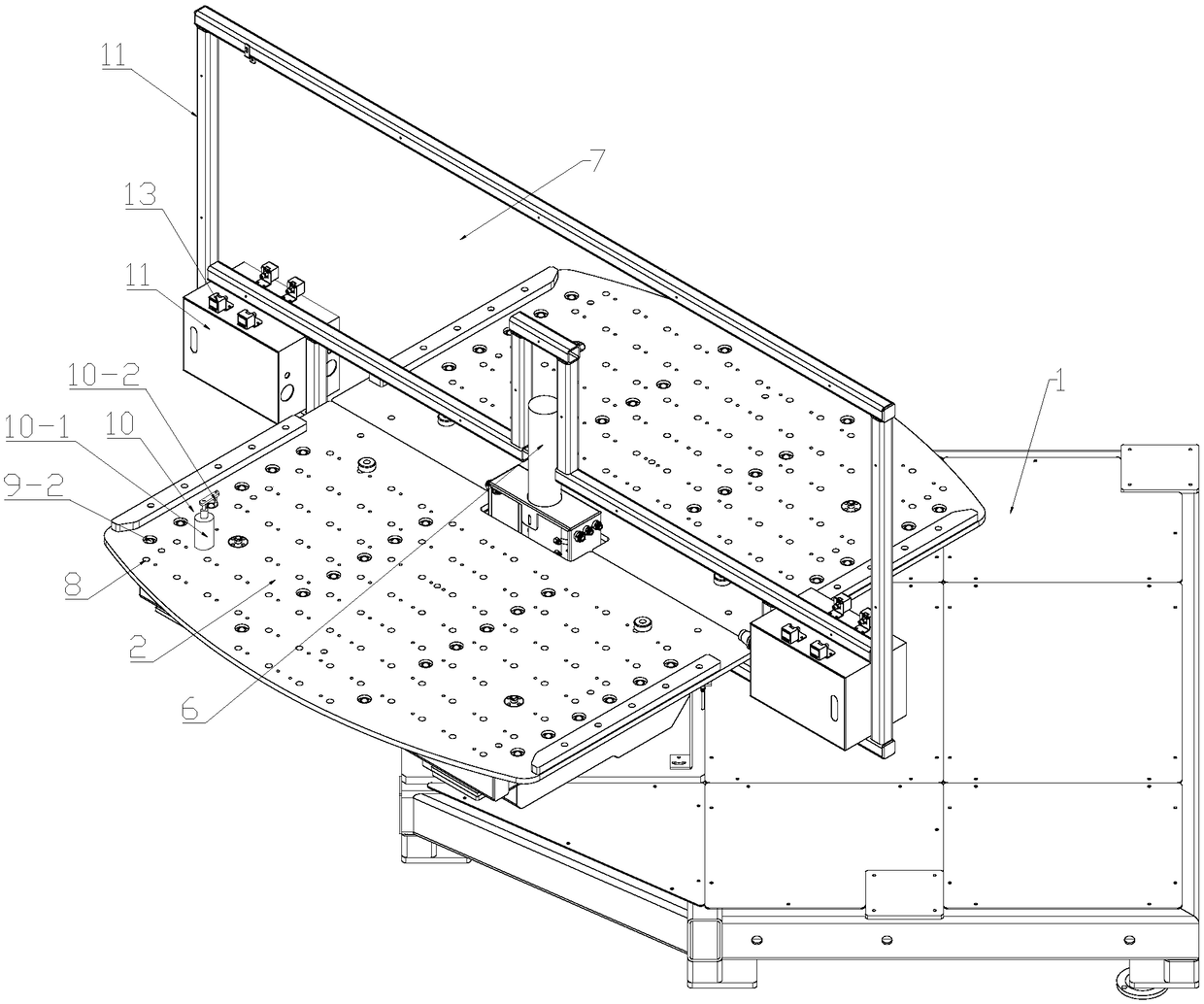

[0013] Such as Figure 1-2 As shown, a rotatable workbench for a fully automatic assembly line includes a base 1, a workbench 2, a workbench 3, and a working motor 4, wherein the base 1 is provided with a mount 5, and the mount 5 is Rotate and extend longitudinally with a rotating shaft 6, the center of gravity of the workbench 3 is sleeved with the rotating shaft 6, the working motor 4 is arranged on the mounting base 5, and the output end of the working motor 4 is linked with the rotating shaft 6, and the The workbench 3 is divided into two sides by the rotating shaft 6, and the workbench 2 is respectively laid on both sides of the workbench 3, and the workbench 3 is provided with a protective partition corresponding to the junction of the two workbenches 2. Column 7, in addition, the positioning hole 8 for positioning the workpiece to be processed is uniformly opened on the workbench 2, and the positioning pin assembly 9 is arranged on the corresponding positioning hole 8 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com