Nano-coating disperser

A nano-coating and dispersing machine technology, which is applied in the direction of mixers, mixer accessories, dissolution, etc., can solve the problems of not being able to complete the dispersing work quickly, taking a lot of time, and low dispersing efficiency, etc., to achieve simple structure and convenient feeding and discharging , Dispersing and mixing efficient and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

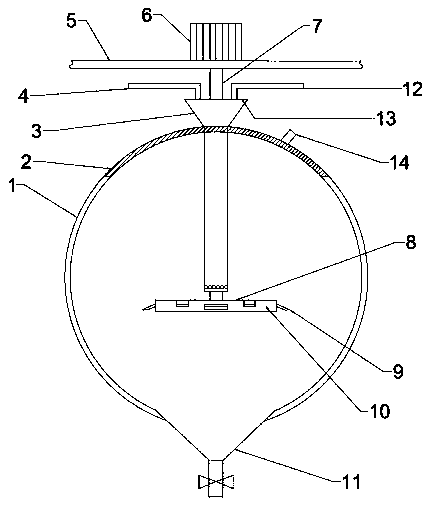

[0015] A nano-coating dispersing machine, comprising a spherical opening container 1, an arc-shaped top cover 2, a feeding device 3, a feeding pipe 4, a motor bracket 5, a motor 6, a rotating shaft 7, a stirring knife 8 and a discharge port 11 with a valve , wherein the arc-shaped top cover 2 is installed at the top opening of the spherical opening container 1, the feeding device 3 is installed in the middle of the arc-shaped top cover 2, and a pressure relief valve 14 is also installed on the arc-shaped top cover 2, and the upper part of the feeding device 3 is a funnel Located on the outside of the curved top cover 2, the lower part is a pipe and extends vertically into the inside of the spherical open container 1. The feeding pipe 4 is located above the funnel on the top of the feeding device 3. The motor bracket 5 is installed on the top of the curved top cover 2. The motor 6 is installed on the top of the curved top cover 2. On the motor support 5 and connected with the ro...

Embodiment 2

[0017] A nano-coating dispersing machine, comprising a spherical opening container 1, an arc-shaped top cover 2, a feeding device 3, a feeding pipe 4, a motor bracket 5, a motor 6, a rotating shaft 7, a stirring knife 8 and a discharge port 11 with a valve , wherein the arc-shaped top cover 2 is installed at the top opening of the spherical opening container 1, the feeding device 3 is installed in the middle of the arc-shaped top cover 2, and a pressure relief valve 14 is also installed on the arc-shaped top cover 2, and the upper part of the feeding device 3 is a funnel Located on the outside of the curved top cover 2, the lower part is a pipe and extends vertically into the inside of the spherical open container 1. The feeding pipe 4 is located above the funnel on the top of the feeding device 3. The motor bracket 5 is installed on the top of the curved top cover 2. The motor 6 is installed on the top of the curved top cover 2. On the motor support 5 and connected with the ro...

Embodiment 3

[0021] A nano-coating dispersing machine, comprising a spherical opening container 1, an arc-shaped top cover 2, a feeding device 3, a feeding pipe 4, a motor bracket 5, a motor 6, a rotating shaft 7, a stirring knife 8 and a discharge port 11 with a valve , wherein the arc-shaped top cover 2 is installed at the top opening of the spherical opening container 1, the feeding device 3 is installed in the middle of the arc-shaped top cover 2, and a pressure relief valve 14 is also installed on the arc-shaped top cover 2, and the upper part of the feeding device 3 is a funnel Located on the outside of the curved top cover 2, the lower part is a pipe and extends vertically into the inside of the spherical open container 1. The feeding pipe 4 is located above the funnel on the top of the feeding device 3. The motor bracket 5 is installed on the top of the curved top cover 2. The motor 6 is installed on the top of the curved top cover 2. On the motor support 5 and connected with the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com