Lead-acid battery

A technology of lead-acid batteries and conductive sheets, which is applied in the direction of lead-acid batteries, lead-acid battery construction, secondary batteries, etc., can solve problems such as acid stratification, improve the utilization rate, reduce the probability of battery air leakage, and extremely The effect of cluster height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

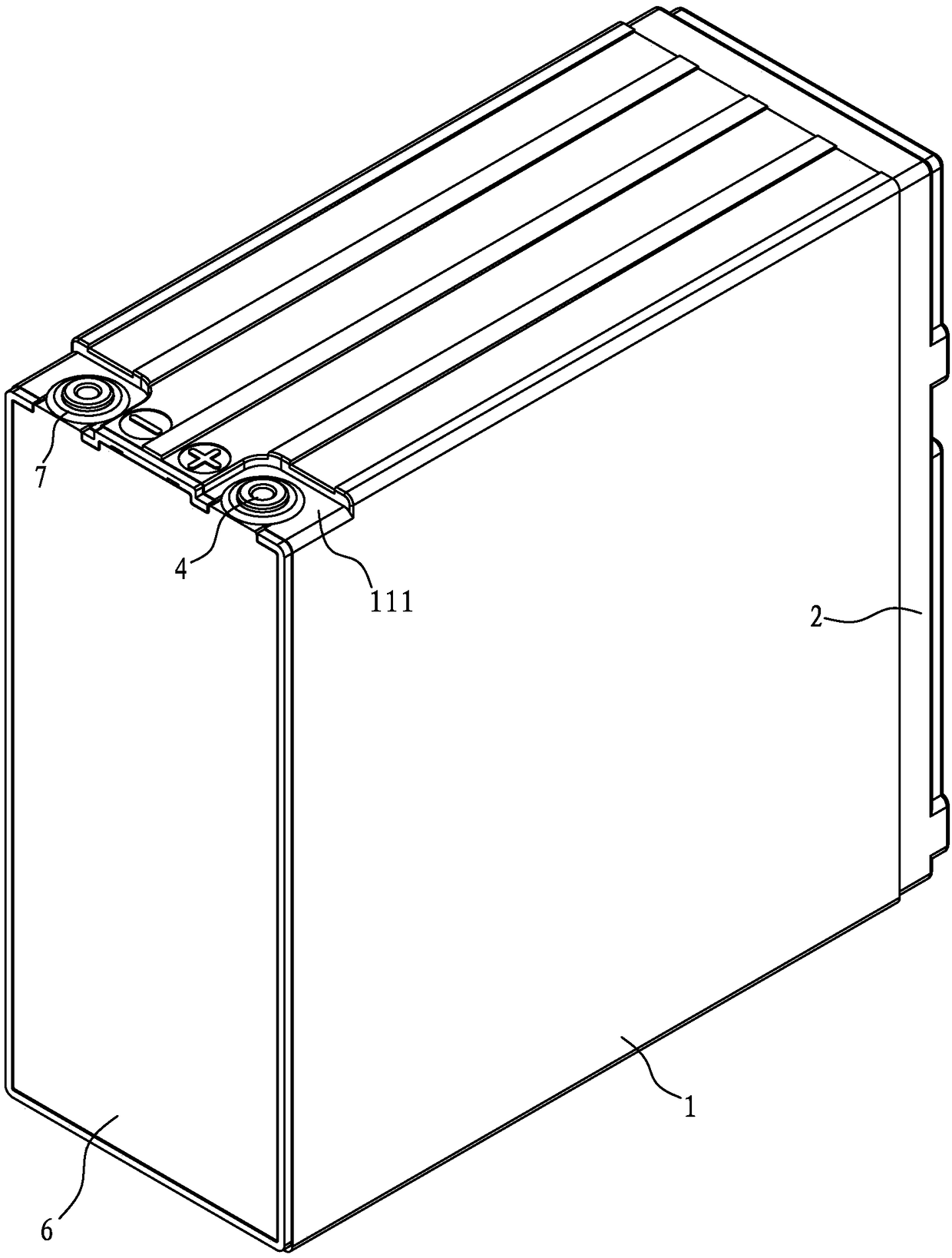

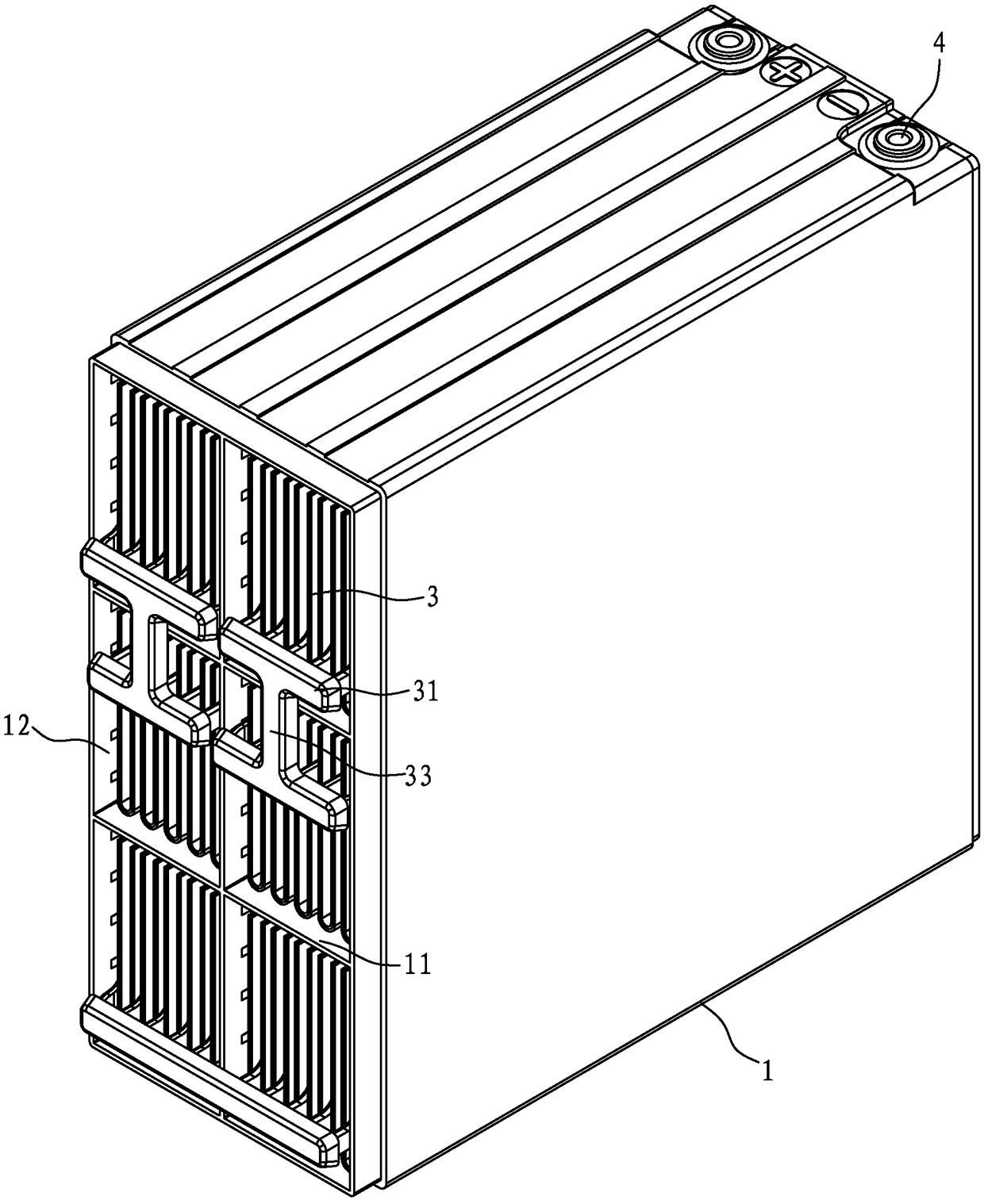

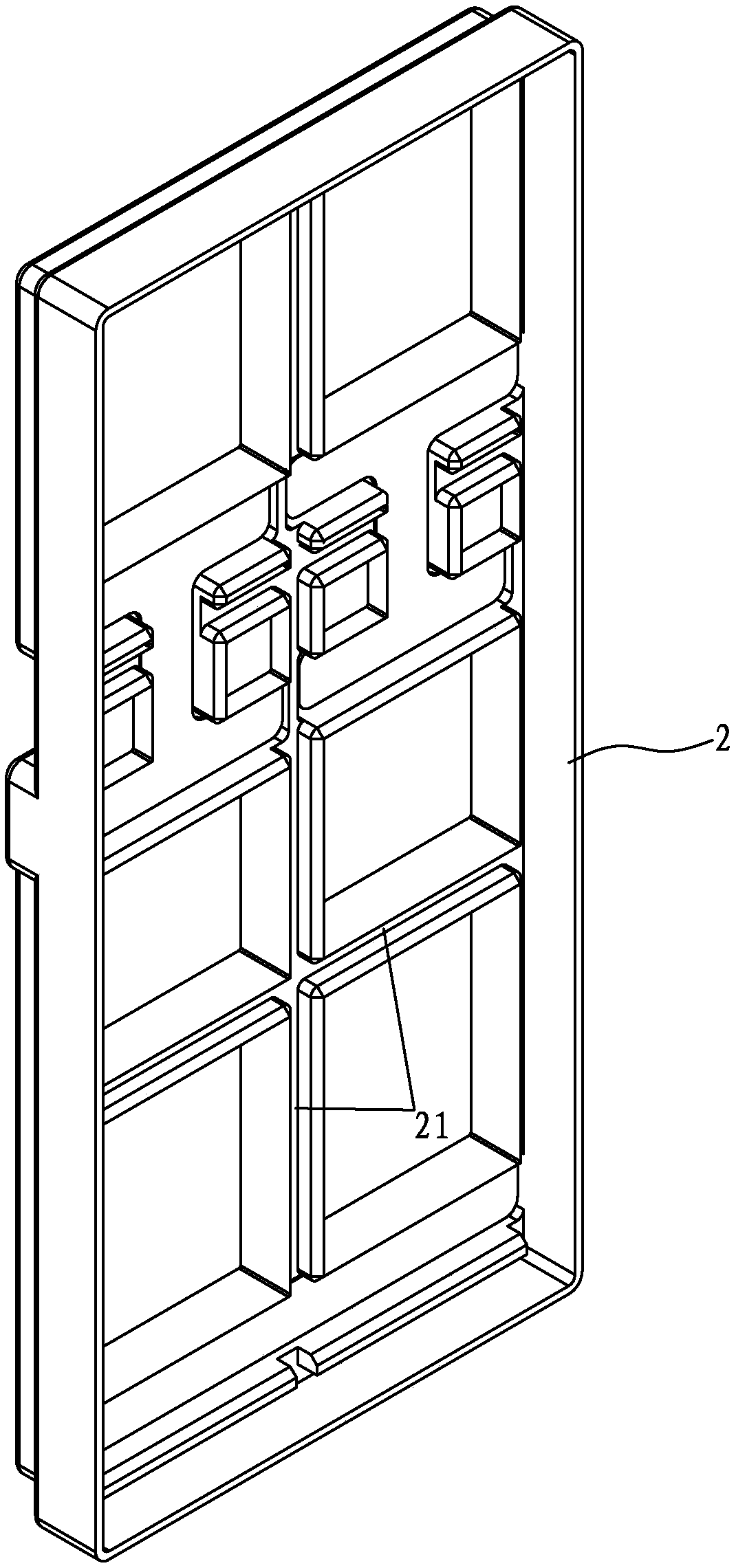

[0043] Such as Figure 1-13 As shown, a lead-acid storage battery includes: a tank body 1 with only one opening, and a partition plate 11 is arranged inside, and the partition plate 11 divides the cavity of the tank body 1 into several single cells 12, and the tank body 1 is relatively open. The bottom is provided with a liquid injection hole 13 corresponding to the single cell 12; a cover body 2 that cooperates with the tank body 1 to seal the opening; a number of pole groups 3 assembled in the tank body 1 and connected in series in sequence, each pole group 3 Bus bars (bus bar 31 and bus bar 32) with opposite polarities are arranged on both sides of the two sides, one side of the two sides is set facing the cover body 2, the other side is set back to the cover body 2, facing the cover body 2 The set bus bar 31 is connected through the bridge 33 extending into the cover body 2, and the bus bar 32 set back to the cover body 2 has poles 34 passing through the bottom of the tank...

Embodiment 2

[0052] Such as Figures 14 to 17 Shown is a schematic structural diagram of the second embodiment of the present invention, in which compared with the first embodiment of Example 1, the only difference is that the pole groups 3' are arranged in a 1×6 arrangement, and the assembly method of the terminal 4' different.

[0053] A lead-acid storage battery, comprising: a tank body 1' with only one opening, a cover body 2' cooperating with the tank body 1 to seal the opening; several pole groups 3' assembled in the tank body 1' and connected in series in sequence, each Bus bars (bus bar 31' and bus bar 32') with opposite polarities are arranged on both sides of each pole group 3', one side of the two sides is facing the cover body 2', and the other side is facing away from the cover body 2', the bus bar 31' set facing the cover 2' is directly connected by the extension of the bus bar, the bus bar 32' set back to the cover 2' has a pole 34' passing through the bottom of the groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com