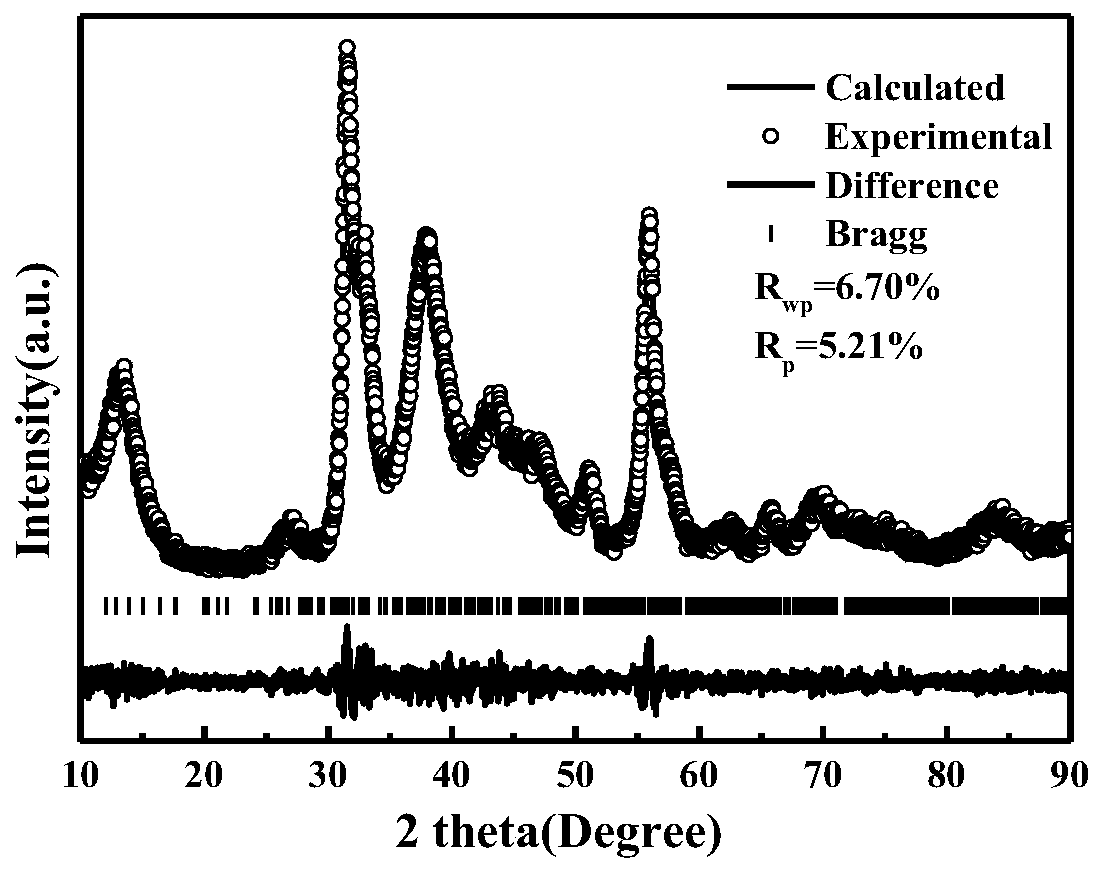

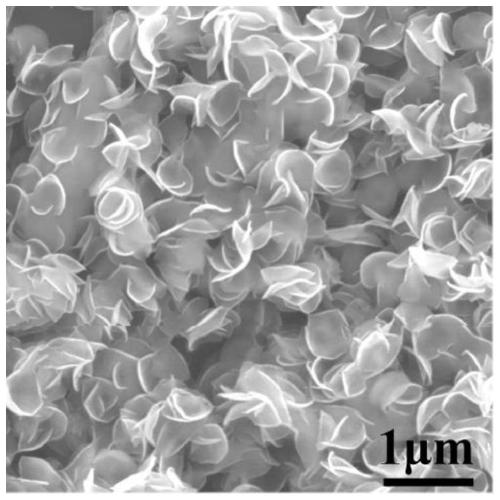

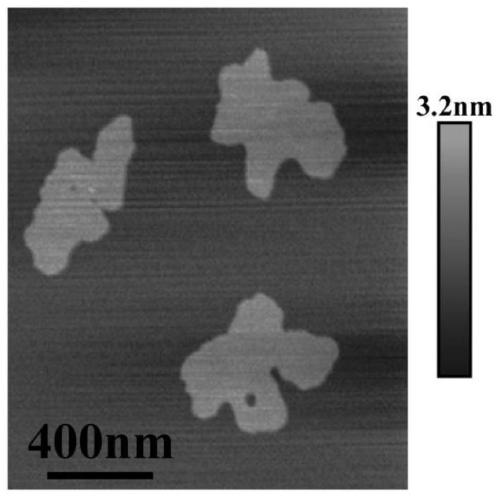

A carbon-coated ultra-thin femose 4 Preparation method of nano potato chip-like potassium ion anode material

A technology of potassium ion coating, applied in the direction of negative electrode, battery electrode, active material electrode, etc., to achieve the effects of inhibiting volume expansion, enhancing electrical conductivity, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Add 0.1mmol ferric chloride hexahydrate and 0.1mmol molybdic acid into a single-necked flask filled with 10mL oleylamine and 2mL oleic acid, place it in a heating mantle, heat to 90°C at a heating rate of 5°C / min, and keep it warm for 30min. Then cool the orange solution to room temperature, add 0.2mmol selenium powder to the single-necked flask, heat it to 180°C for 20 minutes and keep it warm for 30 minutes, the obtained black solution is naturally cooled to room temperature and collected by centrifugation, washed at least 5 times with cyclohexane and dried in a vacuum oven at 80 °C for 12 h. Then the dried powder was transferred to a crucible, and the crucible was placed in a tube furnace and heated to 600 °C at a heating rate of 5 °C / min in N2 atmosphere, and kept for 2 hours. After the tube furnace cooled, the black product was collected to obtain Nitrogen-doped carbon-coated ultrathin FeMoSe 4 The nano potato flake potassium ion negative electrode composite materi...

Embodiment 2

[0036] Add 0.1mmol ferric chloride hexahydrate and 0.1mmol molybdic acid into a single-necked flask filled with 10mL oleylamine and 2mL oleic acid, place it in a heating mantle, heat to 90°C at a heating rate of 5°C / min, and keep it warm for 30min. Then cool the orange solution to room temperature, add 0.2 mmol of selenium powder to the single-necked flask, heat it to 180°C for 20 minutes and keep it warm for 60 minutes, the obtained black solution naturally cools down to room temperature and is collected by centrifugation, washed at least 5 times with cyclohexane and dried in a vacuum oven at 80 °C for 12 h. Then the dried powder was transferred to a crucible, and the crucible was placed in a tube furnace and heated to 600 °C at a heating rate of 5 °C / min in N2 atmosphere, and kept for 2 hours. After the tube furnace cooled, the black product was collected to obtain Nitrogen-doped carbon-coated ultrathin FeMoSe 4 Nano potato flake potassium ion negative electrode composite m...

Embodiment 3

[0038] Add 0.1mmol ferric chloride hexahydrate and 0.1mmol molybdic acid into a single-necked flask filled with 10mL oleylamine and 2mL oleic acid, place it in a heating mantle, heat to 90°C at a heating rate of 5°C / min, and keep it warm for 30min. Then the orange solution was cooled to room temperature, 0.2 mmol of selenium powder was added to the single-necked flask, heated to 180°C for 20 minutes and kept for 2 hours, the obtained black solution was naturally cooled to room temperature and collected by centrifugation, washed at least 5 times with cyclohexane and dried in a vacuum oven at 80 °C for 12 h. Then the dried powder was transferred to a crucible, and the crucible was placed in a tube furnace and heated to 600 °C at a heating rate of 5 °C / min in N2 atmosphere, and kept for 2 hours. After the tube furnace cooled, the black product was collected to obtain Nitrogen-doped carbon-coated ultrathin FeMoSe 4 The nano potato flake potassium ion negative electrode composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com