A suction disk-type electromagnet sealing magnetic conductivity structure

An electromagnet and sucker-type technology, which is applied in the field of deep-sea exploration, can solve problems such as different electromagnet forms, and achieve the effects of short delivery cycle, easy replacement, and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail.

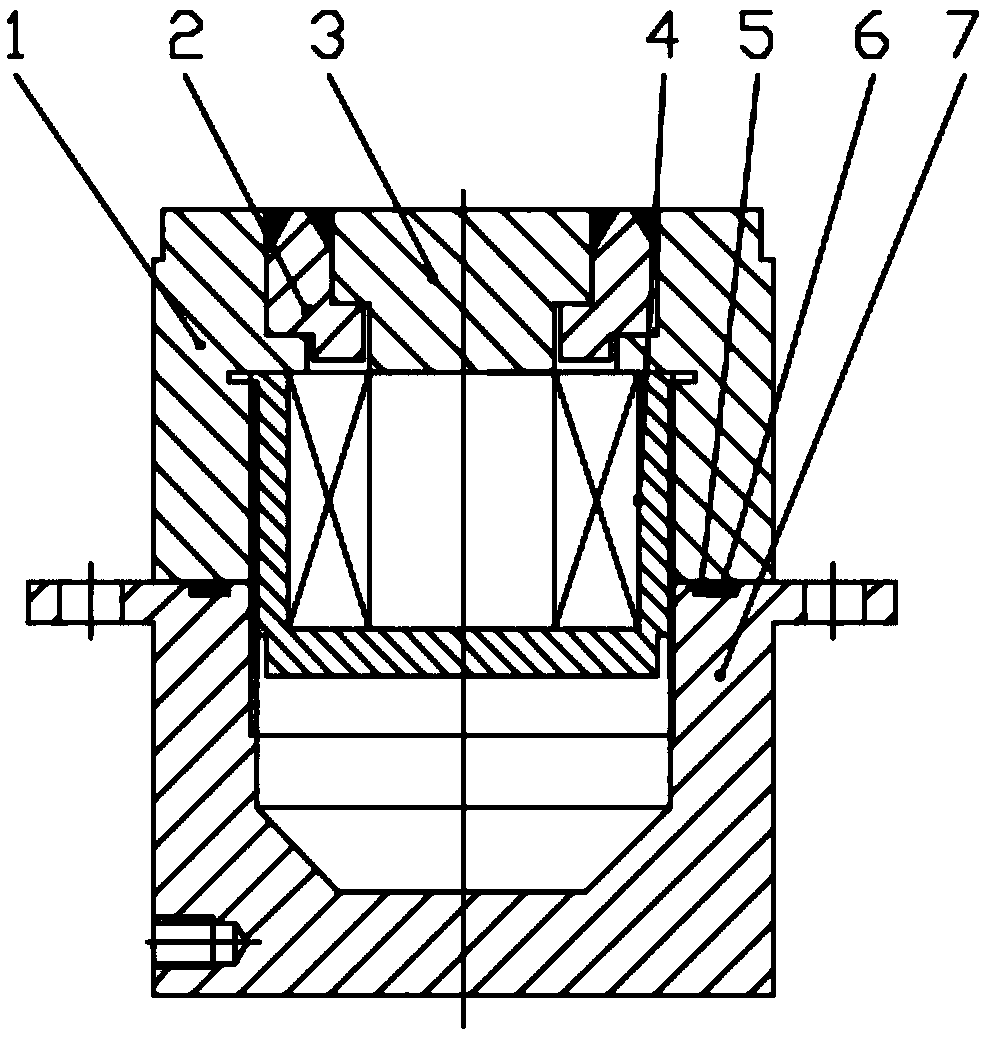

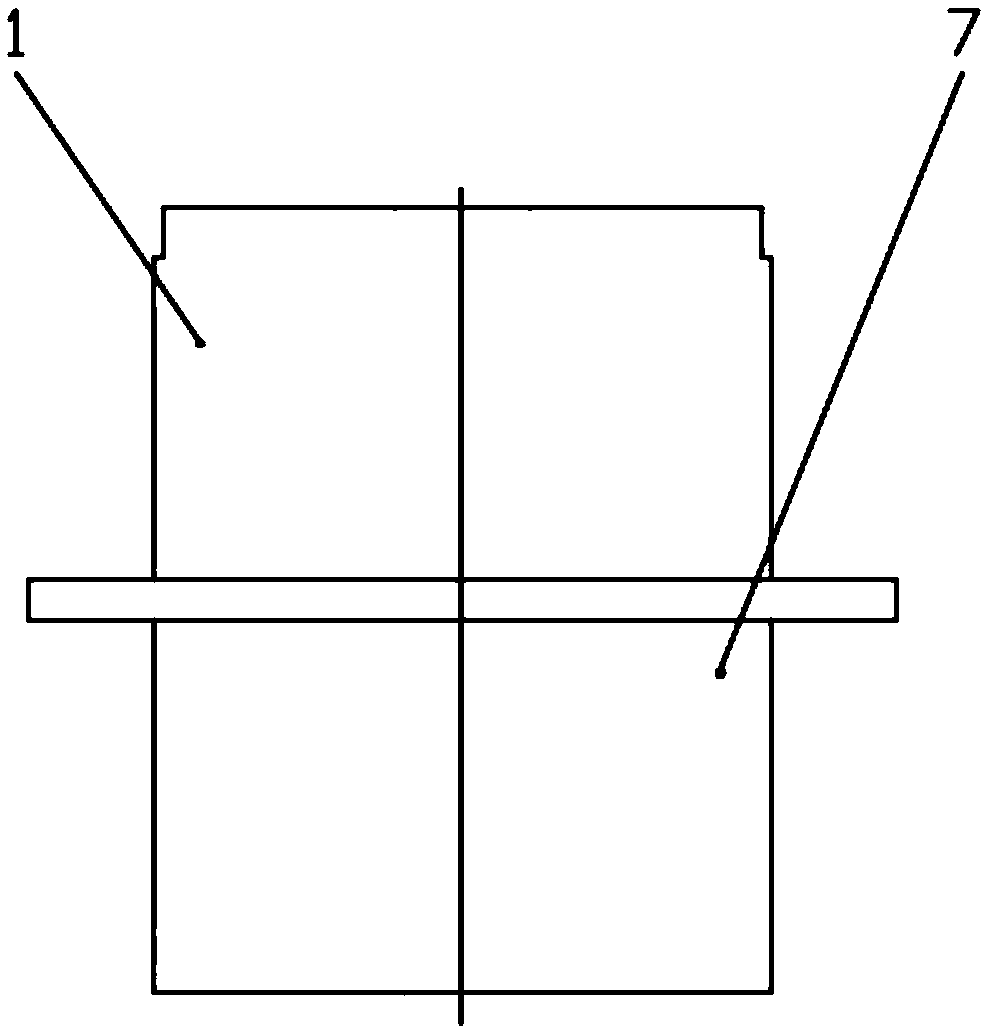

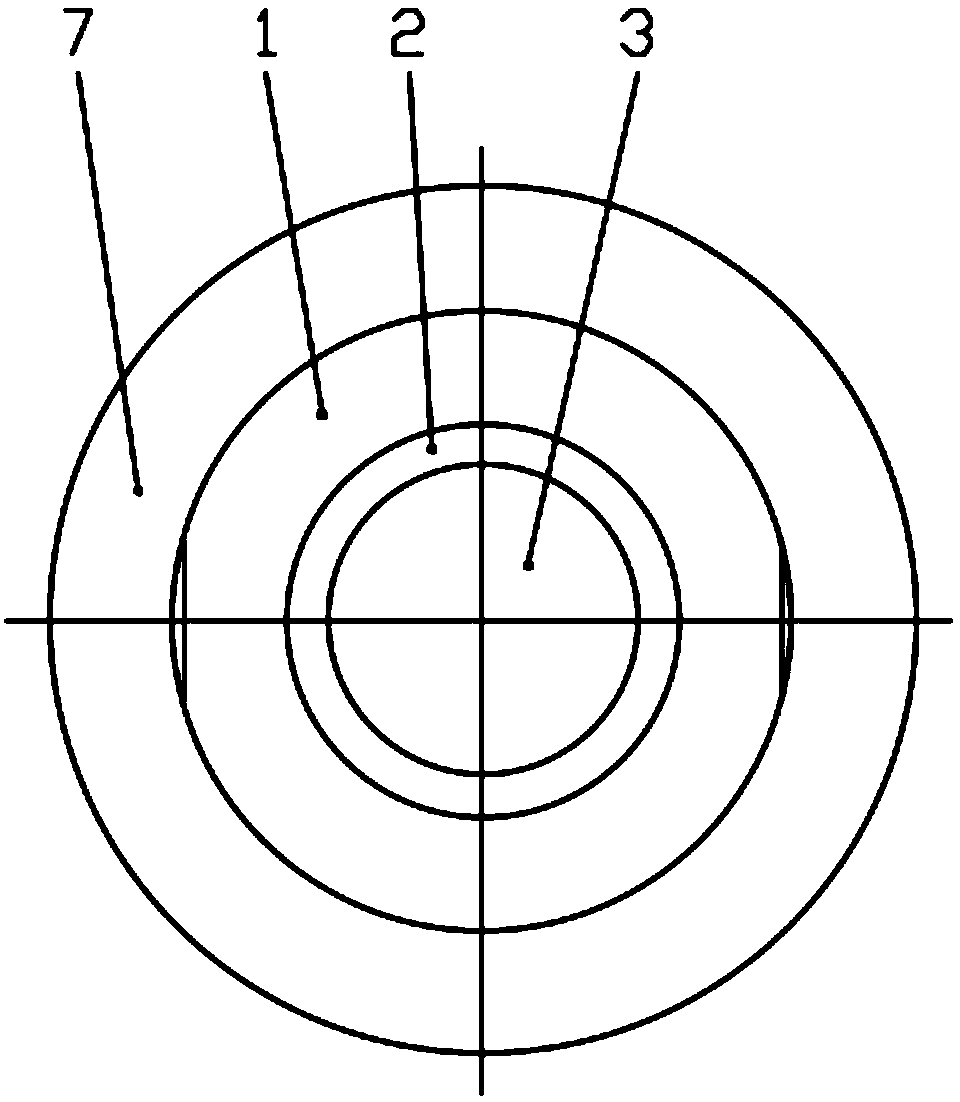

[0018] The patent of the present invention relates to a sucker-type electromagnet sealed magnetic conduction structure, which is mainly composed of four parts: an upper cover 1, a magnetic conduction cylinder 3, a pressure bearing part 2, and a lower cover 7. The magnetically conductive cylinder 3 and the upper cover 1 are made of magnetically conductive material, the pressure bearing part 2 and the lower cover 7 are made of nonmagnetically conductive material; one end of the magnetically conductive cylinder 3 is in close contact with the magnetic core of the electromagnet 4, and the upper cover 1 is in contact with the shell of the electromagnet 4 , When the electromagnet 4 is in the working state, the attracted object forms a closed magnetic circuit with the upper cover 1, the shell of the electromagnet 4, the magnetic core and the magnetic conduction c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com