Building plate material surface smoothness detection device

A technology for surface flatness and building boards, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of inconvenient board flatness, drawing boards placed together, etc., to achieve intuitive detection results, high detection accuracy, and operability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

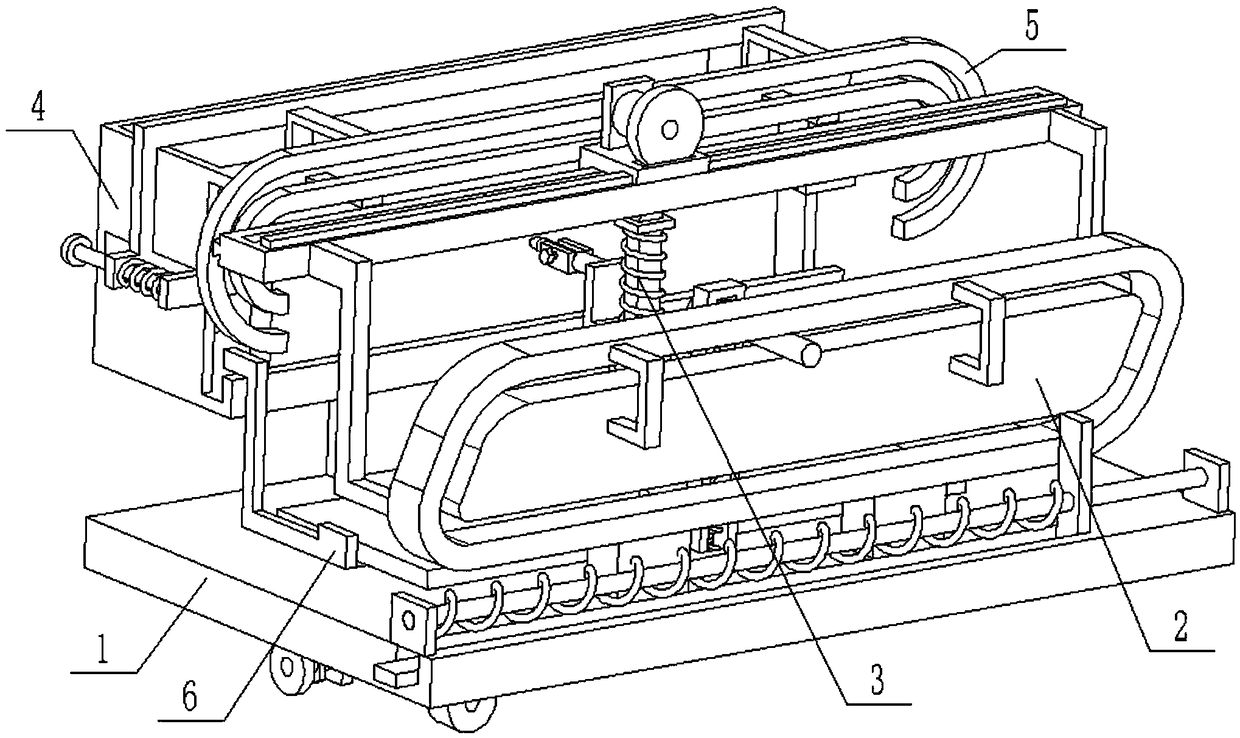

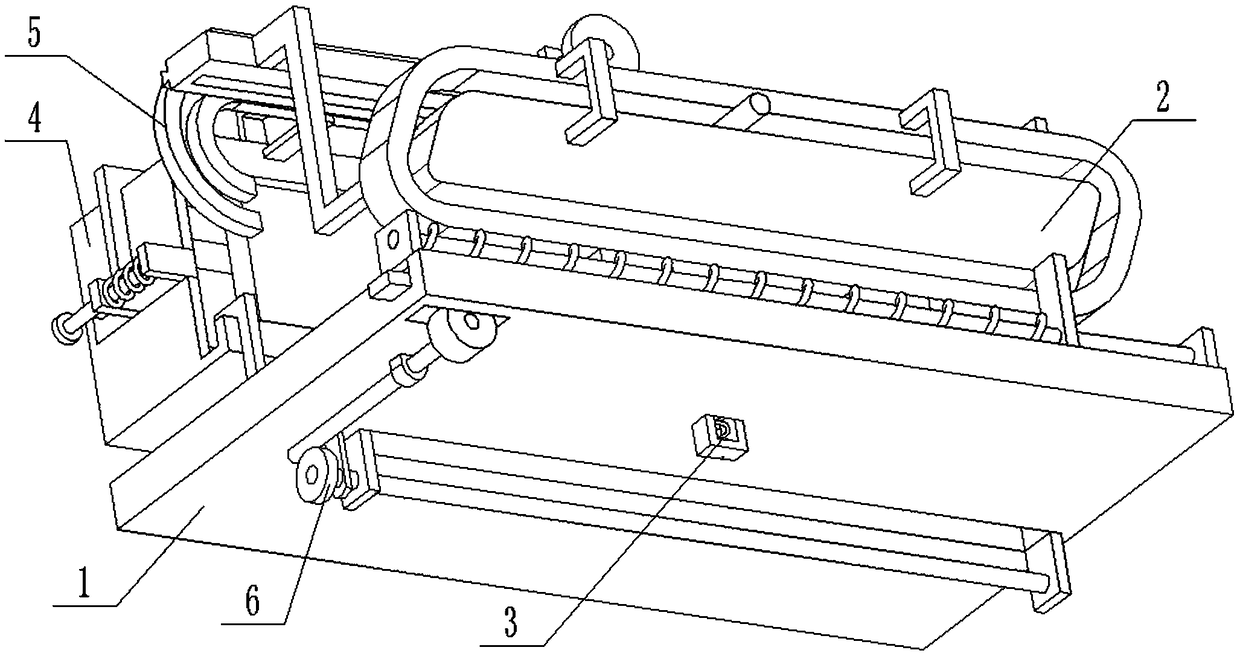

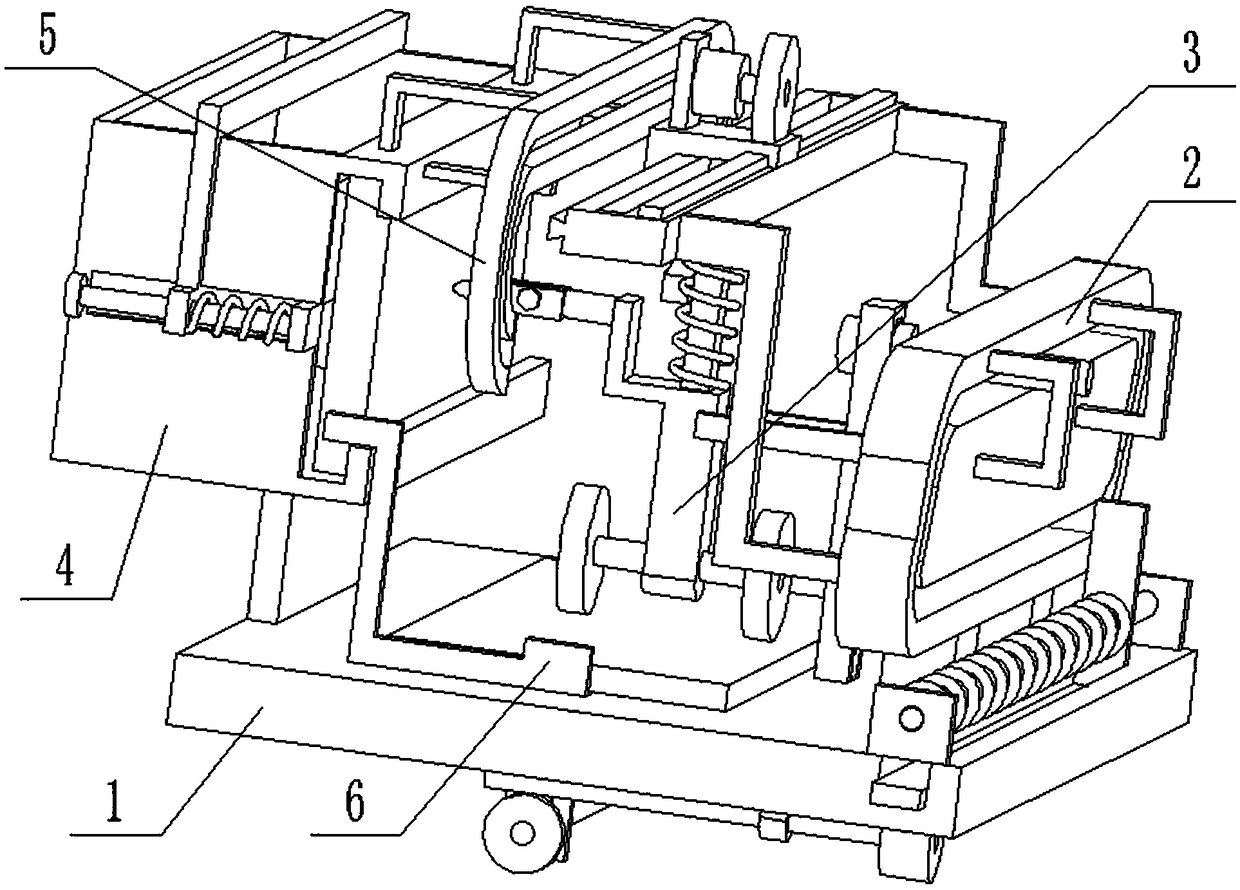

[0038] Combine below Figure 1-13 Describe this embodiment, a device for detecting the surface roughness of building boards, including a detection platform 1, a slide rail 2, a reciprocating slide seat 3, a drawing board storage seat 4, a guide rail 5, and a reciprocating dial 6. The detection platform 1 is There are dial chute 1-1, through groove 1-2, rack groove 1-3 and gear groove 1-4; Located between the dial chute 1-1 and the rack groove 1-3, the gear groove 1-4 communicates with the rack groove 1-3;

[0039] The slide rail 2 includes a support seat 2-1, a chute frame 2-2, a U-shaped seat 2-3, a center plate 2-4, a folding rod 2-5, a horizontal sliding frame 2-6, and a rack I 2- 7. The trapezoidal convex strip 2-8 and the closed chute 2-9; the chute frame 2-2 is fixedly connected to the detection platform 1 through two support seats 2-1, and the center plate 2-4 passes through two U-shaped seats 2 -3 is fixedly connected to the center of the chute frame 2-2, a closed ch...

specific Embodiment approach 2

[0044] Combine below Figure 1-13 To illustrate this embodiment, the reciprocating slide 3 also includes a motor 3-5 and a drive wheel 3-6; the lower end of the drive wheel 3-6 passes through the slot 3-4 and is engaged with the rack I 2-7 to drive Wheel 3-6 is fixedly connected on the output shaft of motor 3-5, and motor 3-5 is fixedly connected on the L-shaped sliding seat 3-1 by motor seat. The motor 3-5 is a forward and reverse motor. Connect the motor 3-5 to the power supply and the control switch through the wire and turn it on. The motor 3-5 drives the driving wheel 3-6 to rotate, and the driving wheel 3-6 meshes with the rack Ⅰ 2-7 Drive the L-shaped sliding seat 3-1 to move left and right on the horizontal sliding frame 2-6.

specific Embodiment approach 3

[0045] Combine below Figure 1-13 To illustrate this embodiment, the drawing board receiving seat 4 also includes a first convex plate 4-4, a second convex plate 4-5, a spring sleeve rod 4-6, an extrusion plate chute 4-7, an extrusion plate 4-8, tension spring 4-9, door-shaped plate 4-10 and support plate 4-11; the storage seat body 4-1 is fixedly connected to the detection platform 1 through the support plate 4-11, and the storage seat body 4-1 The two ends of 1 are respectively fixedly connected with a first convex plate 4-4 and a second convex plate 4-5, and the first convex plate 4-4 and the second convex plate 4-5 are fixedly connected with a spring sleeve rod 4-6 Both ends of the storage seat body 4-1 are provided with an extrusion plate chute 4-7 communicating with the interior of the storage seat body 4-1, and the extrusion plate 4-8 is slidably connected to the interior of the storage seat body 4-1. The two ends of the extruding plate 4-8 are respectively slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com