Rose drying and bud water synchronous recycling method

A rose and drying technology, applied in separation method, drying gas arrangement, local stirring dryer, etc., can solve the problems of high technical cost, low product quality, and high labor cost, and achieve the goal of improving drying speed, saving resources, and reducing energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

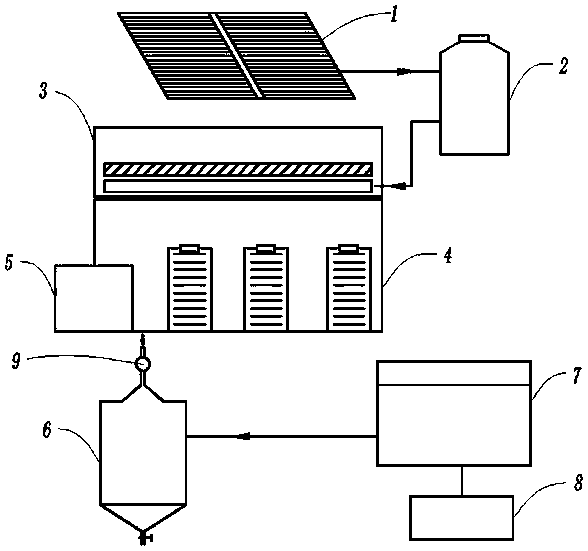

[0036] Embodiment 1: as shown in the figure, a kind of method that rose drying and flower bud water recover synchronously, comprises the following steps:

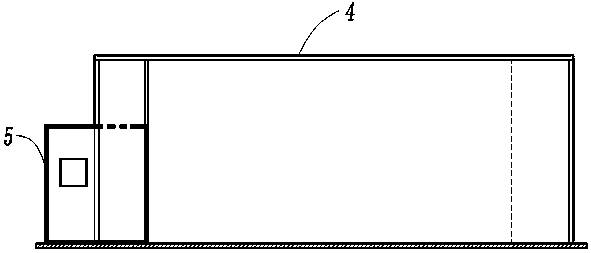

[0037] a, above the drying room 4, add a self-made solar thermal collector, and the solar thermal collector includes a solar thermal collector 1, a hot water tank 2 and a solar greenhouse 3, and the solar greenhouse 3 is provided with a metal thermal collector plate 13 and cooling fins 14, the solar heat accumulator 1, the hot water tank 2 and the cooling fins 14 are sequentially connected through pipelines, and the material tray frame 11 in the drying room 4 is equipped with a high-frequency micro-vibration eccentric machine 10, The power of the high-frequency micro-vibration eccentric machine 10 is 200W, and the frequency is 1000-1400Hz;

[0038] b. Use the air energy heat pump dryer 5 to heat the air in the drying room to a temperature of 53-58°C;

[0039] c. Place the roses on the material tray 11, turn on the high-fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com