Foil end face gas film sealing structure with enhanced radial flow-induced opening

A technology of air film sealing and radial flow, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc. It can solve the problems of poor opening performance of air film sealing on the foil end face, improve opening performance and reduce airflow resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

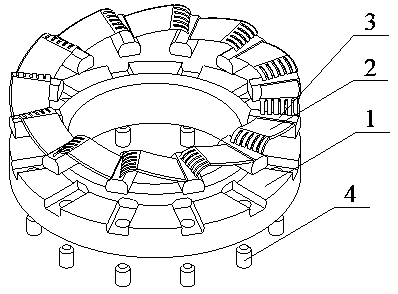

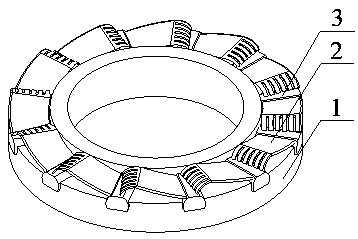

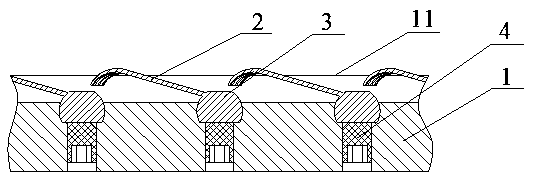

[0026] refer to Figure 1-Figure 8 As shown, the present invention is a foil end surface gas film sealing structure with enhanced radial flow-induced opening, including a gas film-sealed moving ring and a static ring; it is characterized in that:

[0027] At least one sealing ring in the moving ring or static ring is a floating ring supported by a spring, the sealing end face of the floating ring is a foil end face, one side of the foil end face is the high pressure side, and the foil end face The other side is the low pressure side;

[0028] The end surface of the foil includes a ring-shaped ring body 1, foil 2, foil fixing seat 3, and set screw 4; the outer side of the ring body 1 is lowered to form a circular concave surface, and the inner side of the ring body is raised, An annular step is formed, the upper surface of the annular step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com