A Gas Linear Damping Constant Stiffness Vibration Isolator

A damping, constant stiffness technology, applied in gas shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of constant stiffness and increased damping that are difficult to meet electronic equipment, and achieve simple and reasonable structure and constant stiffness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

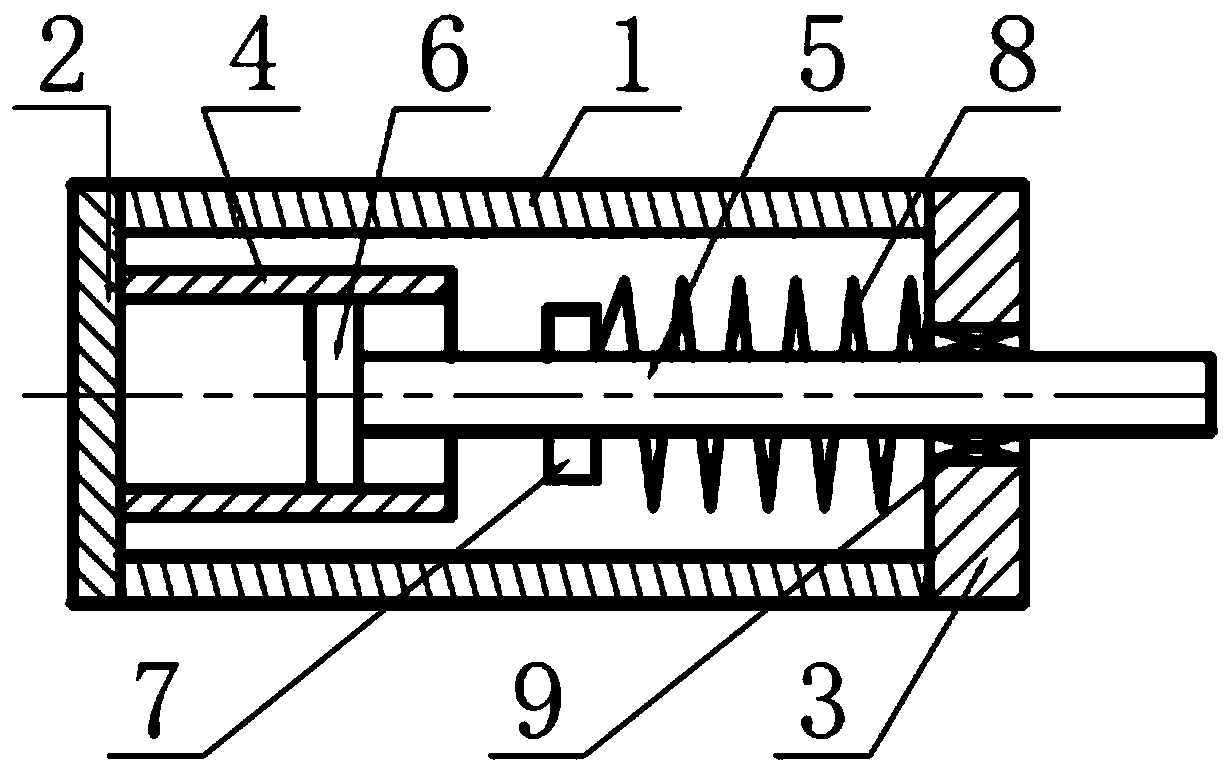

[0013] see figure 1 As shown, a gas linear damping constant stiffness vibration isolator of the present invention includes a housing 1, end caps A2 and B3 installed at both ends of the housing 1, and a composite piston module installed inside the housing.

[0014] see figure 1 As shown, the composite piston module includes a cylinder body 4 , a freely slidable piston 6 mounted inside the cylinder body 4 , a piston rod 5 mounted on the piston 6 , and a baffle 7 mounted on the piston rod 5 .

[0015] see figure 1 As shown, the other end of the piston rod 5 extends to the outside of the end cover B3 through the linear bearing 9 installed on the end cover B3; Metal coil spring 8. Further, the metal coil spring 8 is an ordinary spring whose load-displacement curve has a softening characteristic.

[0016] see figure 1 As shown, the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com