Combined type steel rope net system

A steel cable net and combined technology, which is applied in the field of steel cable net system, can solve the problems that affect the service life of the node lock installation node lock, the difficulty in realizing the interconnection of steel wire ropes, and the fixed angle, so as to reduce the wear and tear of the membrane material The effect of reducing the risk, reducing the amount of on-site installation, and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

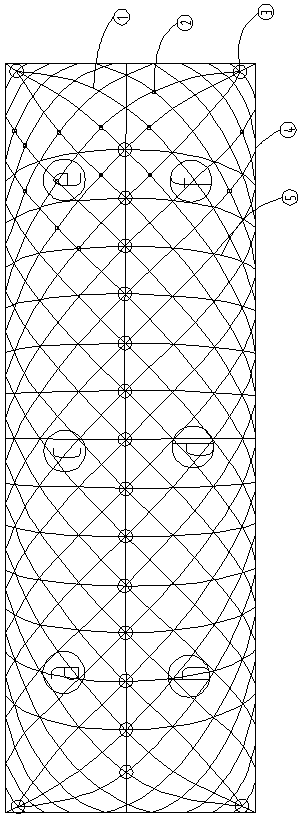

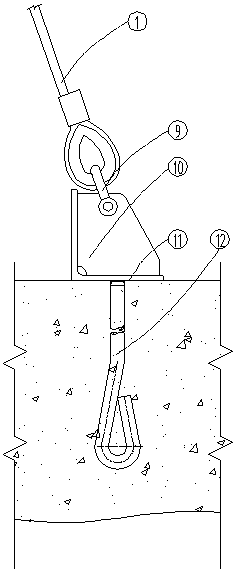

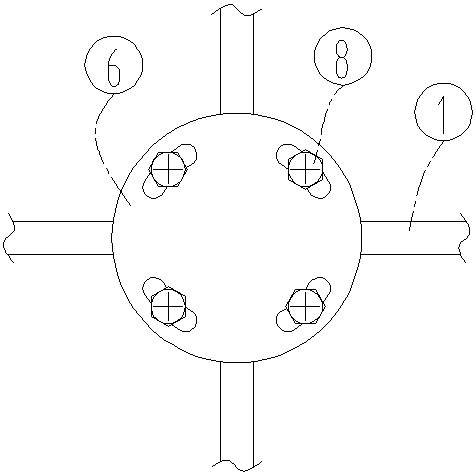

[0038] Such as Figure 1 to Figure 10 As shown, a combined steel cable net system of the present invention includes a steel cable net wrapped on the outer surface of a membrane building, and the bottom side of the steel cable net is anchored and connected to the foundation through an anchoring device 4 . The steel cable net is composed of several pieces of steel cable net as shown in a, b, c, d, e, f, and the steel cable net is composed of plastic-coated steel wire rope 1 through the node lock structure 2 in a scissors cross weave, A universal connection structure is provided at the joints of multiple steel wire ropes 1 between adjacent steel cable mesh sheets. The steel cable mesh is prefabricated in the factory, which reduces the workload on the construction site and improves the installation efficiency.

[0039] Several pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com