Three-dimensional water-cooled quenching car with bottom double-way water supply and working method thereof

A coke quenching vehicle and three-dimensional technology, applied in the field of coke quenching vehicles, can solve problems such as shortened life, prolonged coke quenching time, and easy damage to the central waterway, and achieve the effects of strengthening spray cooling, improving cooling efficiency, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

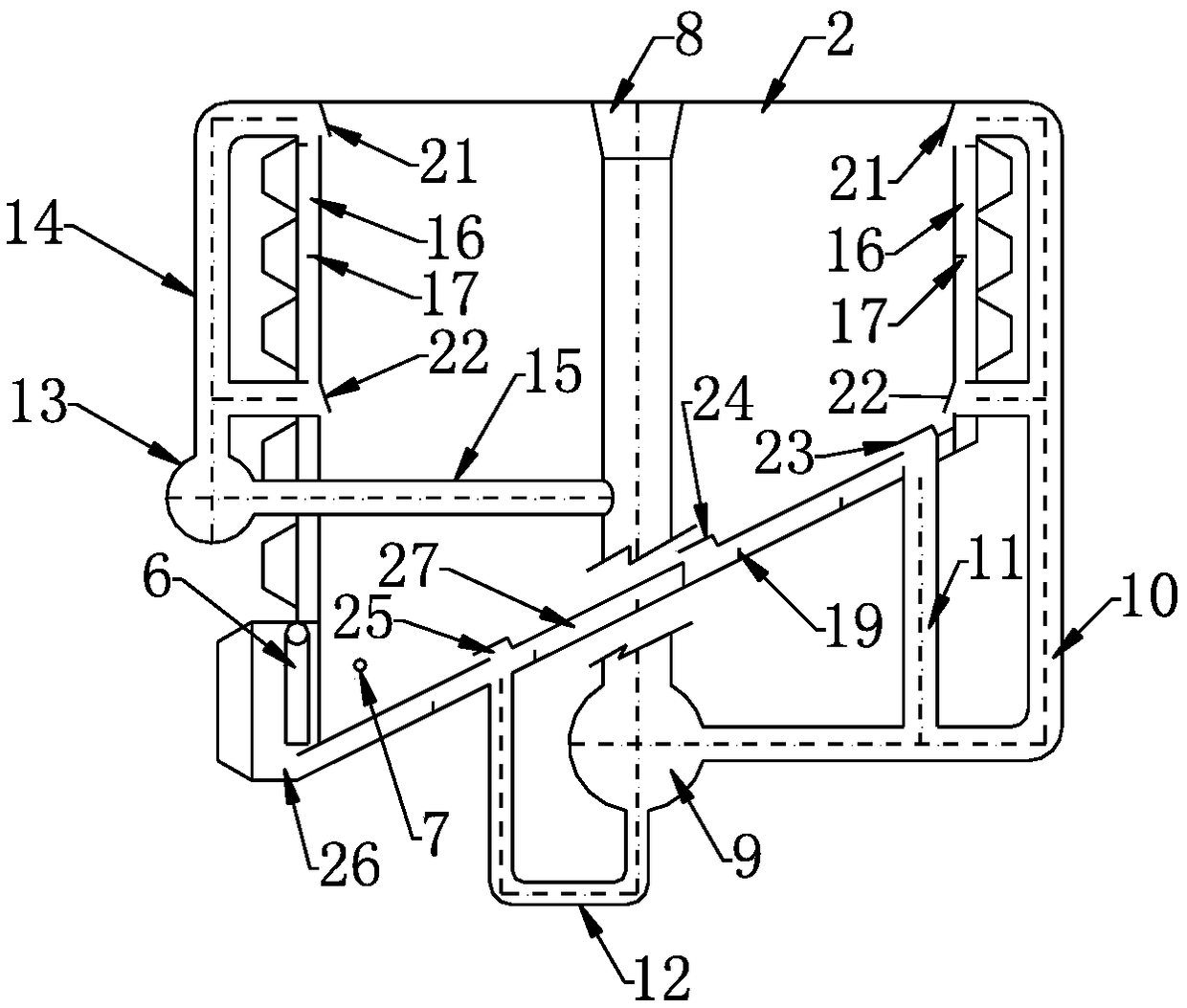

[0047] Such as Figure 1-Figure 4 As shown, a three-dimensional water-cooled coke quenching vehicle with two-way water supply at the bottom of the present invention includes a coke quenching vehicle composed of a vehicle body and a water injection system; the vehicle body consists of a left side panel 1, a right side panel 2, a front side Plate 3, rear side plate 4 and bottom plate 5 form a box-shaped structure with an open top and closed sides on the other five sides, wherein the left side plate 1 and right side plate 2 are respectively arranged on the lateral sides of the car body, and the front side plate 3 and the rear side Plates 4 are respectively arranged on the longitudinal sides of the car body; the bottom surface of the front side plate 3 is higher than the bottom surface of the rear side plate 4, so that the bottom plate 5 is inclined i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com