Automatic flushing device and method for paste resin polymerization kettle

An automatic flushing and pasty resin technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of increased difficulty in cleaning the kettle, inaccurate detection instrument blockage, and increased reaction time, etc., to achieve The effect of improving the utilization rate of the kettle, improving the quality and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

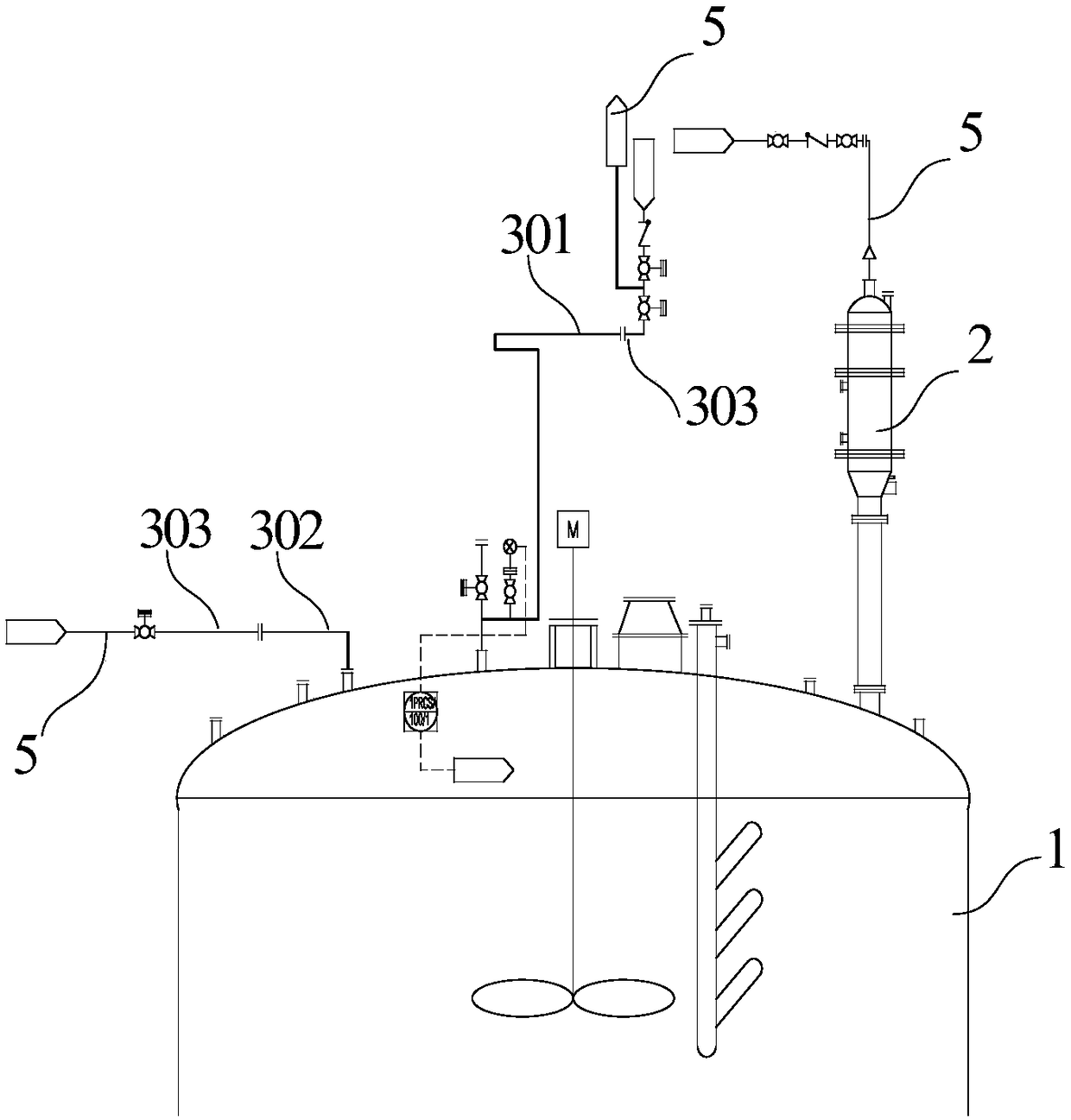

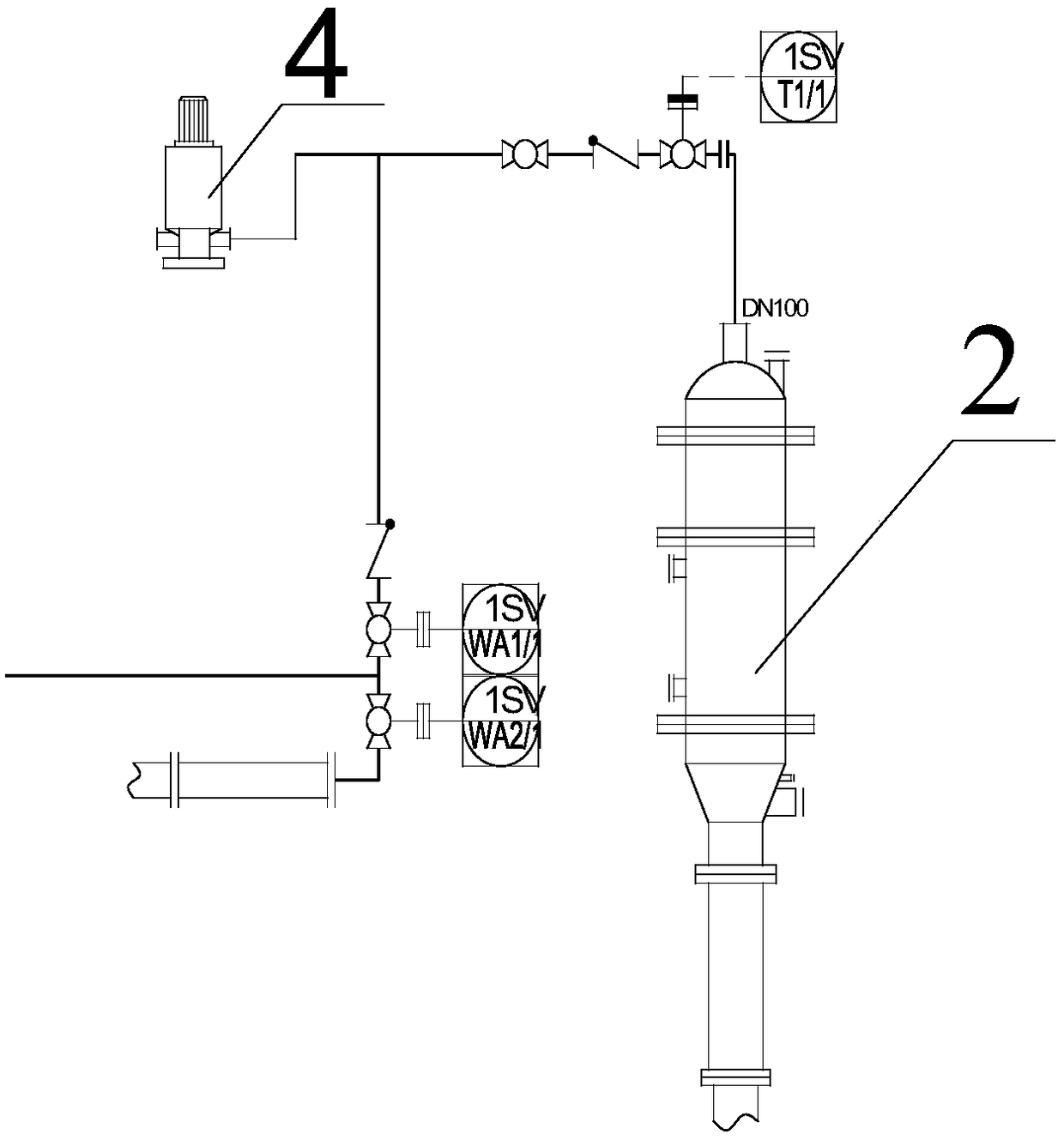

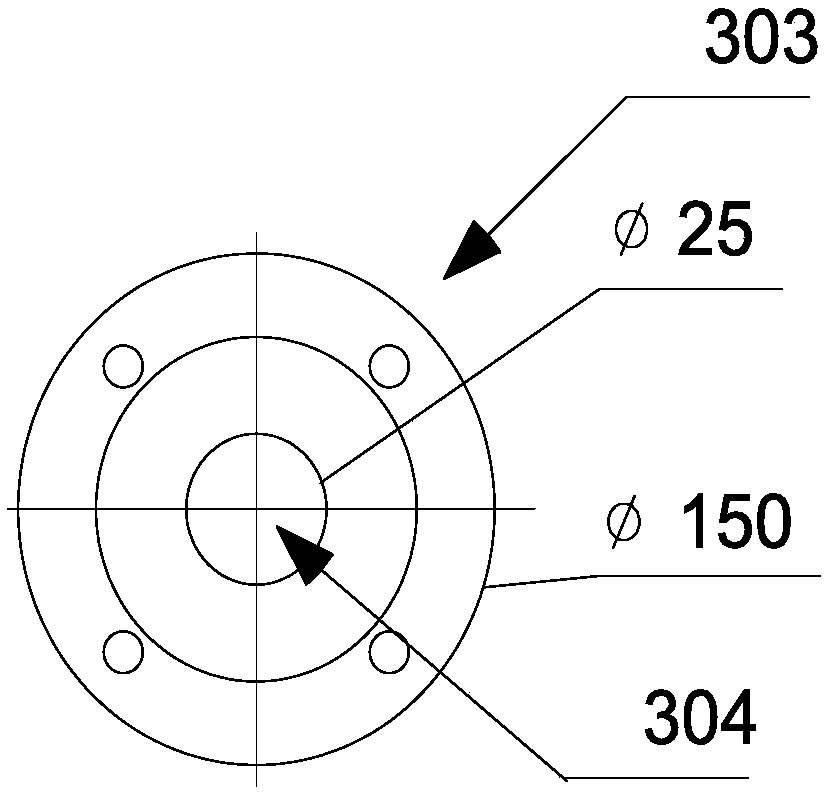

[0029] see figure 1 , an automatic flushing device for a paste resin polymerization kettle, comprising a multistage centrifugal pump and a high-pressure water pipe 5, the multistage centrifugal pump is arranged on the high-pressure water pipe pipeline to increase the water pressure; the polymerization kettle condenser is located at the polymerization kettle 1 At the top, the condenser 2 is a shell-and-tube type, with circulating cooling water in the shell side and non-condensable vinyl chloride monomer in the tube side; the water outlet end of the high-pressure water pipe 5 is set relatively.

[0030] The feed horizontal pipe connected with the high-pressure water pipe is the first feed horizontal pipe and the second feed horizontal pipe. The feed of the first feed horizontal pipe includes salt, seeds, and hot desalinated water. Materials include nitrogen, steam, compressed air.

[0031] The polymerization kettle 1 is connected with a feeding horizontal pipe, and for the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com