Intelligent speed-control blade type pipe cleaner

A technology for intelligent speed control and pigging, which is applied in the fields of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. Pipe efficiency, the effect of overcoming the problem of jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

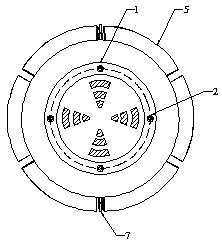

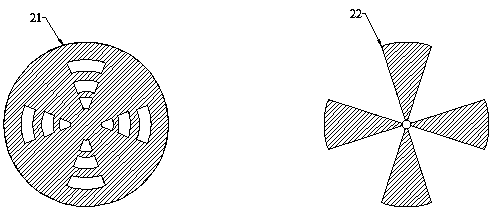

[0016] like figure 1 , figure 2 , image 3 As shown, the present invention is an anti-jamming and intelligent speed control pipe pig, which mainly consists of steel blade 5, polyurethane sheet 6, mileage wheel 7, spring leaf 8, mandrel 13, motor 15, single-chip microcomputer 16, speed The sensor 17, the pressure sensor 18, the discharge shaft 20, the discharge orifice 21, and the discharge baffle 22 are composed.

[0017] Specifically, before the present invention is used for production, a compression amount is preset for the spring leaf 8 according to the budgeted pigging pressure, and the spring tension is transmitted to the steel blade 5 through the slider 9 and the connecting rod 11. The preset compression amount Provide support for the steel blade 5 to ensure that the steel blade 5 has sufficient support along the radial direction of the pipeline, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com