A rivet quality rating and automatic sorting system and method

An automatic sorting system and rivet technology, applied in sorting and other directions, can solve the problems of no rating and screening process, low detection efficiency, single type of rivets, etc., to reduce the influence of external light, high measurement accuracy, hardware cost and structure. low-complexity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

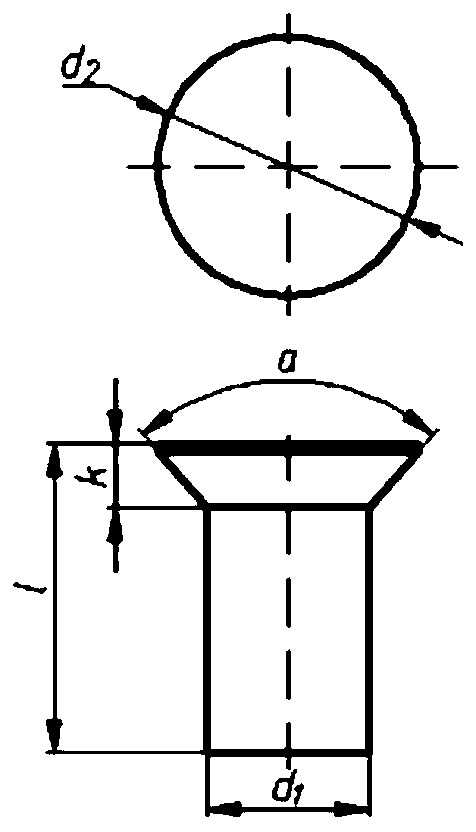

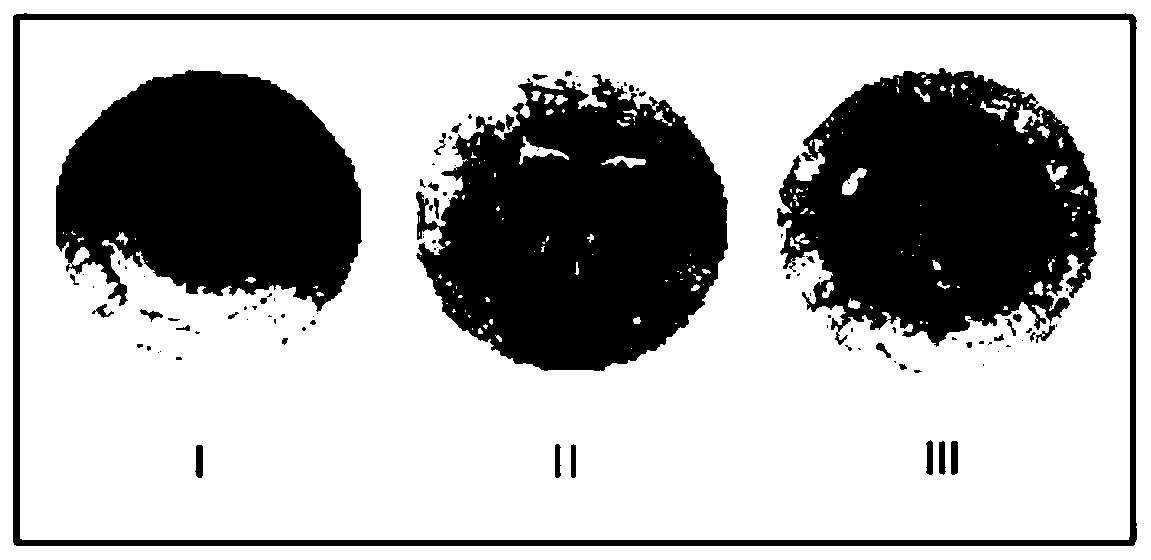

[0067] This embodiment provides a rivet quality rating and automatic sorting system, including a material delivery device 1, a detection device 2, a screening device 3 and an automatic control unit; the material delivery device 1 is used to deliver rivets 5 to the detection device, and Output the rivet 5 after the detection to the screening device 3; the detection device 2 includes a clamping mechanism 21 and an information collection mechanism 22, the clamping mechanism 21 includes a pneumatic finger 210 and a pneumatic turntable 211, and the two free ends of the pneumatic finger 210 are A first gripping plate 212 and a second gripping plate 213 are respectively provided on the first finger, and the pneumatic finger 210 controls the first gripping plate 212 and the second gripping plate 213 to open or close together for the rivet 5;

[0068] The pneumatic finger 210 is connected to the pneumatic turntable 211, specifically, the pneumatic finger 210 is connected to the pneumati...

Embodiment 2

[0077] Further improvement on the basis of Embodiment 1, the material conveying device 1 includes a vibrating plate 11 and a conveyor belt 12, the output end of the vibrating plate 11 is connected to the input end of the conveyor belt 12, the conveyor belt 12 is located below the pneumatic finger 210, and the conveyor belt 12 Used to transport rivets 5. The conveyor belt 12 is provided with a photoelectric switch 13 near the side of the pneumatic finger 210, and the photoelectric switch 13 is used to detect the position of the rivet 5 on the conveyor belt 12, and transmits the detection information to the PLC controller, and the PLC controller according to the detection information The clamping mechanism 21 is controlled to complete the clamping action.

Embodiment 3

[0079] Further improvement on the basis of Embodiment 2, the first grasping plate 212 and the electronic ruler 220 of the pull rod are fixed on one of the finger ends of the pneumatic finger 210 through the first connecting bar 214, specifically, the electronic ruler 220 of the pull rod passes through the base 228 and The L-shaped bracket 229 is fixed on the first connecting bar 214; the second grasping plate 213 and the distance measuring plate 222 are fixed on the other finger end of the pneumatic finger 210 by the second connecting bar 215; the first connecting bar 214 and the second connecting bar 215 are C-shaped structures. The information collection mechanism 22 also includes a square light source 223 and a ring light source 224, the square light source 223, the ring light source 224 and the camera 221 are sequentially arranged on a straight line; when the camera 221 takes pictures to collect graphic information, the rivet 5 is located on the straight line . The inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com