Vibrating screening equipment for refractory granular materials

A technology of screening equipment and refractory materials, applied in the fields of sieves, solid separation, chemical instruments and methods, etc., can solve the problems of inability to accurately control the particle size classification and screening of crushed materials, high labor intensity, low efficiency, etc., to save manpower , the effect of high degree of automation and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

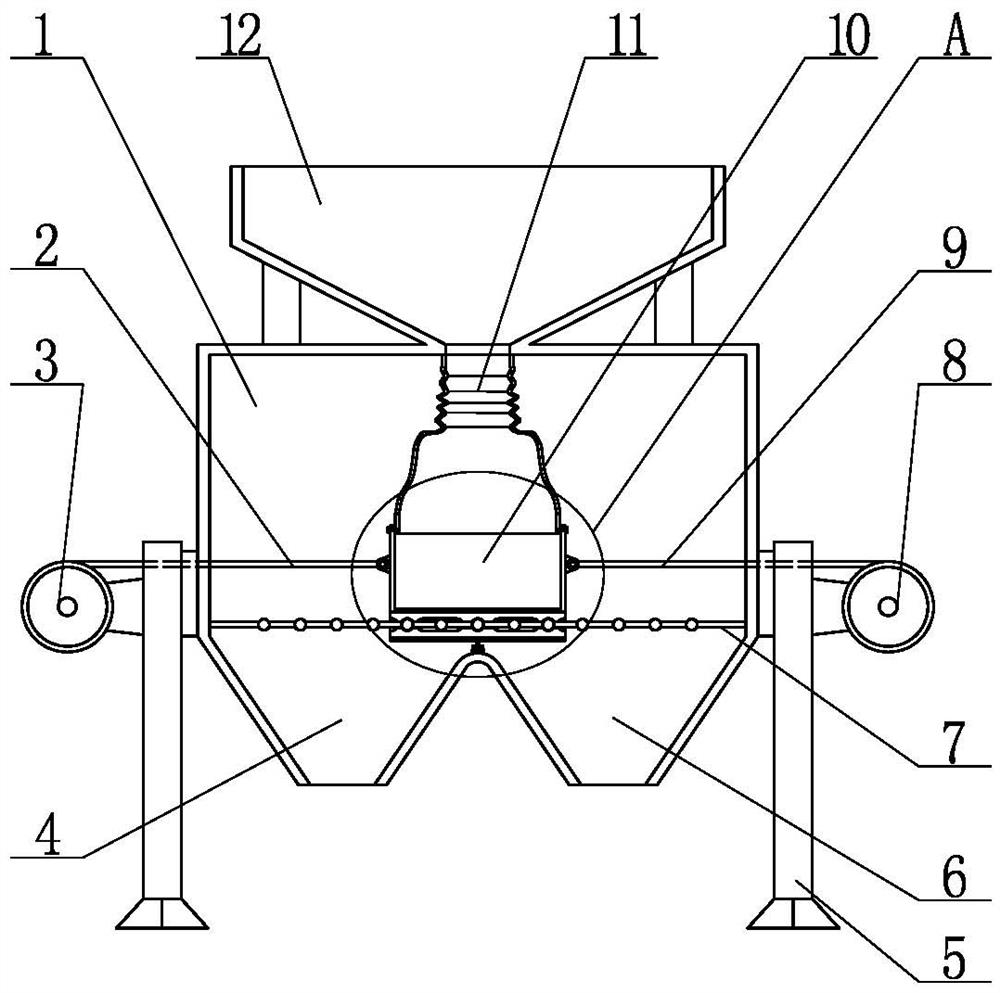

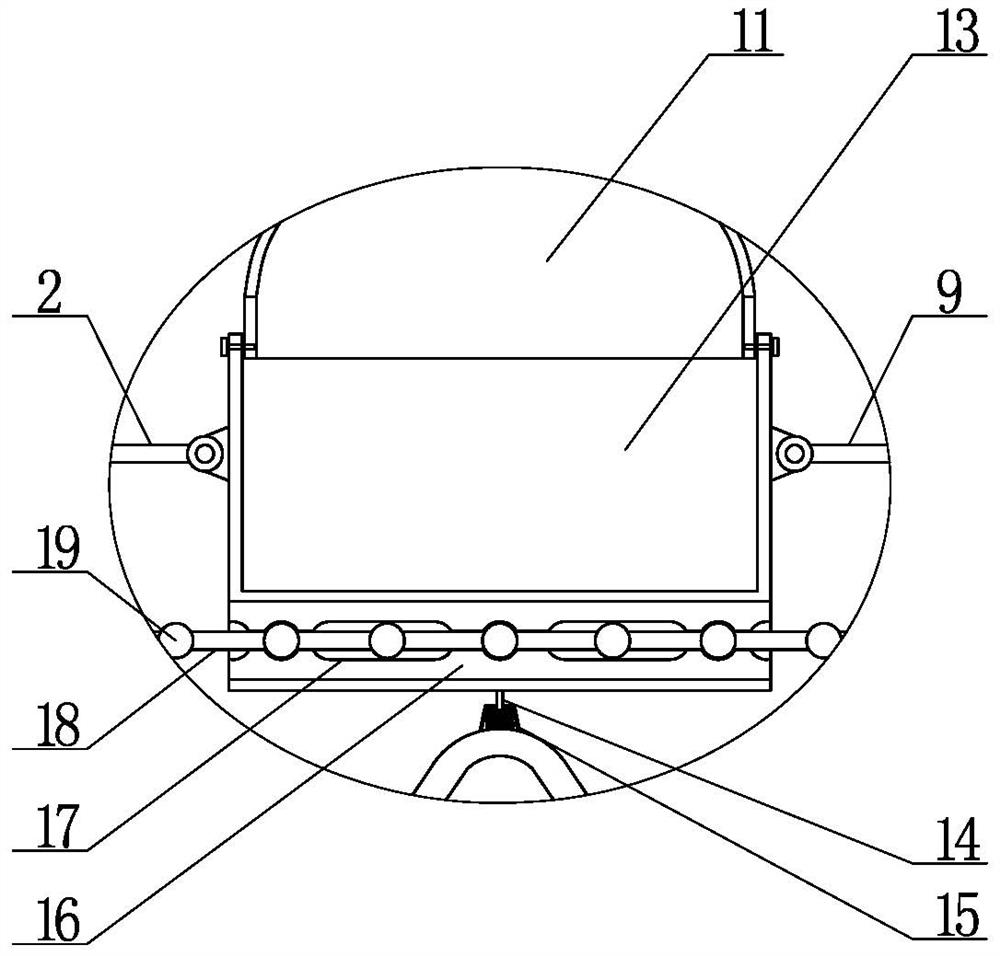

[0018] Such as figure 1 As shown in the present invention, a kind of vibrating screening equipment for refractory material granular materials according to the present invention includes a frame, a discharge funnel is arranged on the frame, a distribution bin is arranged below the discharge funnel, and in the distribution bin A particle size screening device is set, the upper end of the particle size screening device is connected to the lower outlet of the discharge funnel through a flexible connecting pipe, and the particle size screening device is connected to the vibration sliding drive device; The fine material outlet and the coarse material outlet are respectively set on the side.

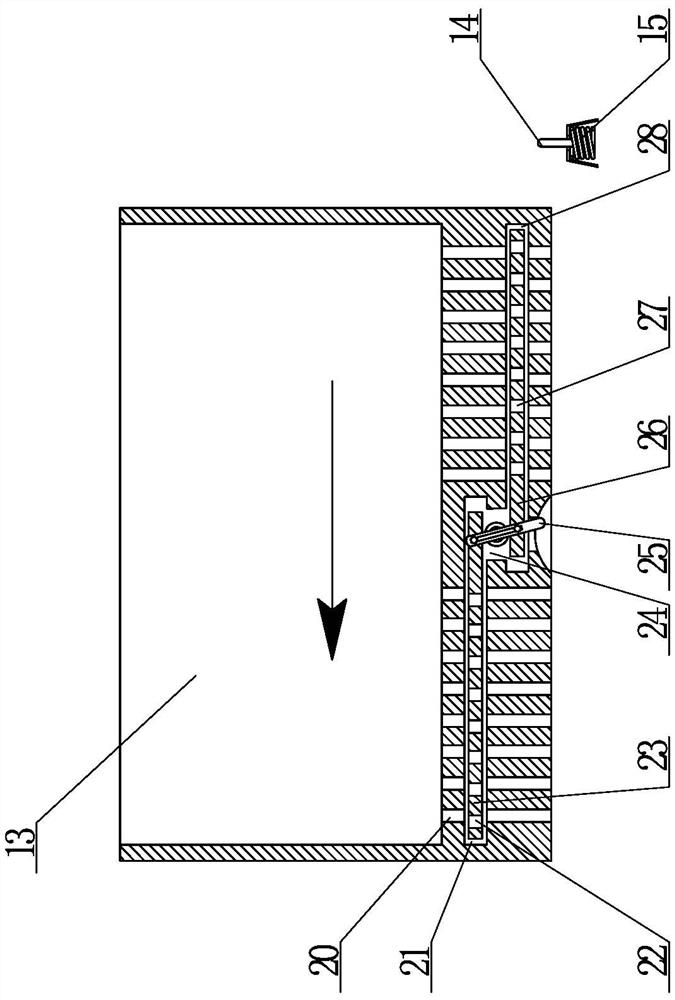

[0019] The particle size screening device includes a square cylindrical mobile screening bin with an open upper end, the upper opening of the mobile screening bin is sealed and connected with the lower end of the flexible connecting pipe; the bottom of the mobile screening bin is set Aperture-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com