Printing and dyeing raw material mixer

A technology for mixers and raw materials, applied in mixers, jitter/oscillation/vibration mixers, mixers with rotating stirring devices, etc., can solve the problem that fixed blocks are installed on the bottom of the movable plate through fastening screws, and the movable block and The fixed blocks are connected by the second connecting rod, and the edge of the movable plate away from the fixed plate is provided with a vertical support frame. The internal installation of the support frame cannot simulate manual stirring, etc., so as to increase the effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

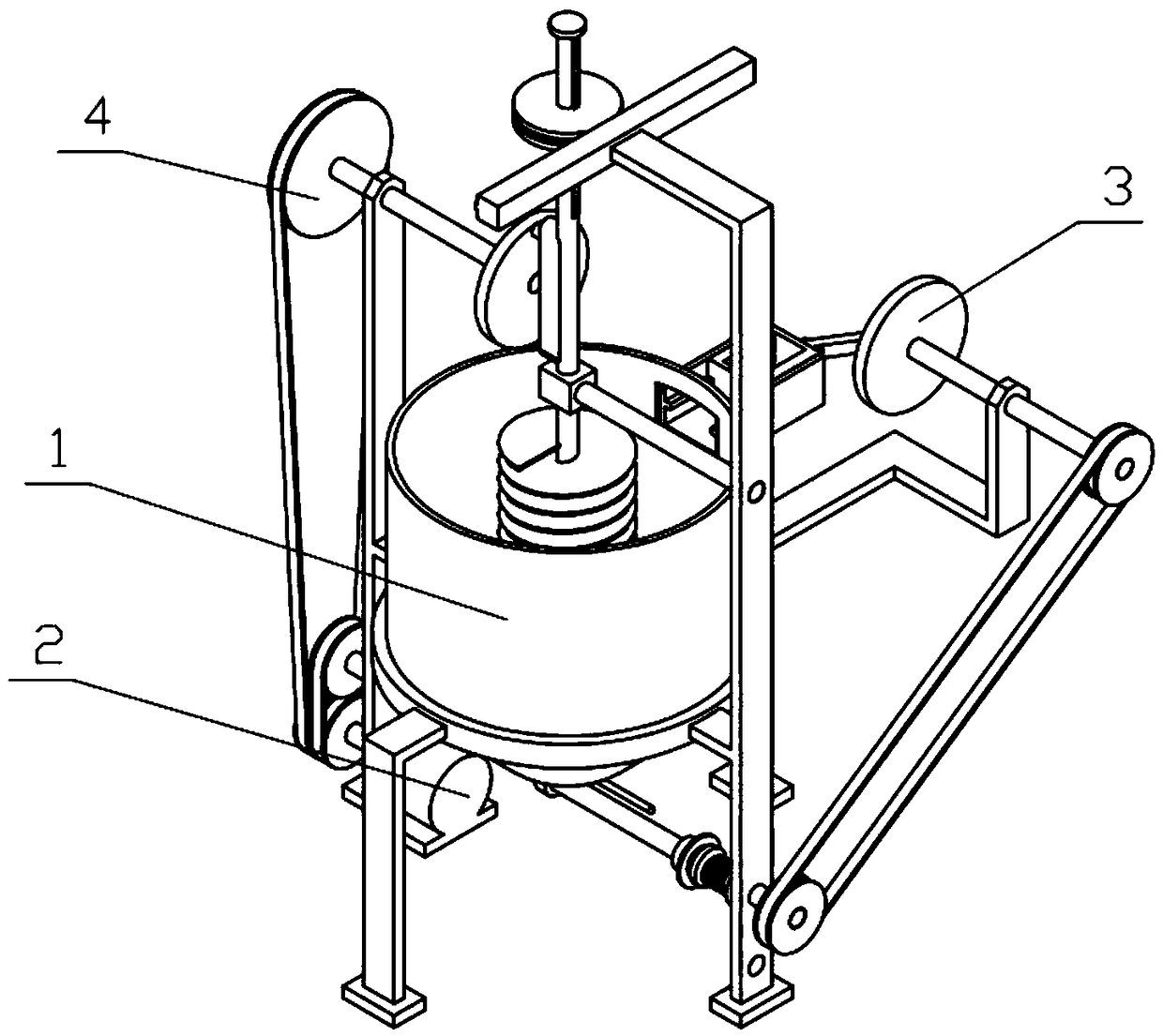

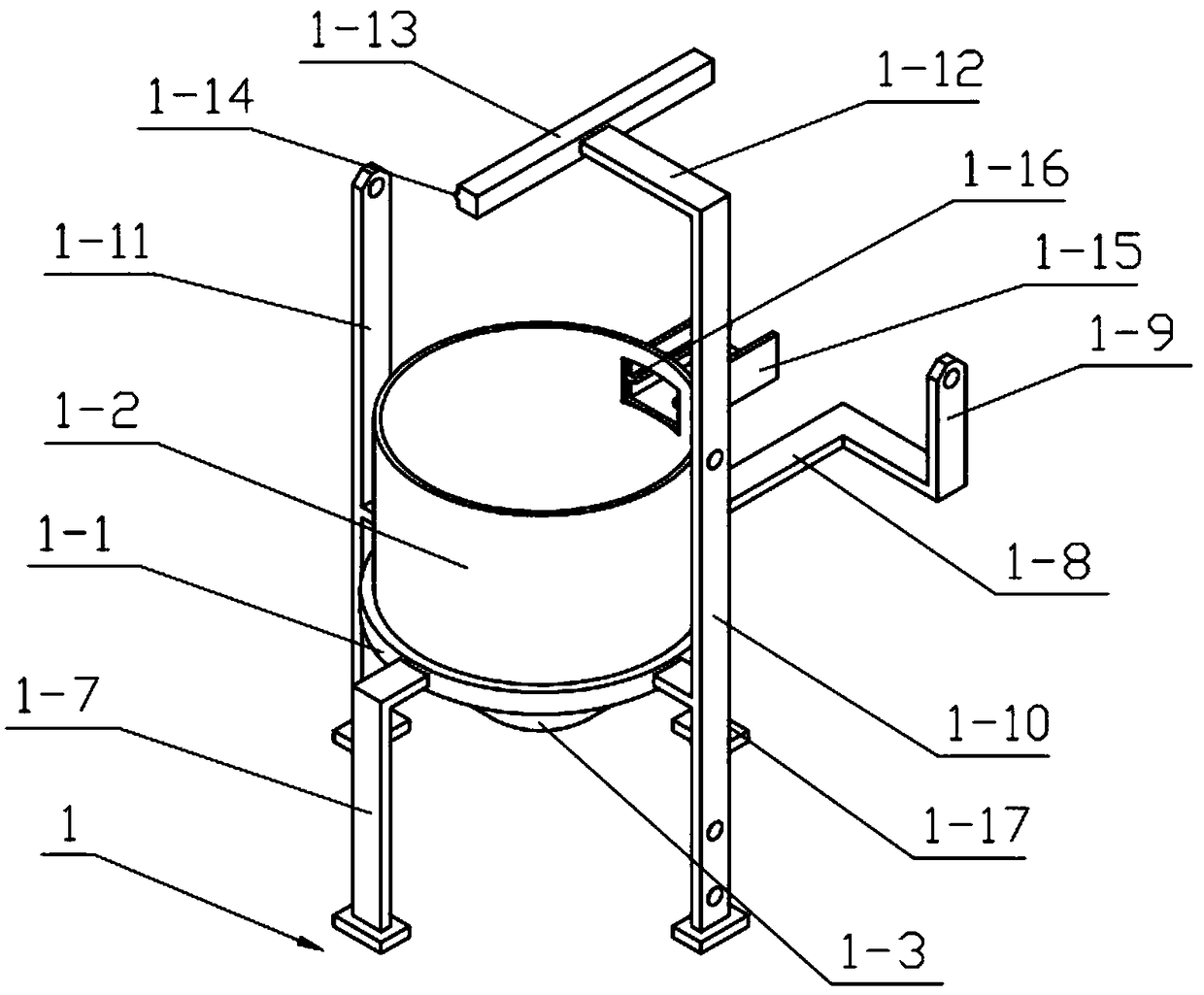

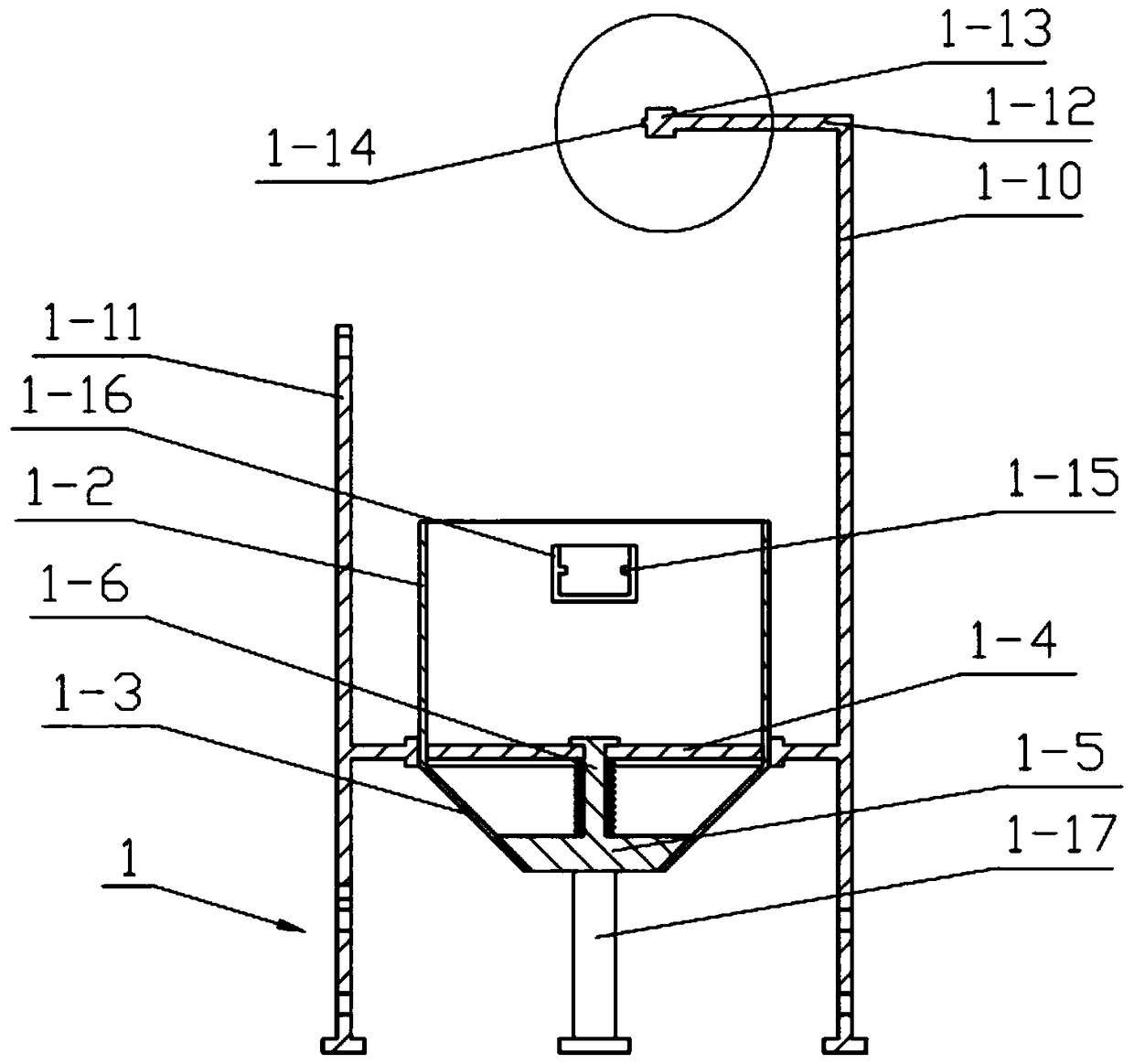

[0029] Combine below Figure 1-10 Describe this embodiment, a printing and dyeing raw material mixer, including the whole machine support 1, power mechanism 2, feeding mechanism 3 and stirring mechanism 4, can drive the feeding mechanism 3 and stirring mechanism 4 to move simultaneously through the power mechanism 2, through The threaded cylinder 2-6 set on the power mechanism 2, the push threaded rod 2-7 and the sliding cylinder 2-8 can realize the timing transmission of the power mechanism 2, and control the time when the power mechanism 2 drives the feeding mechanism 3 to move and control the amount of feed. how much; by the diameter of the stirring pulley 4-2 greater than the diameter of the power pulley 2-2, the effect of speed reduction and twisting is played so that the power on the power mechanism 2 is suitable for the power required by the stirring mechanism 4, and the stirring mechanism 4 is in the following The axis of the stirring shaft III 4-12 arranged on it rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com