Flue gas denitration agent

A denitrification agent and flue gas technology, applied in the field of flue gas denitration agent, can solve problems such as low cooling efficiency, and achieve the effects of reducing overall cost, reducing dosage, and increasing adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

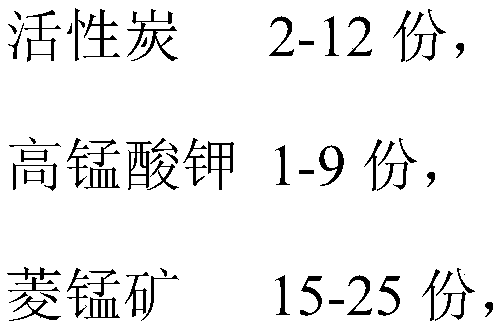

[0033] A flue gas denitrification agent, the denitrification agent comprises the following components:

[0034]

[0035] The above-mentioned parts are all parts by weight.

Embodiment 2

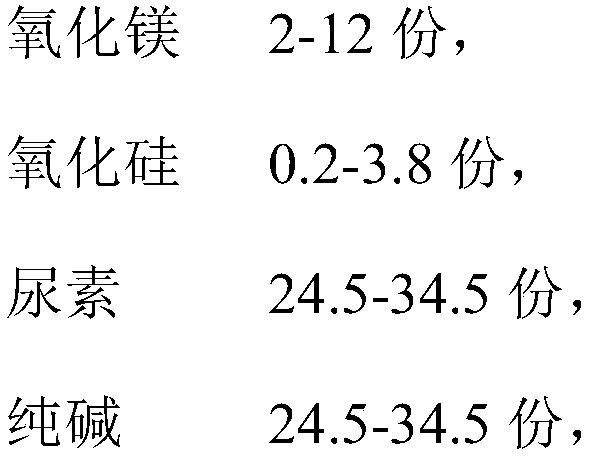

[0037] A flue gas denitrification agent, the denitrification agent comprises the following components:

[0038]

[0039]

[0040] The above-mentioned parts are all parts by weight.

Embodiment 3

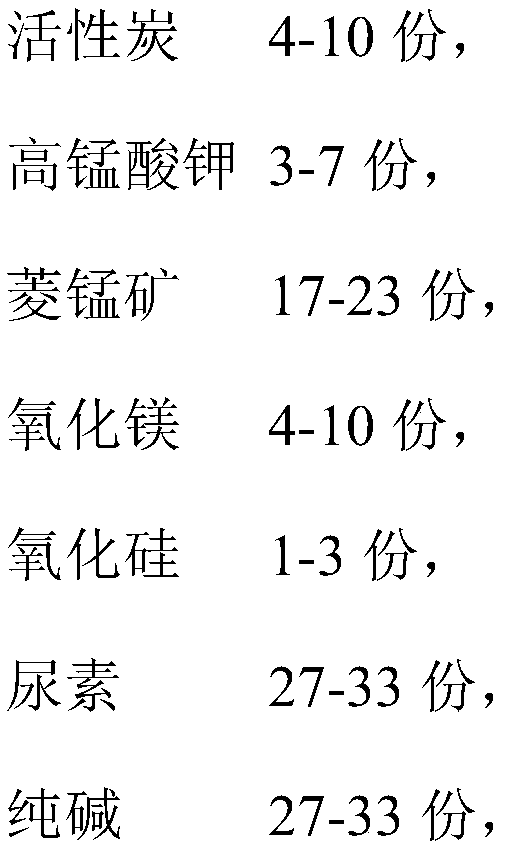

[0042] A flue gas denitrification agent, the denitrification agent comprises the following components:

[0043]

[0044] The above-mentioned parts are all parts by weight.

[0045] Specifically, the main component of rhodochrosite powder is manganese carbonate, and it also contains some metal substances, such as Fe, Ca, Zn and Mg, etc., which can play a role in decomposition in the denitrification reaction, and can further improve the denitrification effect and efficiency.

[0046] In addition, the main component of soda ash is Na 2 CO 3 , which can interact with NO in water 2 The reaction forms NaNO 3 and CO 2 , reacts with NO in water to form NaNO 2 and CO 2 , to remove nitrogen oxides (NO X ) role.

[0047] In addition, a small amount of Al can be added to the denitrification agent 2 o 3 , BaO, SiO 2 and other metal oxides play a role in decomposition.

[0048] The denitrification partial reaction formula is:

[0049] CO(NH 2 ) 2 +2NO=2H 2 +CO 2 +2H 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com