An inspection device

A technology for inspecting devices and inspecting objects, applied to measuring devices, material analysis through optical means, instruments, etc., can solve problems such as complex calculations and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

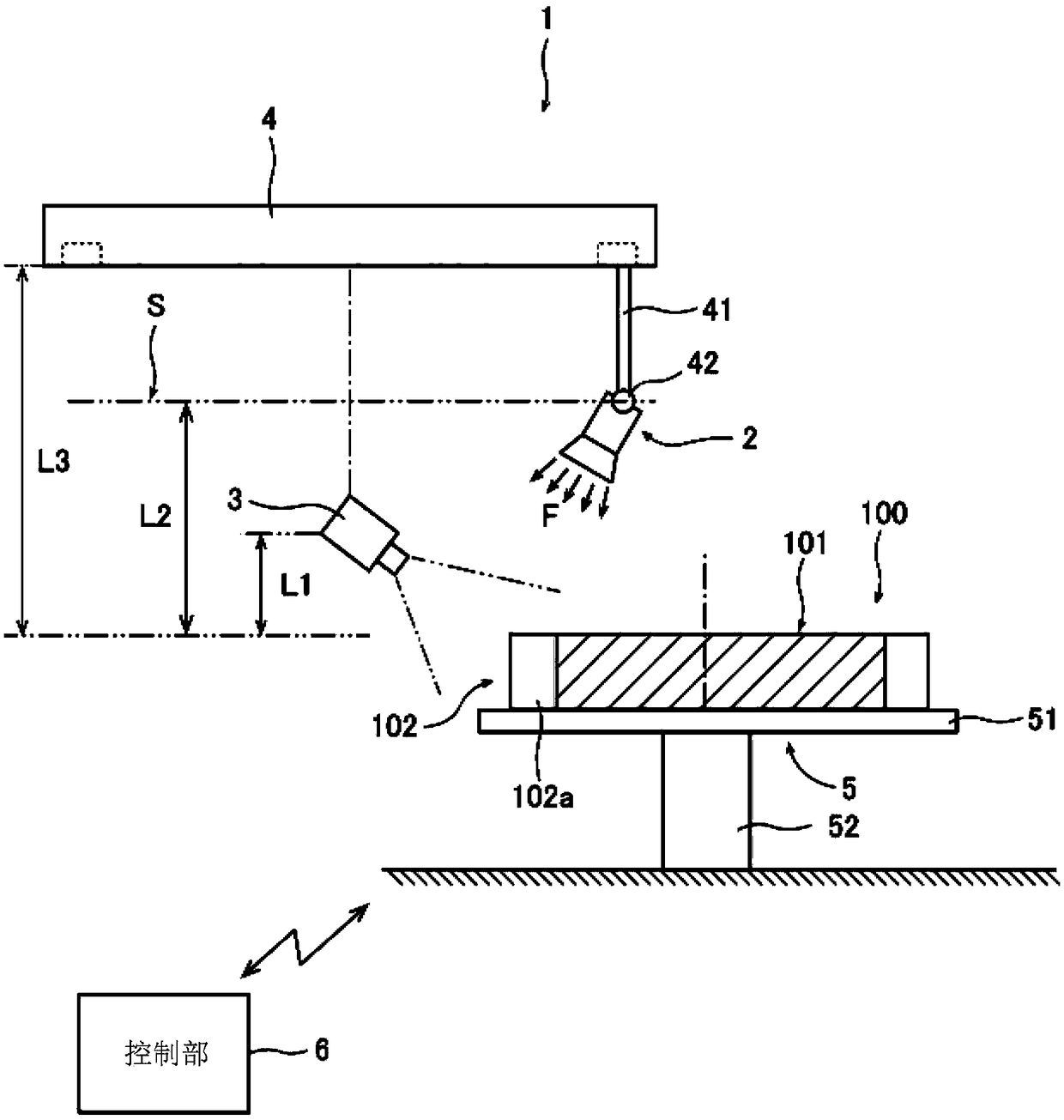

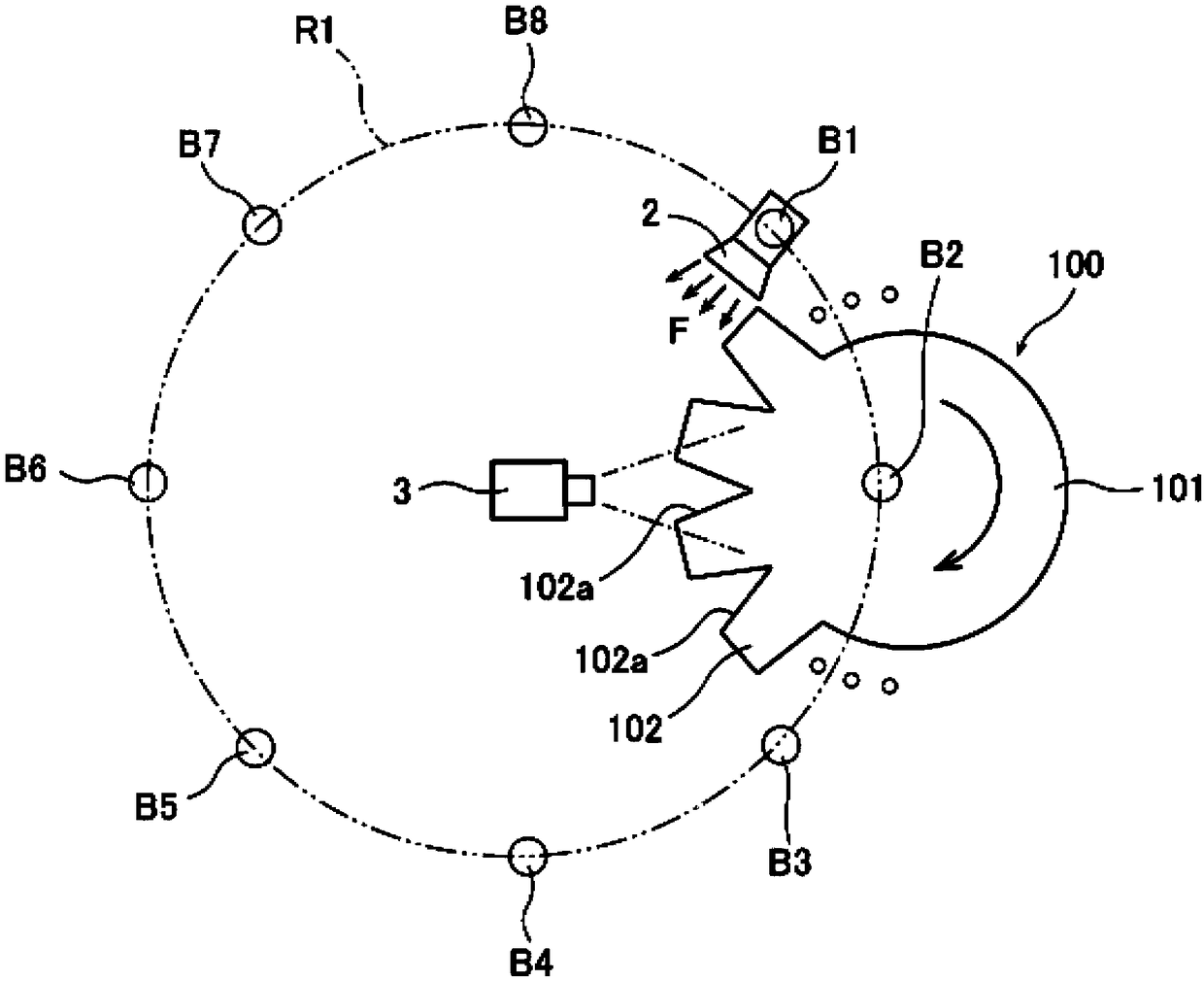

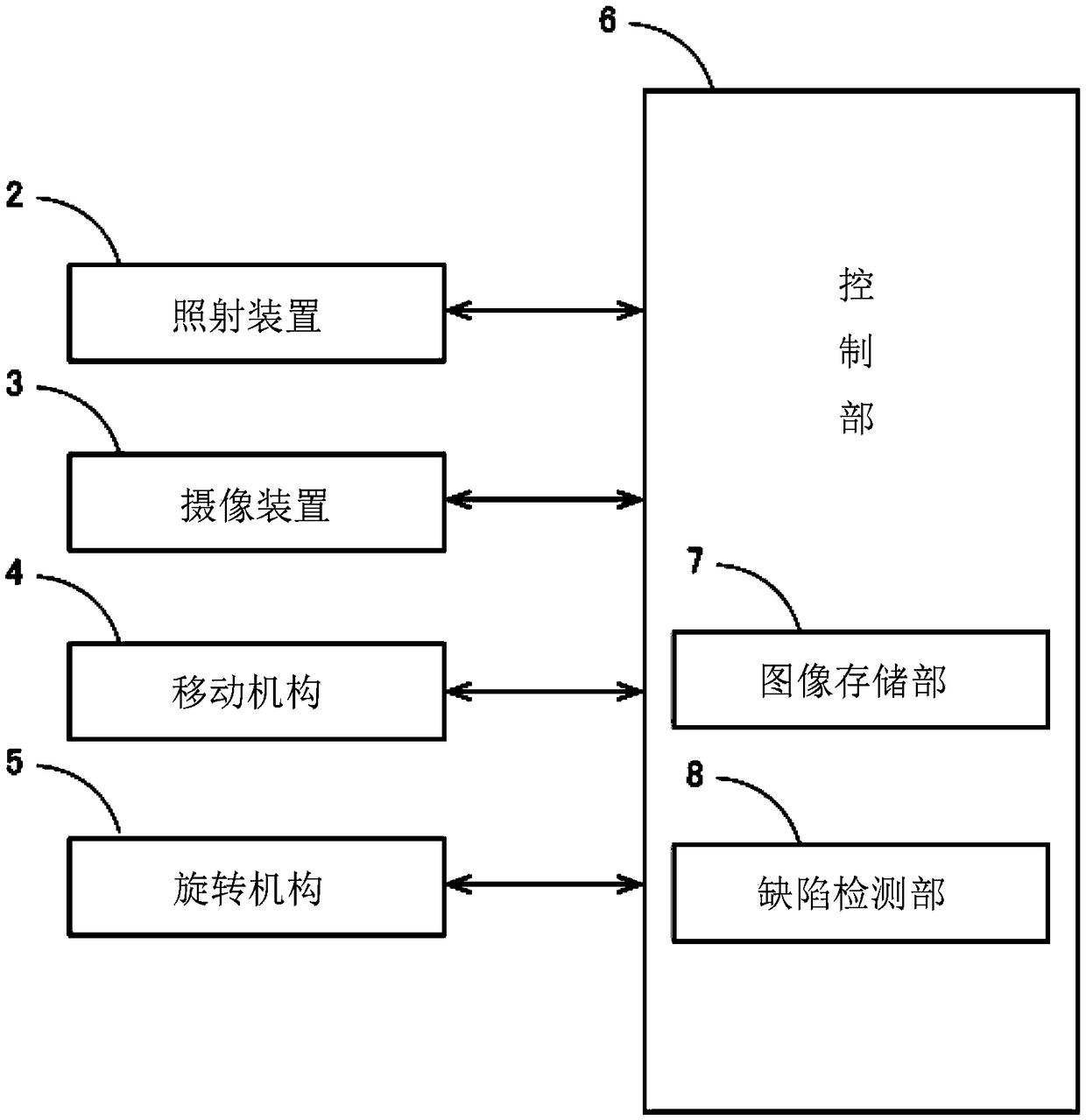

[0021] Next, exemplary embodiments of the inspection device and inspection method of the present invention will be described with reference to the drawings. The inspection device and inspection method of the present invention are devices and methods for performing visual inspection of a surface to be inspected included in an outer peripheral surface of an object to be inspected. Hereinafter, the direction parallel to the thickness direction and axis of the object to be inspected is called "axial direction", and the direction perpendicular to the axial direction is called "radial direction". The direction of is called "circumferential direction" for illustration.

[0022]

[0023] The inspection device 1 of the present embodiment automatically performs an appearance inspection for detecting defects such as dents on the surface of an inspection object 100 having a thickness in the axial direction. More specifically, the inspection object 100 of the present embodiment has a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com