Clutch test device

A test device and clutch technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of many types of mechanical clutches, frequent tests, high energy consumption, etc., achieve convenient adjustment and adaptation, and reduce test costs , the effect of investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

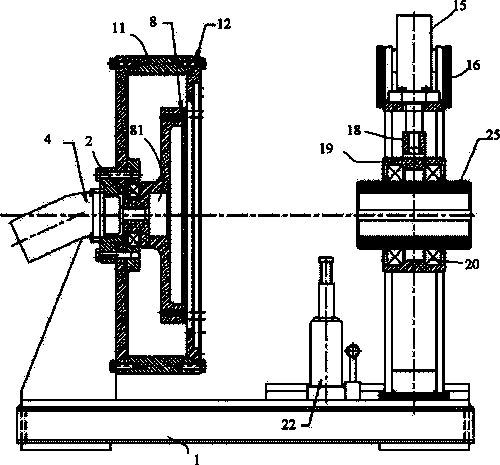

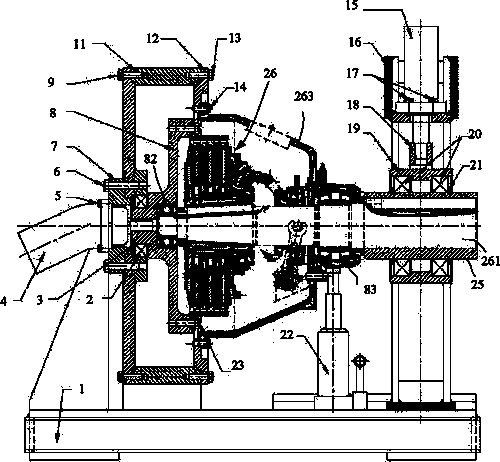

[0012] like Figure 1-Figure 2 As shown, the present invention schematically shows a clutch test device.

[0013] The invention discloses a clutch test device, such as figure 1 and figure 2 As shown, the mechanical clutch side-load non-torque test device includes a fixed support plate 1, a simulated engine casing 11 supported on the fixed support plate 1, a motor 4 supported on the simulated engine casing 11, a rotatable support The flywheel connection device 8 on the simulated engine housing 11 , the height adjustment support device 22 supported on the fixed support plate 1 , and the pressure adjustment device supported on the fixed support plate 1 .

[0014] The outer side of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com