Nuclear secondary tight-sealing high-temperature medium combined gate

A high-temperature medium and gate technology, applied in sliding valves, engine components, mechanical equipment, etc., can solve problems such as fire or explosion, and achieve the effect of preventing medium leakage and ensuring sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings.

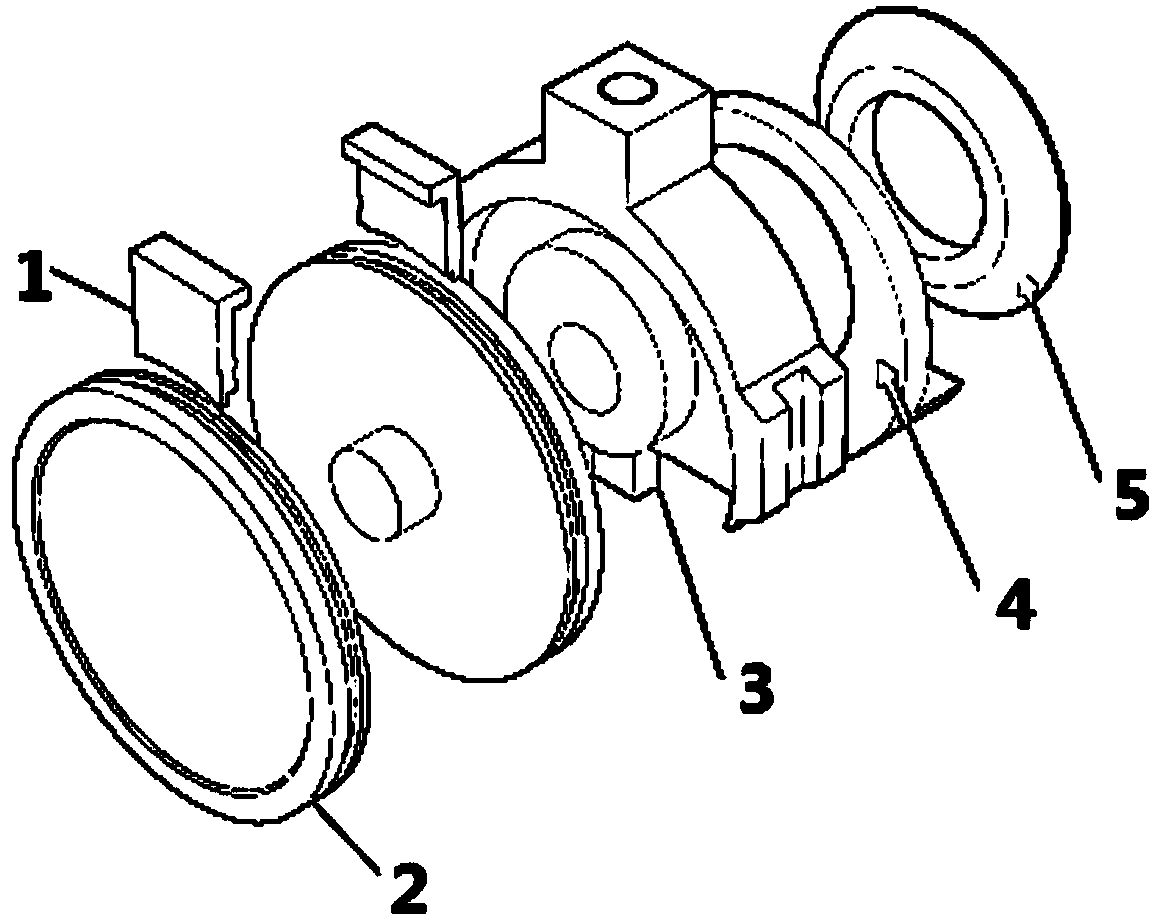

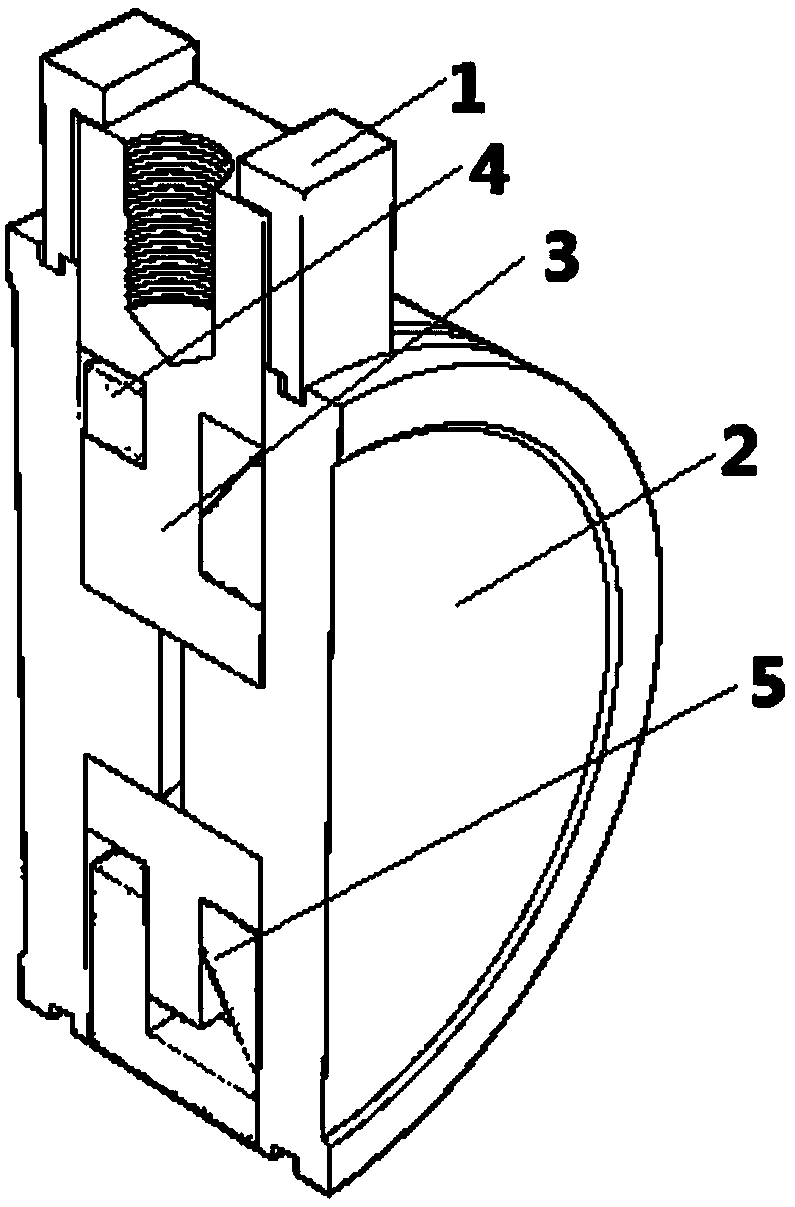

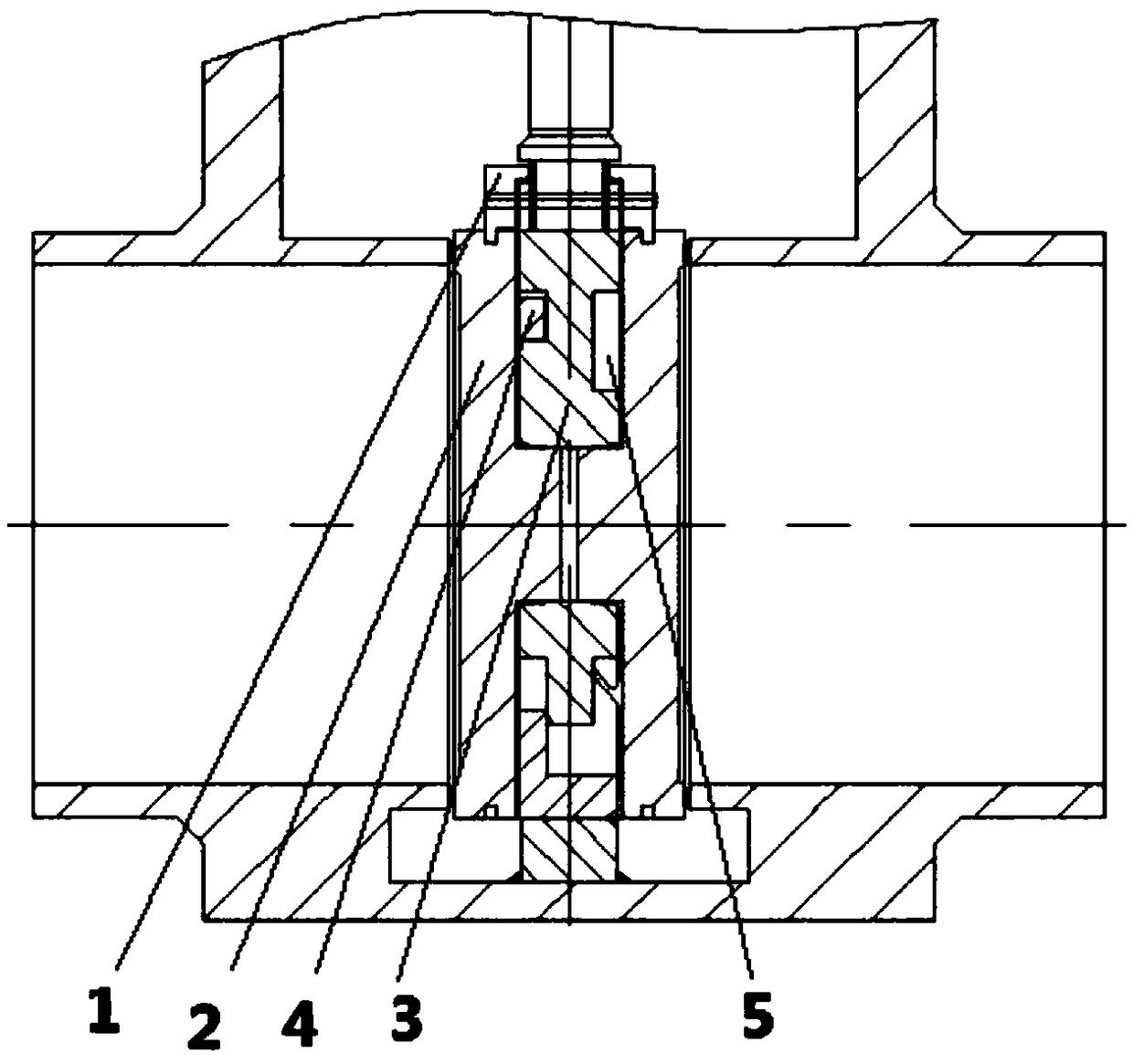

[0015] Please refer to the attached figure 1 , The device is composed of five components, including a limit clip 1, a side gate 2, a gate bracket 3, a limit left wedge 4 and a limit right wedge 5. The connection sequence is assembled with the gate bracket 3 as the center point; secondly, the limit left wedge plate 4 and the limit right wedge plate 5 are installed in the groove of the gate bracket 3 and closely attached to the inner surface to ensure that the left and right sides are parallel. The center of the center hole of the wedge plate 4 is not concentric with the gate bracket 3 and is in a state of incision; then the side gate 2 is assembled in the center hole of the gate bracket 3, and is in contact with the left and right sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com