Rubber gasket

A technology of rubber gasket and gasket body, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., and can solve the problems of installation quality impact, narrow operating space, and increased working hours and work intensity of installers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

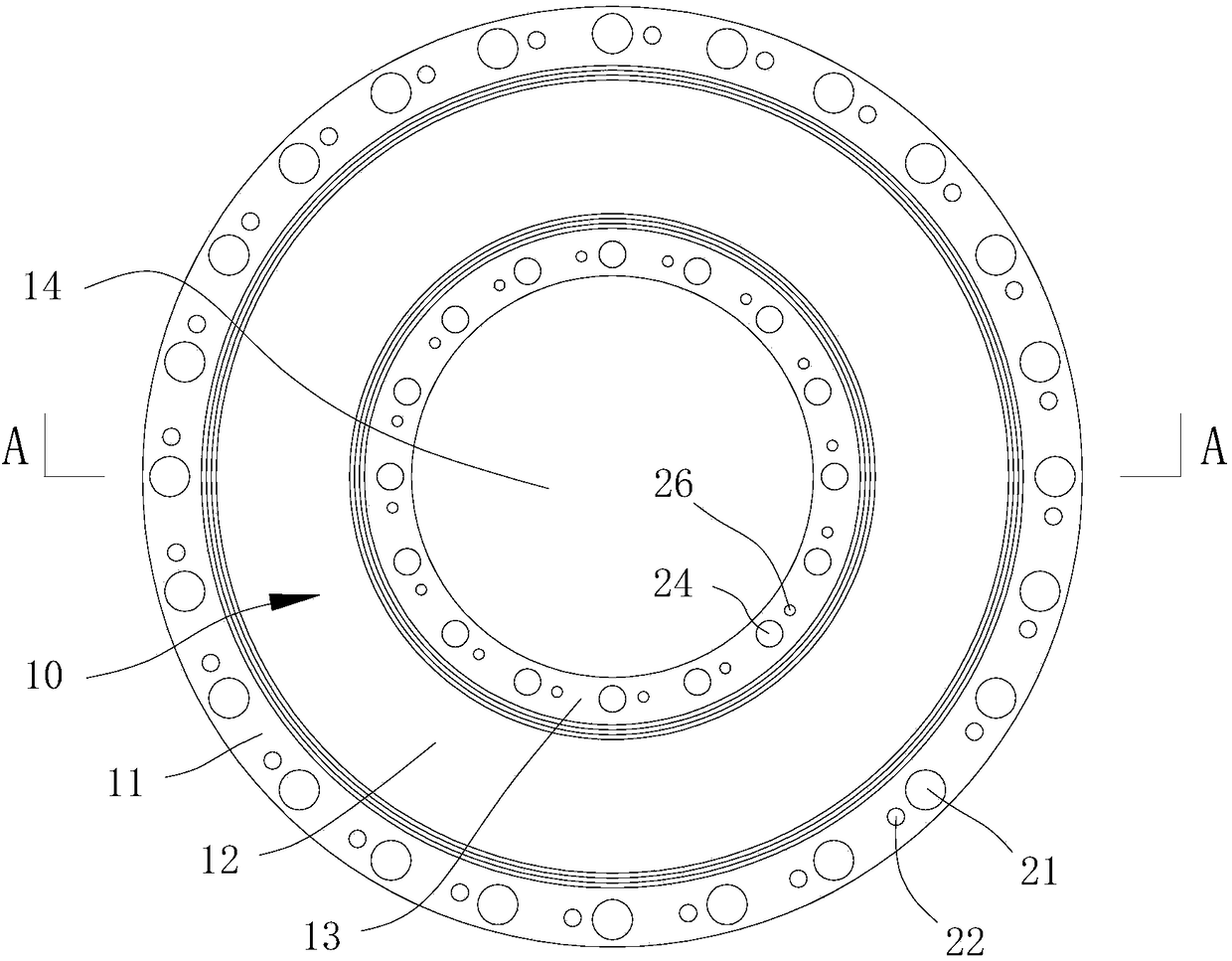

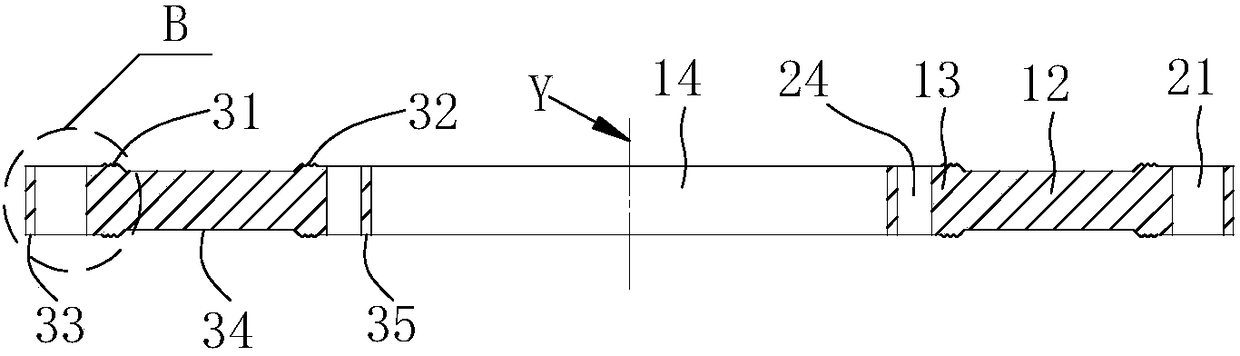

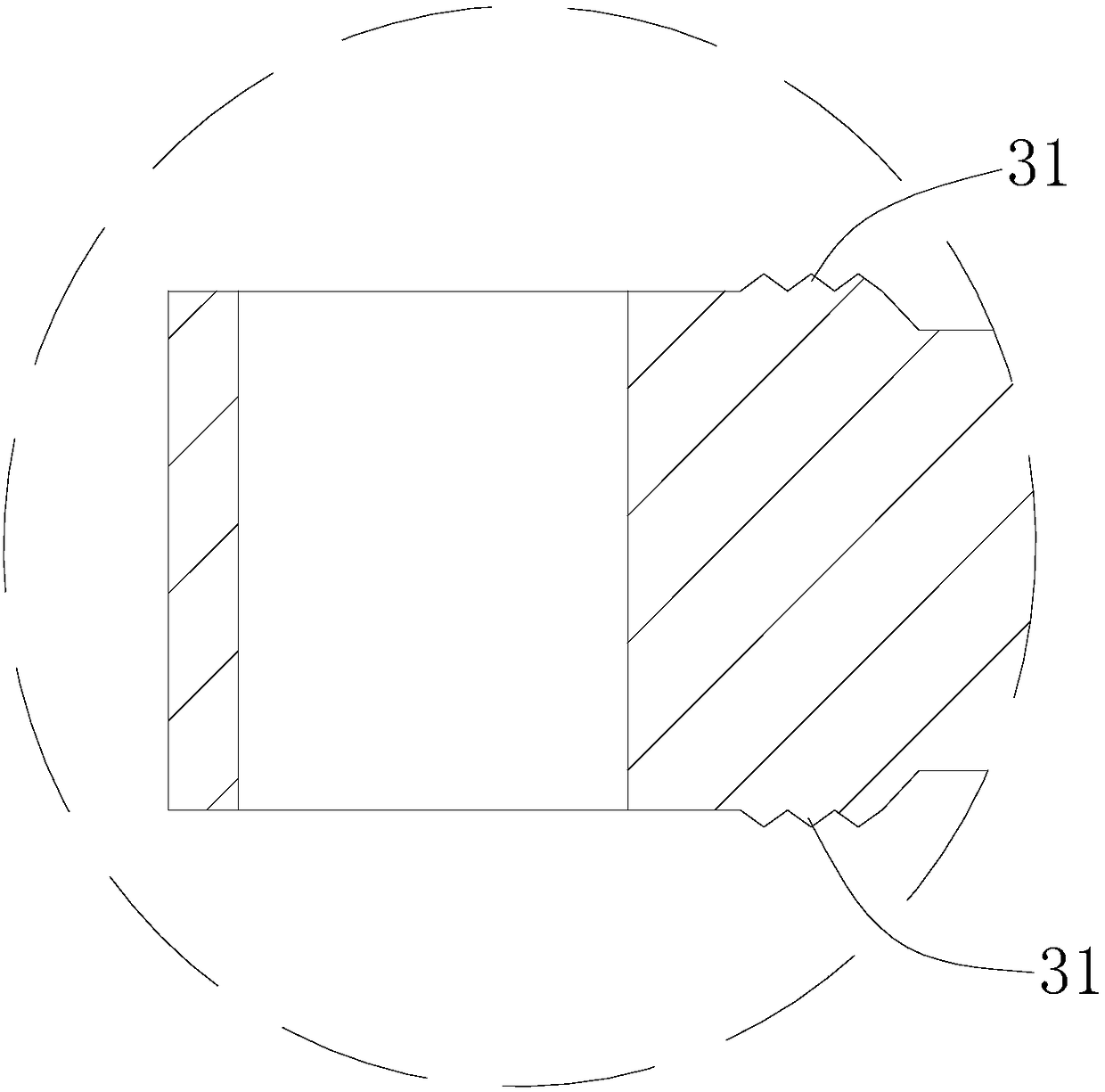

[0014] refer to Figure 1 ~ Figure 3 , a rubber gasket, which includes a ring-shaped gasket body 10, the gasket body 10 includes a first gasket 11, a second gasket 13 located inside the first gasket 11, and a connection between the first gasket 11 and the second gasket. The middle ring body 12 of the washer 13; on the first washer 11, several sets of outer ring holes are evenly arranged around the central axis Y of the washer body 10, and each set of outer ring holes includes a first fixing hole 21 for passing through bolts and a first positioning hole 22 for positioning, the center of the first fixing hole 21 and the first positioning hole 22 are located on the same circle; on the second washer 13, several groups are evenly arranged around the central axis Y of the gasket body 10 Inner ring holes, each set of inner ring holes includes a second fixing hole 24 for passing through bolts and a second positioning hole 26 for positioning, the centers of the second fixing hole 24 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com