Continuously variable transmission control system for rolling vehicle

A technology of stepless speed change and control system, applied in the direction of transmission control, transmission, transmission parts, etc., can solve the problems of small gear range, easy gear setback, and high transmission loss, etc., to achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

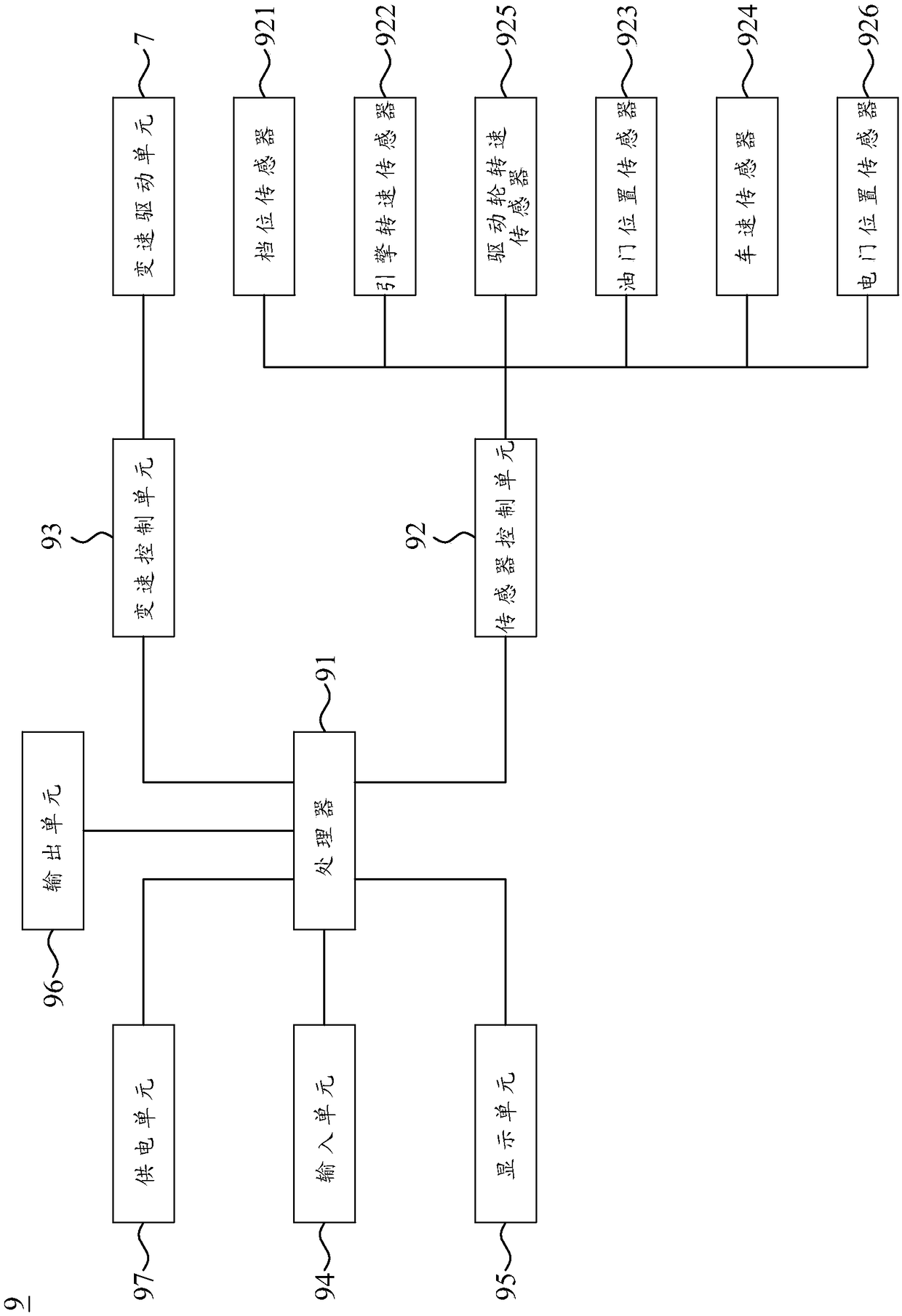

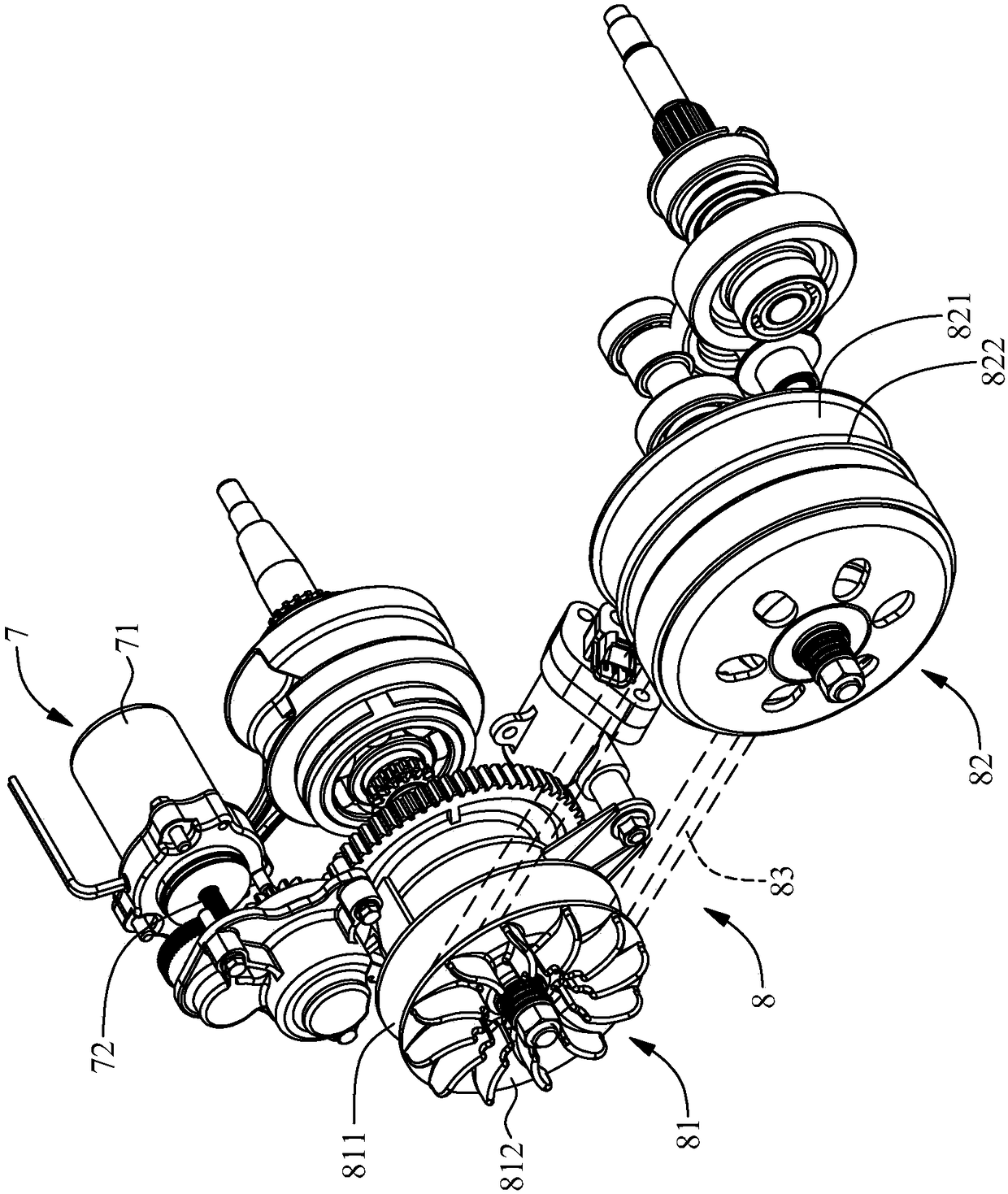

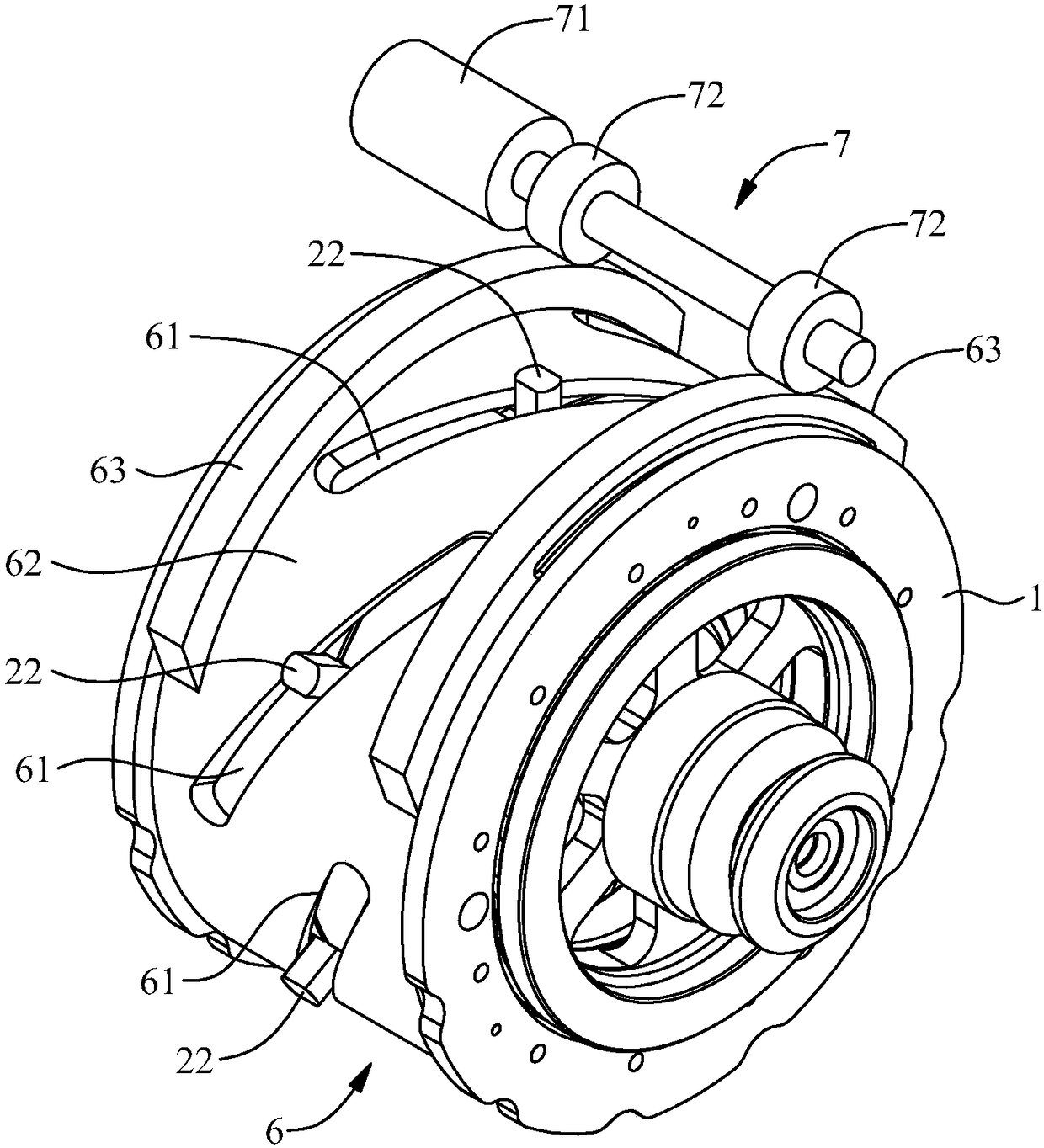

[0092] The continuously variable speed control system of the rolling vehicle according to the embodiment of the present invention will be further described below with reference to the accompanying drawings.

[0093] First, please refer to Figure 1 to Figure 14 , as shown in the figure, the present invention provides a continuously variable speed control system for rolling vehicles, which includes an electronic control device 9, which is electrically connected to a variable speed drive unit 7, and the variable speed drive unit 7 is connected to a belt type continuously variable transmission 8 or a rolling ball type CVT. Wherein, the driving belt type continuously variable transmission 8 can have a driving wheel 81, a driven wheel 82 and a driving belt 83, the driving belt 83 can be a belt or a metal belt, the cross section of the driving belt 83 can be trapezoidal, and the driving belt 83 is movably sleeved on the V-shaped shape of the driving wheel 81. Groove and the V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com