Thick, large and high silicon molybdenum casting of nodular cast iron and preparation technology of casting

A nodular cast iron, preparation process technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve high temperature resistance, high temperature creep resistance, poor oxidation resistance, inability to withstand engine high temperature, low strength and rigidity And other problems, to achieve the effect of uniform hardness, stable structure, strength and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

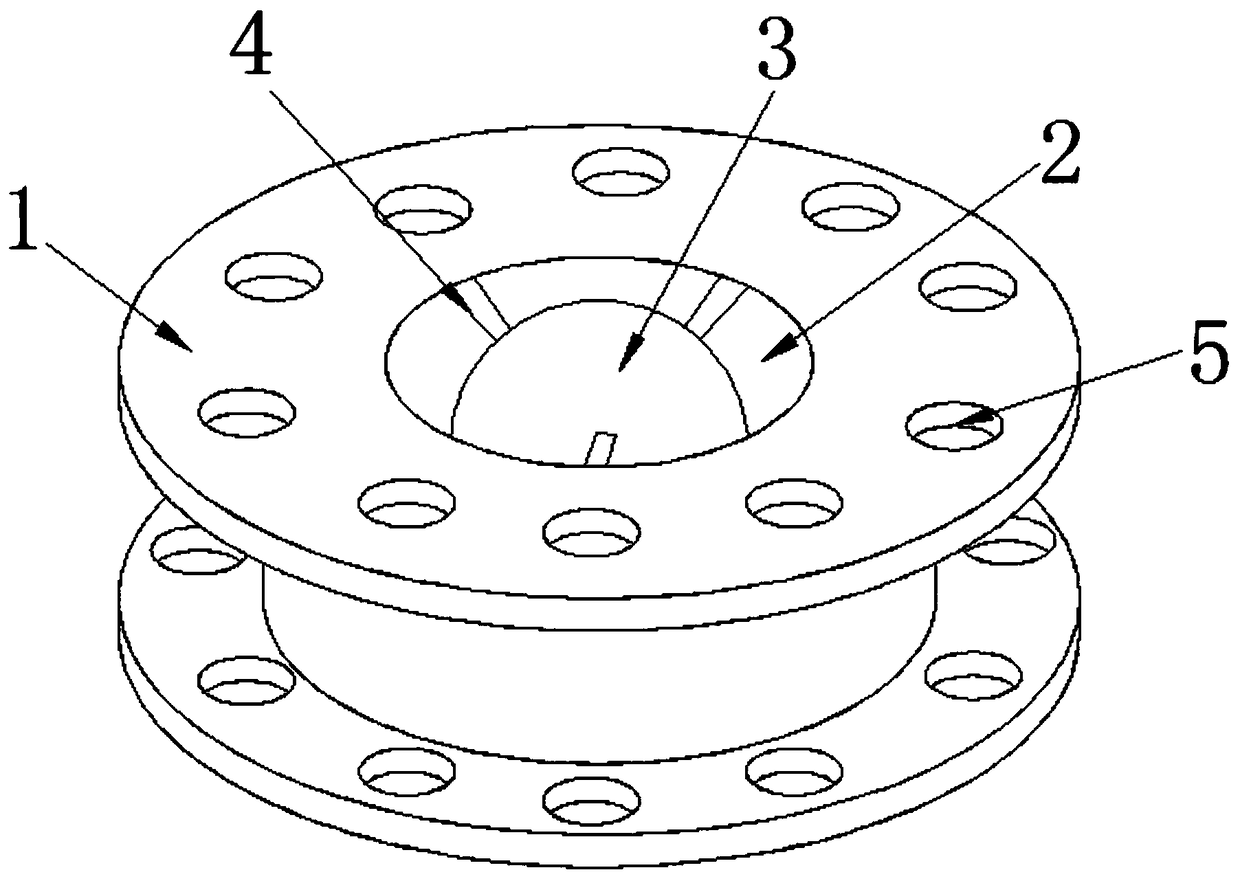

[0026] see Figure 1-4 , the present invention provides a technical solution: a thick high-silicon-molybdenum ductile iron, including an outer casting 1, a channel 2 is opened inside the outer casting 1, an inner casting 3 is arranged inside the channel 2, and the inner casting 3 is passed through a reinforcing rib 4 is fixedly connected with the outer casting 1.

[0027] Further, the outer casting 1 is in an I-shape, and several installation holes 5 are symmetrically opened on the upper surface and the lower surface of the outer casting 1 .

[0028] Further, the number of reinforcing ribs 4 is three, and the three reinforcing ribs 4 are distributed in an annular array on the outer surface of the inner casting 3 , and the ends of the three reinforcing ribs 4 away from the inner casting 3 are all fixedly connected to the outer casting 1 .

[0029] Further, the outer casting 1, the inner casting 3 and the rib 4 are integrally formed by pouring.

[0030] Further, the casting of...

Embodiment 2

[0038] see Figure 1-4 , the present invention provides a technical solution: a thick high-silicon-molybdenum ductile iron, including an outer casting 1, a channel 2 is opened inside the outer casting 1, an inner casting 3 is arranged inside the channel 2, and the inner casting 3 is passed through a reinforcing rib 4 is fixedly connected with the outer casting 1.

[0039] Further, the outer casting 1 is in an I-shape, and several installation holes 5 are symmetrically opened on the upper surface and the lower surface of the outer casting 1 .

[0040] Further, the number of reinforcing ribs 4 is three, and the three reinforcing ribs 4 are distributed in an annular array on the outer surface of the inner casting 3 , and the ends of the three reinforcing ribs 4 away from the inner casting 3 are all fixedly connected to the outer casting 1 .

[0041] Further, the outer casting 1, the inner casting 3 and the rib 4 are integrally formed by pouring.

[0042] Further, the casting of...

Embodiment 3

[0050] see Figure 1-4 , the present invention provides a technical solution: a thick high-silicon-molybdenum ductile iron, including an outer casting 1, a channel 2 is opened inside the outer casting 1, an inner casting 3 is arranged inside the channel 2, and the inner casting 3 is passed through a reinforcing rib 4 is fixedly connected with the outer casting 1.

[0051] Further, the outer casting 1 is in an I-shape, and several installation holes 5 are symmetrically opened on the upper surface and the lower surface of the outer casting 1 .

[0052] Further, the number of reinforcing ribs 4 is three, and the three reinforcing ribs 4 are distributed in an annular array on the outer surface of the inner casting 3 , and the ends of the three reinforcing ribs 4 away from the inner casting 3 are all fixedly connected to the outer casting 1 .

[0053] Further, the outer casting 1, the inner casting 3 and the rib 4 are integrally formed by pouring.

[0054] Further, the casting of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com