A fully supported fracturing method for fractured reservoirs

A fracturing and reservoir technology, which is applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as the inability to successfully complete the construction, the limited volume of fracture stimulation, and restrict the degree of reservoir production, and achieve important economic benefits. Economic and social benefits, the effect of increasing the fracturing stimulation volume, and improving the fracturing stimulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

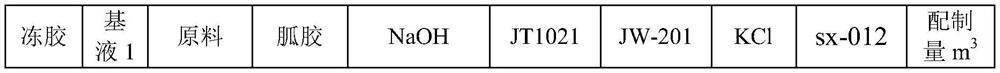

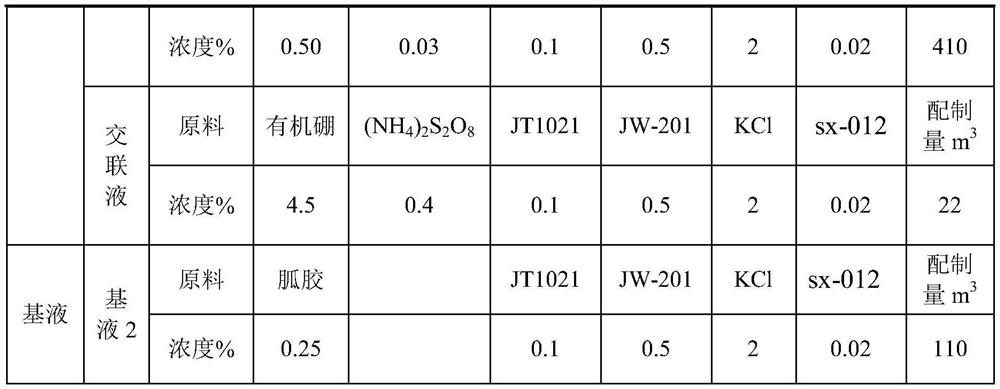

[0027] A fully supported fracturing method for fractured reservoirs, aimed at the downhole of Lao 2 Inclined-2-11 3 3 Construction design liquid volume 332.4m 3 , design displacement 2.5-3.5m 3 / min, the specific fracturing process includes the following steps:

[0028] 1) For the fracturing pre-fluid stage, 2.5m 3 Gel and 0.25% base fluid are injected alternately, first the gel is pumped with small particle size proppant according to 8% sand ratio, and then 0.25% base fluid is used to carry small particle size proppant according to 5% sand ratio The proppant is pumped according to the jelly and 0.25% base fluid respectively carrying 8% and 5% small particle size proppant to carry out three slugs, and then the prefluid supporting natural fracture process is completed;

[0029] 2) In the sand-carrying fluid stage of fracturing, use 3.5m of jelly 3 / min displacement starts from 10% sand ratio to carry medium-sized proppant, and then gradually increases 2% sand ratio to carr...

Embodiment 2

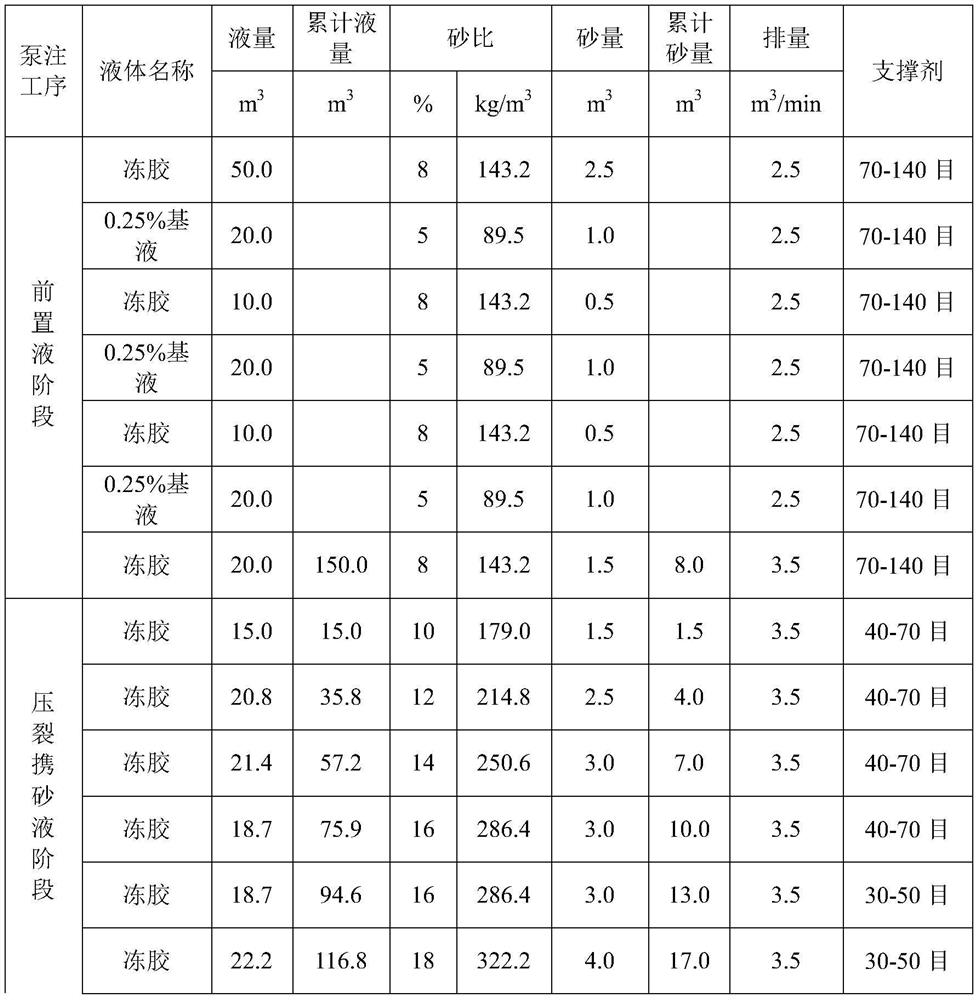

[0041] A fully supported fracturing method for fractured reservoirs, aimed at the old 2-2-9 underground well 1 3 Construction design liquid volume 249.6m3 , design displacement 2.5-3.5m 3 / min, using the fracturing fluid system described in Example 1, the specific fracturing process includes the following steps as shown in Table 3:

[0042] Table 3 Pumping program of the old 2-2-9 well

[0043]

[0044]

[0045] The well depth of this example is 2428.2m, the temperature is 97°C; the viscosity of the prepared jelly is 200mpa.s, and the viscosity of the base fluid is 15mpa.s.

[0046] After adopting the full support fracturing technology described in this embodiment, the daily production increase increases from 0.5t to 4.2t.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com