Annealing furnace shell modular installation method

An installation method and technology of annealing furnaces, which are applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of heavy assembling and welding of annealing furnace shells, long assembly periods, and difficulty in ensuring dimensional accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

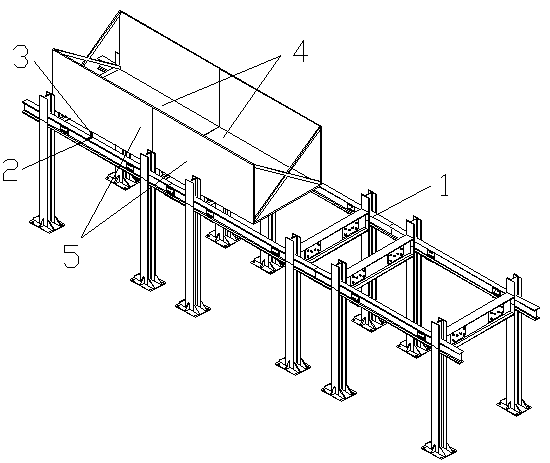

[0012] Example figure 1 As shown, the annealing furnace shell modular installation method of the present invention comprises the following steps:

[0013] Step 1. Set up a steel structure platform 1 for supporting the furnace shell of the annealing furnace, and mark the positioning line 2 of the bottom plate of the furnace shell and the reference line 3 of the wall plate of the furnace shell on the installation position of the furnace shell on the top surface of the steel structure platform 1;

[0014] Step 2, modularize the annealing furnace shell, including a number of furnace shell bottom plate modules 4 and furnace shell wall plate modules 5 connected in sequence and mark the installation serial number;

[0015] Step 3. Hoist the furnace shell bottom plate module 4 of the previous serial number to the steel structure platform 1 and adjust the positioning according to the positioning line 2, hoist the furnace shell wall plate module 5 corresponding to the furnace shell bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com