Rice hull powder modified recycled polyvinyl chloride composition and preparation method thereof

A technology of polyvinyl chloride and rice husk powder is applied in the field of modified and regenerated polyvinyl chloride composition of rice husk powder and its preparation, which can solve the problems of large difference in bulk density, difficulty in mixing uniformly, poor mechanical properties, etc. Excellent performance, good mechanical properties, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

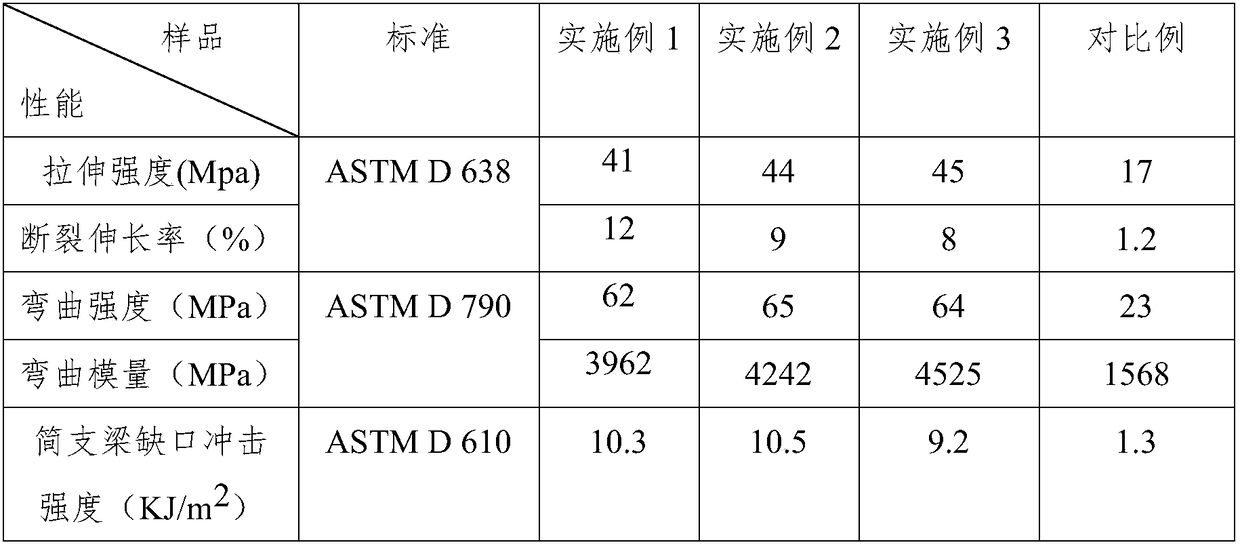

Examples

Embodiment 1

[0024] The rice husk powder modified regenerated polyvinyl chloride composition in this example is made from the following raw materials in parts by weight: 100 parts of regenerated polyvinyl chloride, 3 parts of stearic acid amide, 15 parts of rice husk powder, 2 parts of ethylene-acrylate copolymer material, 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168; wherein the particle size of rice husk powder is 150 mesh;

[0025] The preparation method of the rice husk powder modified regenerated polyvinyl chloride composition of the present embodiment comprises the following steps:

[0026] S1. Weigh the regenerated polyvinyl chloride and stearic acid amide in parts by weight, add them to the blender, the speed of the blender is 300r / min, and mix for 2min;

[0027] S2, take the rice husk powder of weight part, join in the mixer of step S1, the speed of mixer is 300r / min, mix 2min, then add the compatibilizer of weight part, antioxidant, mix and stir 2min, obtain mixed m...

Embodiment 2

[0030] The rice husk powder modified regenerated polyvinyl chloride composition in this example is made of the following raw materials in parts by weight: 100 parts of regenerated polyvinyl chloride, 2.5 parts of stearic acid amide, 20 parts of rice husk powder, 2.5 parts of ethylene-acrylate copolymer 0.1 part of antioxidant 1010, 0.2 part of antioxidant 168, 0.3 part of antioxidant DSTDP; wherein the particle size of rice husk powder is 200 mesh;

[0031] The preparation method of the rice husk powder modified regenerated polyvinyl chloride composition of the present embodiment comprises the following steps:

[0032] S1. Weigh the regenerated polyvinyl chloride and stearic acid amide in parts by weight, add them to the blender, the speed of the blender is 400r / min, and mix for 5min;

[0033] S2, take the rice husk powder of weight part, join in the mixer of step S1, the speed of mixer is 350r / min, mix 5min, then add the compatibilizer of weight part, antioxidant, mix and sti...

Embodiment 3

[0036] The rice husk powder modified regenerated polyvinyl chloride composition in this example is made of the following raw materials in parts by weight: 100 parts of regenerated polyvinyl chloride, 6 parts of stearic acid amide, 35 parts of rice husk powder 150 mesh, 3 parts of ethylene-acrylic acid Ester copolymer, 0.2 part of antioxidant 1010, 0.3 part of antioxidant 168, 0.3 part of antioxidant DSTDP; wherein the particle size of rice husk powder is 200 mesh;

[0037] The preparation method of the rice husk powder modified regenerated polyvinyl chloride composition of the present embodiment comprises the following steps:

[0038] S1. Weigh the regenerated polyvinyl chloride and stearic acid amide in parts by weight, add them to the blender, the speed of the blender is 400r / min, and mix for 5min;

[0039] S2, take the rice husk powder of weight part, join in the mixer of step S1, the speed of mixer is 400r / min, mix 5min, then add the compatibilizer of weight part, antioxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com