Preparation method of ferric phosphate with high iron/ phosphorus ratio

A technology of iron phosphate and high iron, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of unfavorable industrial production, complicated operation steps, high production cost, etc., and achieve uniform and controllable particle size and uniform distribution of solution , the effect of reducing the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, achieved objectives and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments.

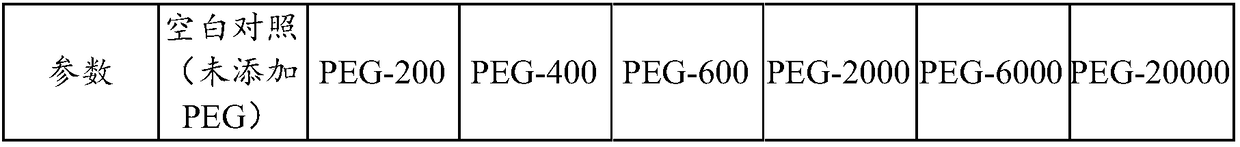

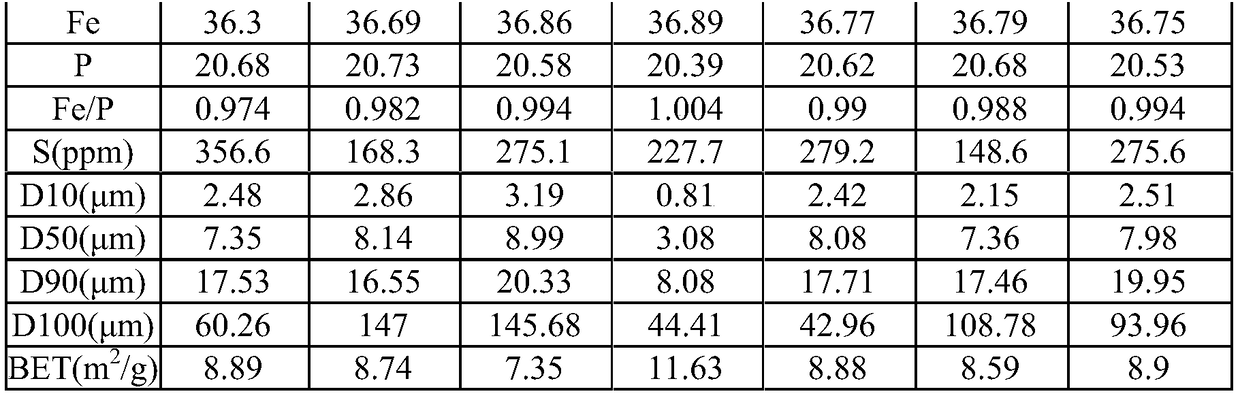

[0022] The most critical idea of the present invention is: the present invention scheme first joins polyethylene glycol and phosphoric acid into the ferrous salt solution, then adds phosphate and hydrogen peroxide under stirring to oxidize the ferrous salt into iron salt and combines with phosphate to form phosphoric acid Iron and polyethylene glycol make the distribution of the solution more uniform and reduce the existence of free iron ions. The iron-phosphorus ratio of the prepared iron phosphate can reach more than 0.98, the particle size is uniform and controllable, and the impurity content is low.

[0023] A preparation method for high iron-phosphorus ratio iron phosphate, comprising the following steps:

[0024] S1, configuring ferrous salt solution, adding phosphoric acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com