Sensitive efficient mobile small scissor type lifter

A kind of lift, high-efficiency technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of operational safety hazards, low sensitivity, and affecting the performance of small scissor lifts, etc., to achieve smooth operation, reasonable layout, and best convenience Effects on sex and fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to more clearly illustrate the technical solutions in the embodiments of the present application or in the prior art, the following briefly introduces the drawings that are required in the description of the embodiments or the prior art.

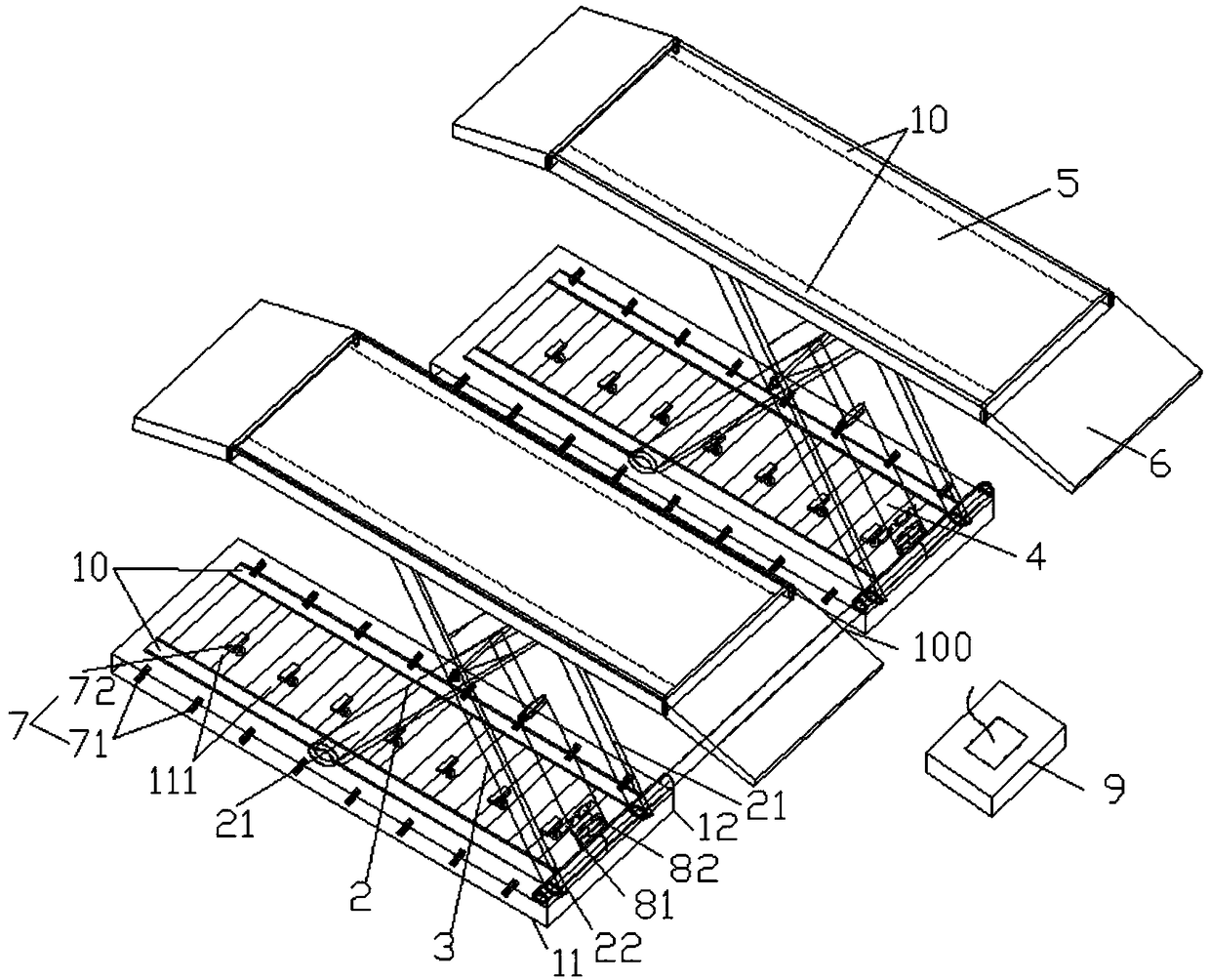

[0023] Such as figure 1 , a sensitive and efficient mobile small scissor lift, including:

[0024] The two bases 1 are in the shape of a rectangular plate, distributed in parallel and at intervals. Each base 1 has a long side 11 and a short side 12. A slideway 10 is arranged inside the long side 11 on both sides, and a main hinge shaft 100 is set on one short side 12. The hinge shaft 100 runs through the short sides 12 of the two bases 1; each base 1 is provided with a hinged inner scissor arm 2 and an outer scissor arm 3;

[0025] The edge and the middle of the base 1 are provided with a sliding mechanism 7 at the bottom; several support columns 111 are arranged in the middle of the base 1, and a sliding mechanism 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com