A miniature trolley used for installation and inspection of asphalt cargo tank adjustment pads

A technology for adjusting pads and miniature trolleys, which is applied in ship construction, ship design, ship parts, etc., can solve the problems of wasting valuable time of the ship owner, affecting the cargo tank piping system, the progress of oil stringing, and affecting the installation cycle of the cargo tank, etc. To achieve the effect of ensuring the original accuracy and detection accuracy, shortening the inspection time, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

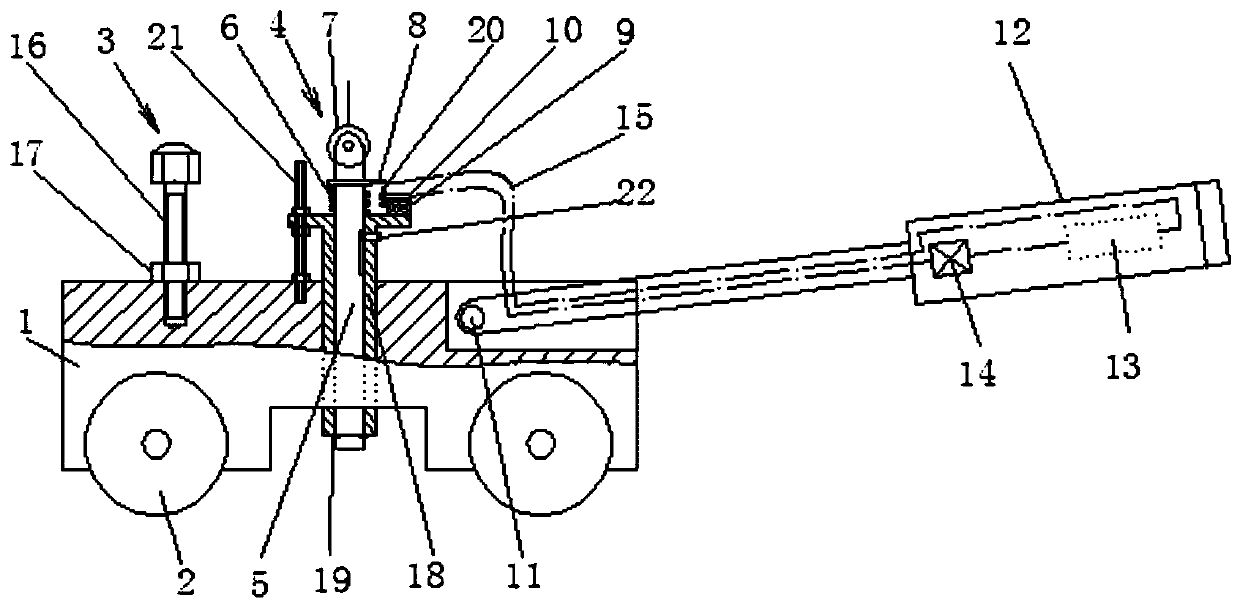

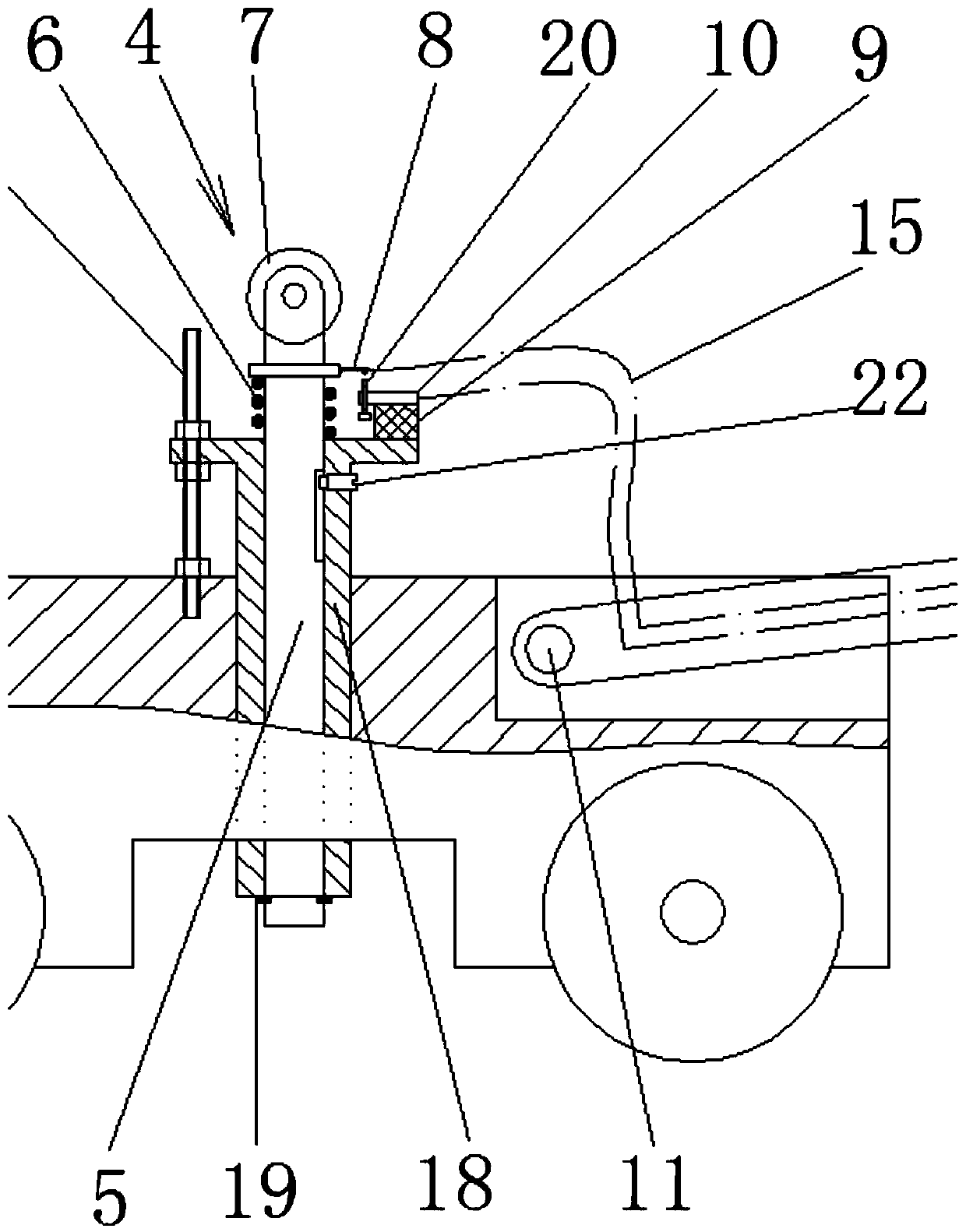

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

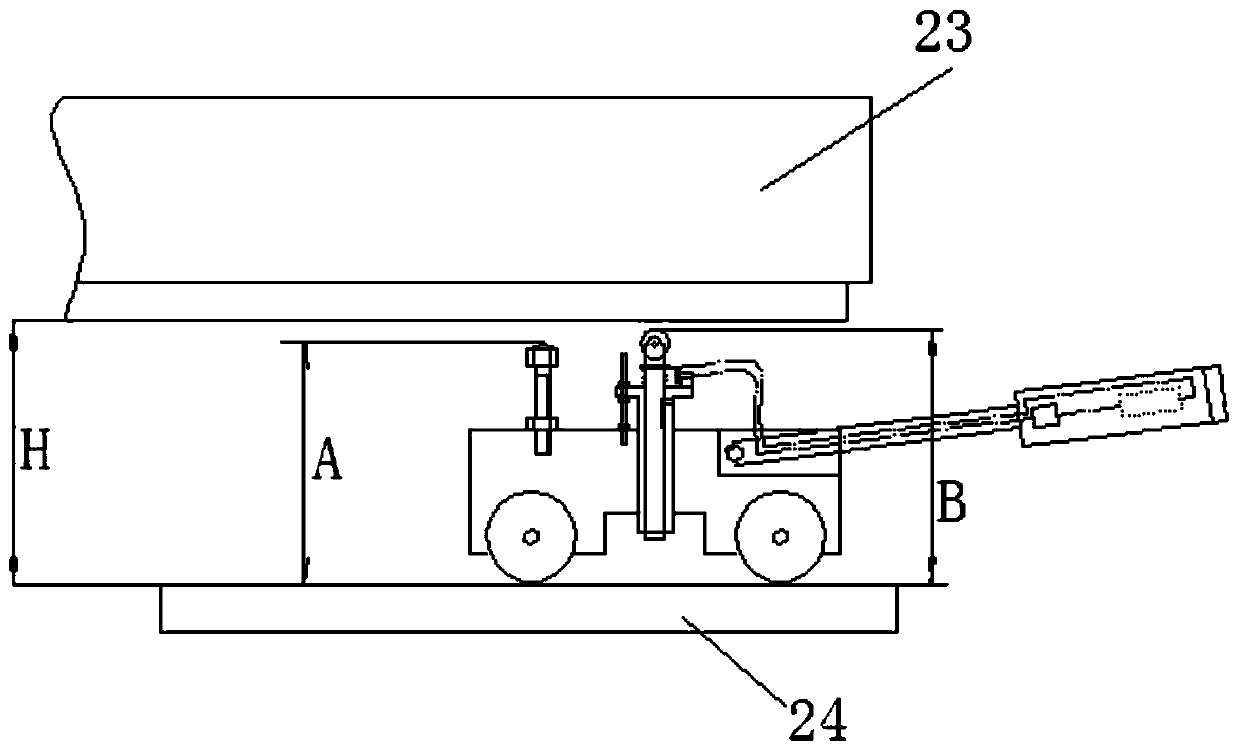

[0033] Such as Figures 1 to 3 Shown is an embodiment of a miniature trolley used for the installation and inspection of asphalt cargo tank adjustment pads of the present invention, including a car body 1, and a certain number of rigid wheels 2 are arranged on the lower part of the car body 1. The upper part of the body 1 is sequentially provided with a through gauge 3 and a floating stop gauge 4 for detecting the height limit position between the bottom plane of the cargo tank 23 before falling into the tank and the adjustment pad 24 according to the direction from front to back. The height of the top of the tank is equal to the minimum value of the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com