Dedusting workbench for metal polishing

A workbench and workbench base technology, applied in the fields of environmental protection equipment and dust removal equipment, can solve problems affecting grinding accuracy, damage, inconvenience, etc., and achieve the effects of improving absorption effect, work efficiency, and absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

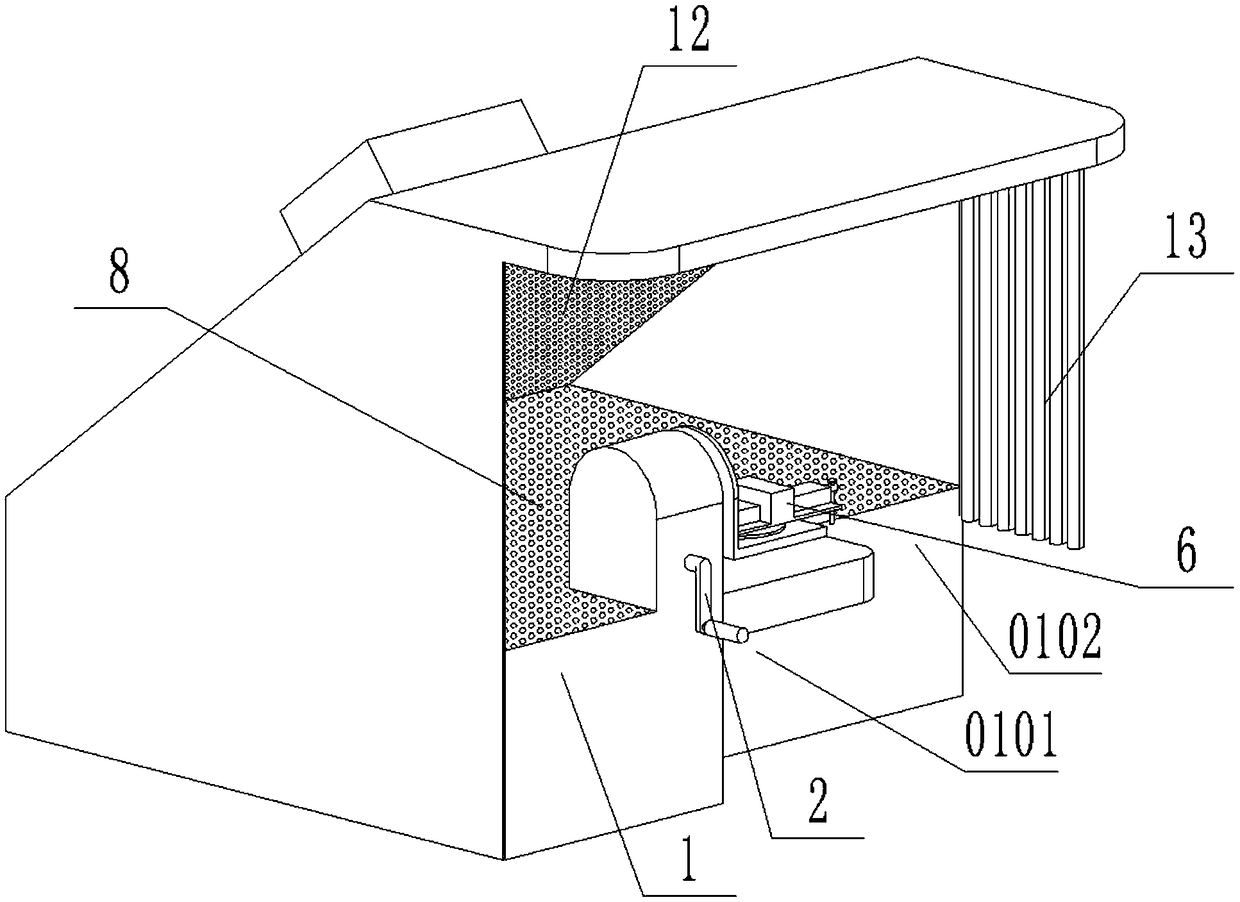

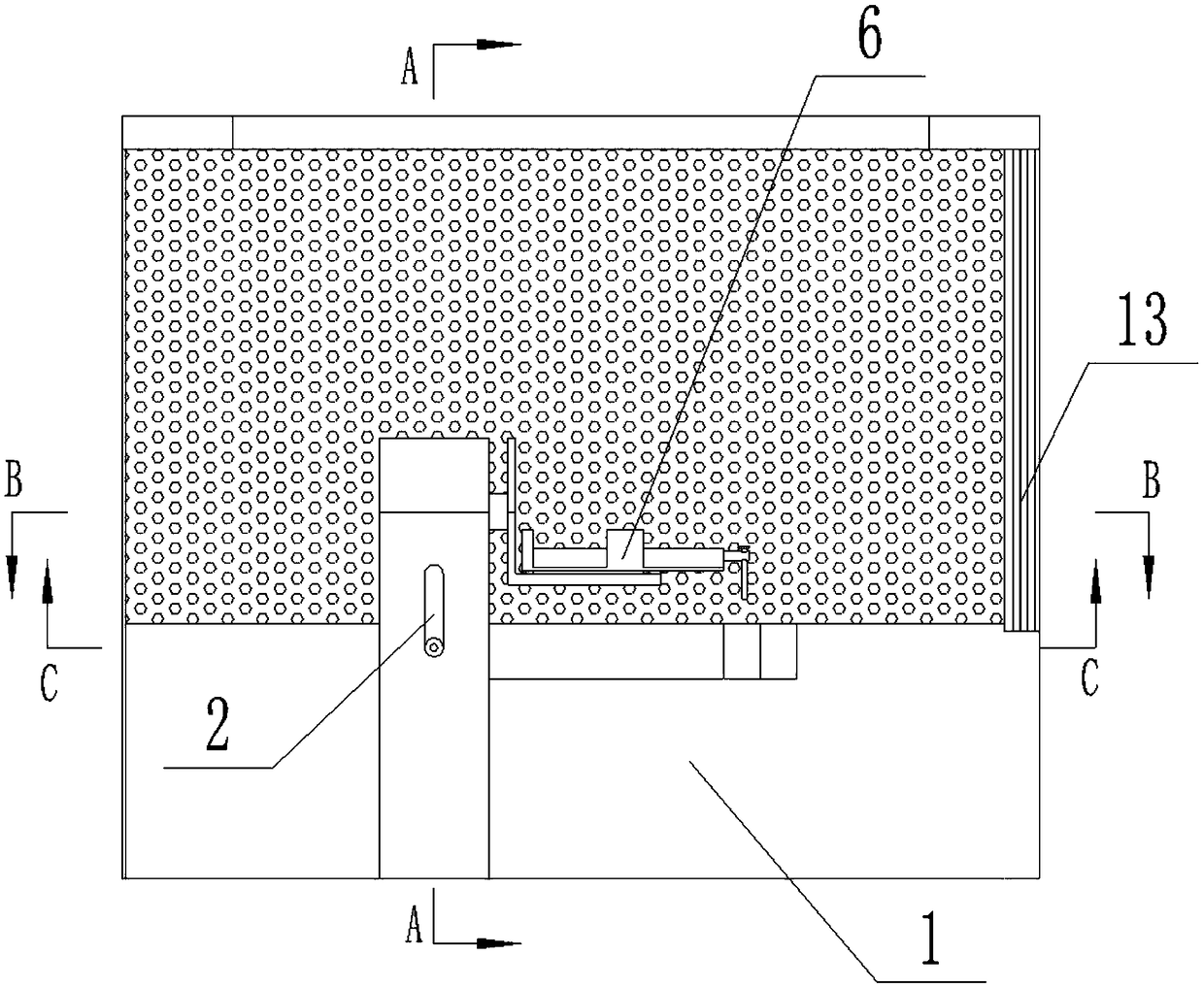

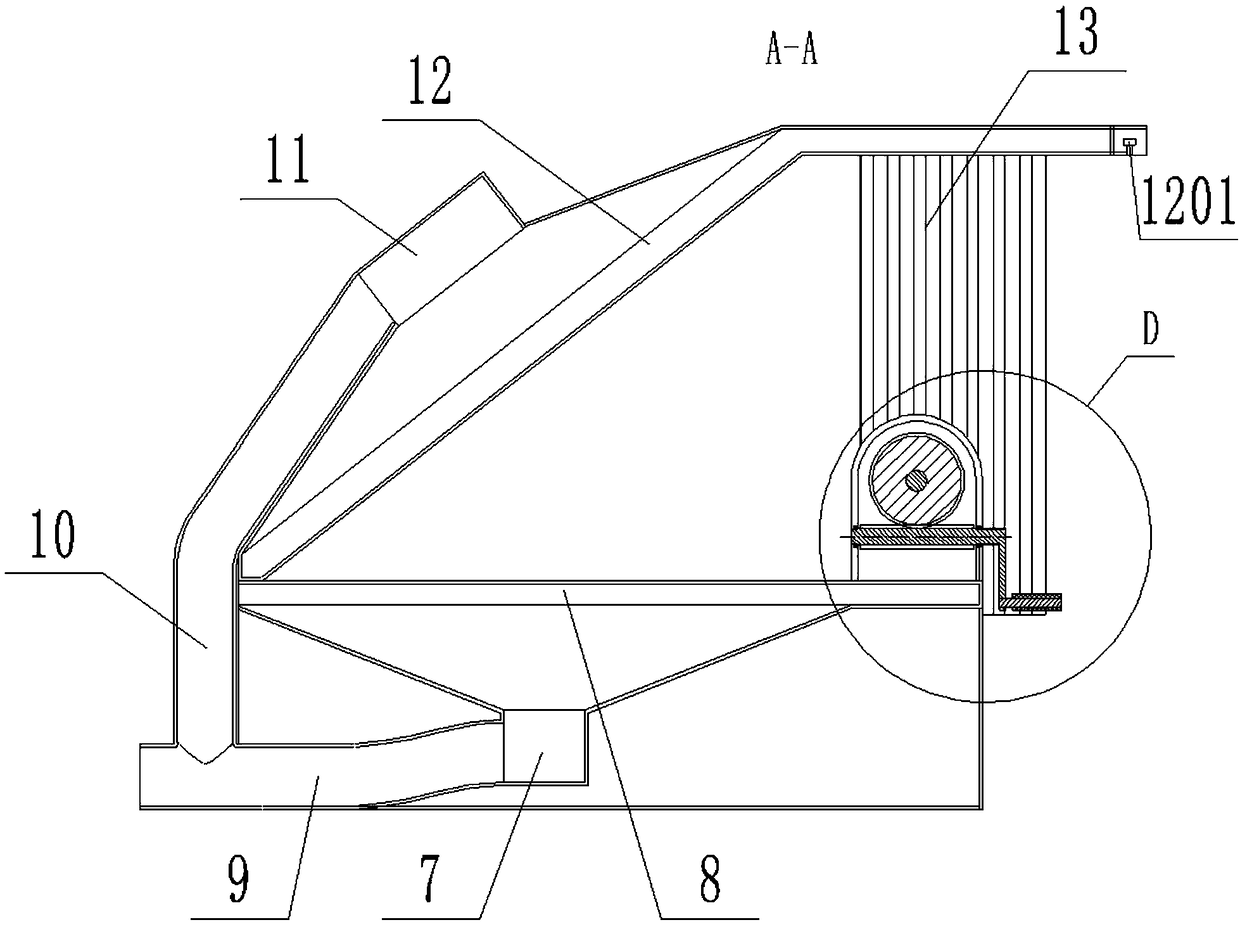

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a dust removal workbench for metal grinding, including: a workbench base 1, a bottom movable space 0101, a corner space 0102, a handle 2, a worm 3, a worm wheel 4, a steering table 5, a vise 6, a bottom fan 7, Working surface vacuum board 8, bottom air duct 9, top air duct 10, top fan 11, top vacuum board 12, slideway 1201, shielding curtain 13 and pulley 14; workbench base 1 front end surface is axially connected with a group Handle 2; a set of worms 3 is coaxially fixedly connected to the rear end of the handle 2; a set of steering table 5 is axially connected to the upper part of the worktable base 1; a set of vise 6 is fixedly connected to the steering table 5; the inner bottom surface of the workbench base 1 is fixed A set of bottom fans 7 are connected; the top of the bottom fans 7 is fixedly connected with a set of working surface dust collection boards 8; the left side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com