A powder building material mixing device

A technology of mixing device and building material powder, which is applied in chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem of small mixing range, limitation, building material powder No problems such as stirring can be obtained, and the effects of increasing the stirring range, increasing the service life and improving work efficiency are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

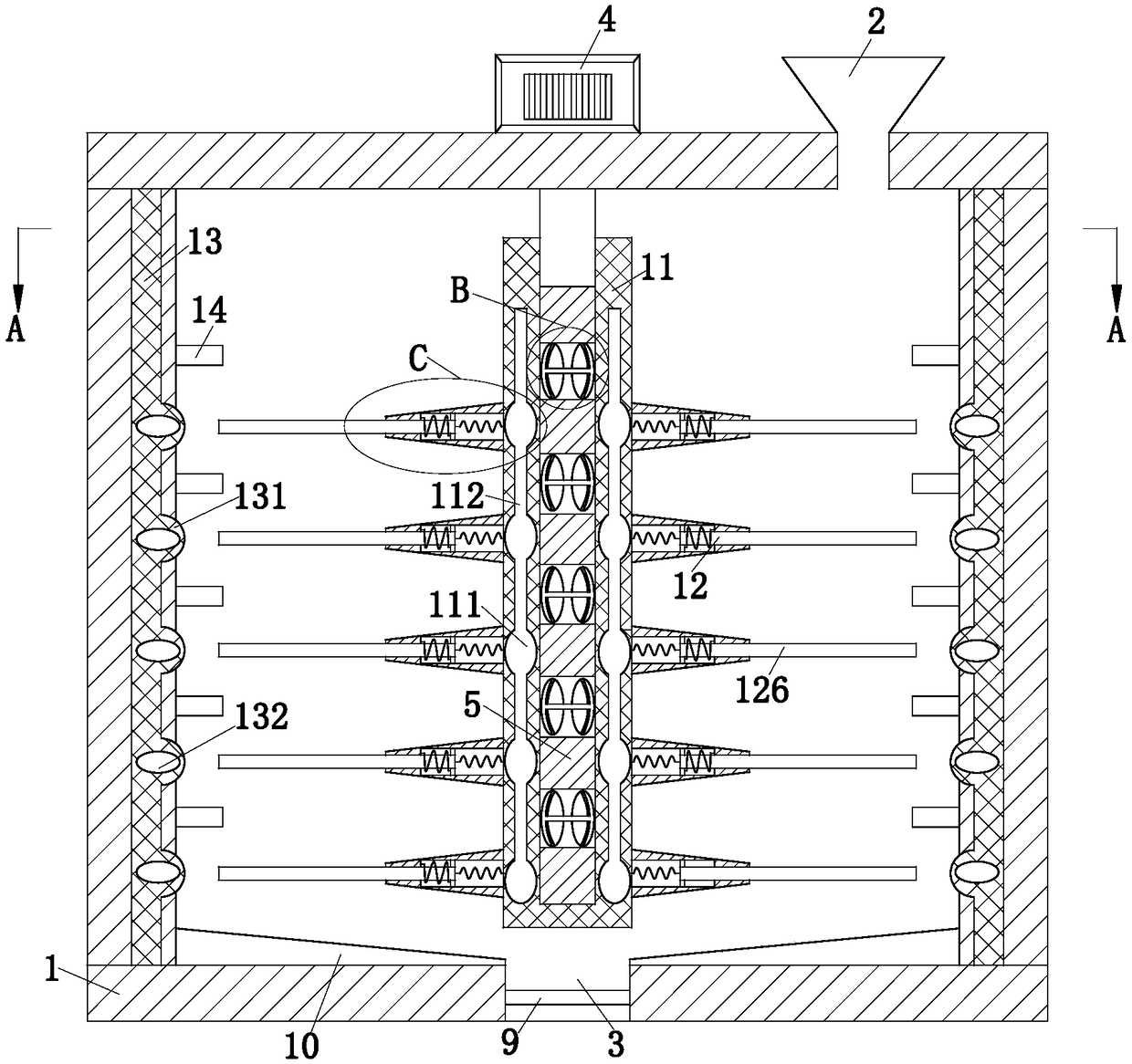

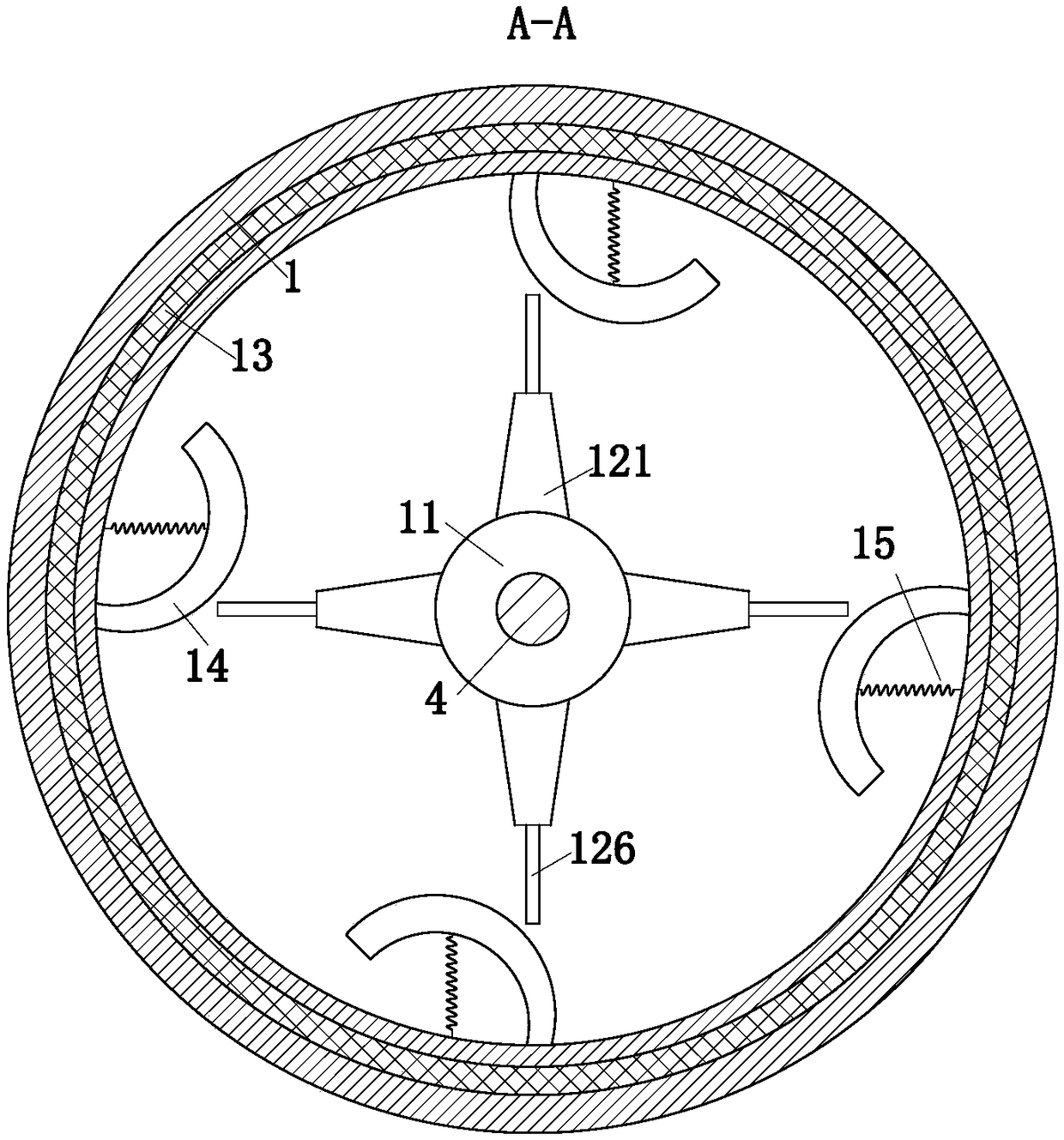

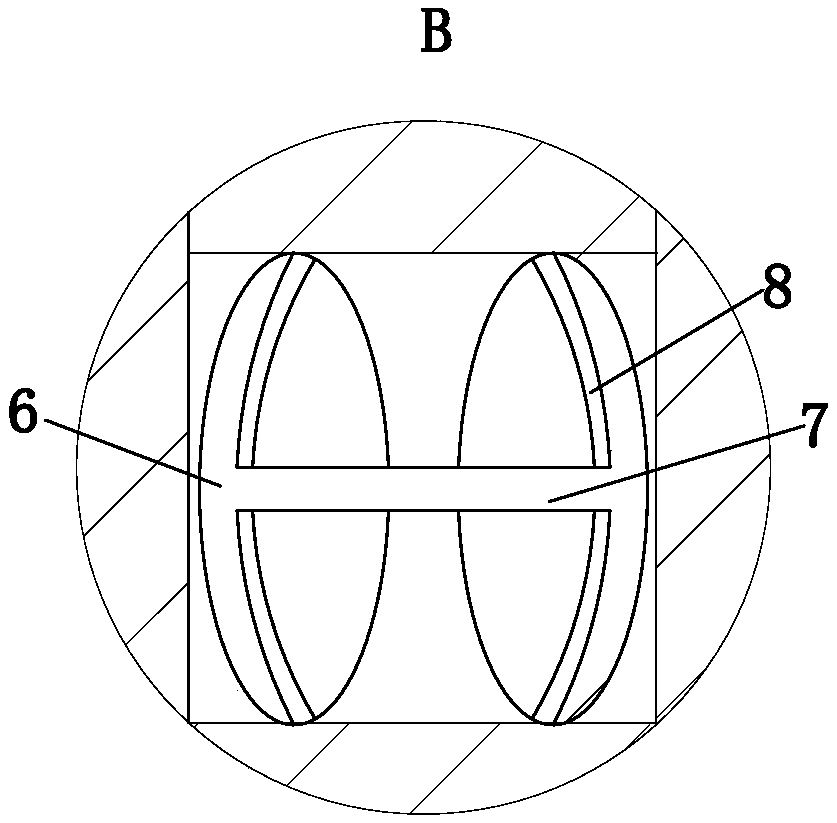

[0031] As an embodiment of the present invention, the outer side of the U-shaped rubber ring 11 is evenly distributed with a stirring unit 12, and the stirring unit 12 is used to stir the building material powder; the stirring unit 12 includes an oblique groove 121, a square groove 122, No. 1 spring 123, No. 2 spring 124, piston 125 and stirring rod 126; the inclined groove 121 is used to prevent building material powder from staying on the surface of the stirring unit 12; the square groove 122 is set inside the inclined groove 121; the One end of the stirring rod 126 extends into the square groove 122 and is socketed with the piston 125; the piston 125 is in contact with the inner wall of the square groove 122; The side wall of the square groove 122 is connected; the No. 2 spring 124 is sleeved on the surface of the stirring rod 126, and one end of the No. 2 spring 124 is affixed to the side of the piston 125 away from the No. 1 spring 123, and the other end of the No. 2 sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com