A kind of ammonia drying device and drying method based on temperature swing adsorption

A temperature swing adsorption and drying device technology, applied in chemical instruments and methods, separation methods, ammonia compounds, etc., can solve problems such as fluctuations in water content and inability to meet quality requirements, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The ammonia gas purification unit for a certain strip steel production unit purchases raw material liquid ammonia as a superior product with an impurity content of less than 0.1%. The intermediate product ammonia gas produced after gasification by a water-bath gasifier and distillation with 7°C cooling water has a water content of Usually at the 80-160ppm level.

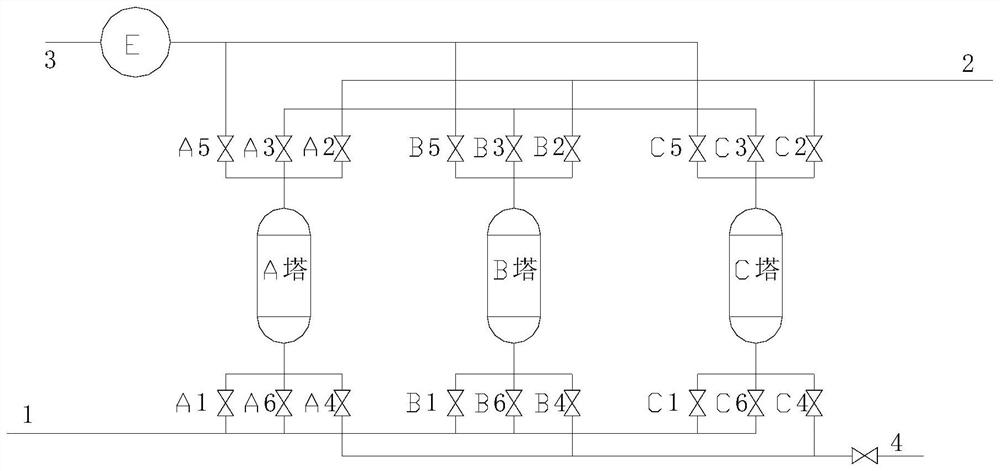

[0050] The ammonia gas inlet port (1) is connected with the intermediate product ammonia gas, and the product ammonia gas pressure is 0.2-0.4MPa. The ammonia gas outlet port (2) is connected to the ammonia gas user after being connected to the product ammonia gas buffer tank. The regeneration gas inlet port (3) is connected to the factory nitrogen pipeline, and the pressure of the nitrogen pipeline network is 0.2-0.7MPa. The tail gas exhaust port (4) is connected with the ammonia release tank of the factory tail gas treatment device, and the working pressure of the ammonia release tank is about 10kPa. The ad...

Embodiment 2

[0055] The raw material ammonia is a first-class product, and its impurity content is less than 0.2%. The water content of the intermediate product ammonia gas after gasification and distillation is usually in the range of 150-360ppm, and the water content fluctuates even more during a period of time after each liquid ammonia storage tank is filled.

[0056] Others are the same as embodiment 1.

[0057] The device and method shown in the examples are used to process the intermediate product ammonia, and the American Tiger Optics HALOLP water analyzer is used to conduct online detection of the ammonia water content of the product. The ammonia water content of the product is stably controlled below 5ppm, which fully meets the needs of ammonia users. Requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com