A Design Method of Tray Structure for Eliminating Gas Phase Drift Flow

A technology of structural design and tray, applied in the field of chemical vapor-liquid mass transfer separation equipment, can solve the problems of pouring at the entrance of tray, reduction of tray efficiency, liquid flooding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0111] The design gas phase mass flow rate is 15000kg / hr, and the gas phase density is 2.5kg / m 3 , the mass flow rate of the liquid phase is 40000kg / hr, and the density of the liquid phase is 880kg / m 3 , the surface tension is 10N / m, and the viscosity is 1mPa·s. The mass transfer tray type is selected as a sieve tray column. Through the preliminary design, the structural parameters of the tray type are shown in Table 1:

[0112] Table 1 Design parameters of mass transfer tray structure

[0113]

[0114] The parameters calculated by formulas (1) to (9) are shown in Table 2:

[0115]Table 2 Calculation results of parameters related to liquid level gradient in mass transfer trays

[0116]

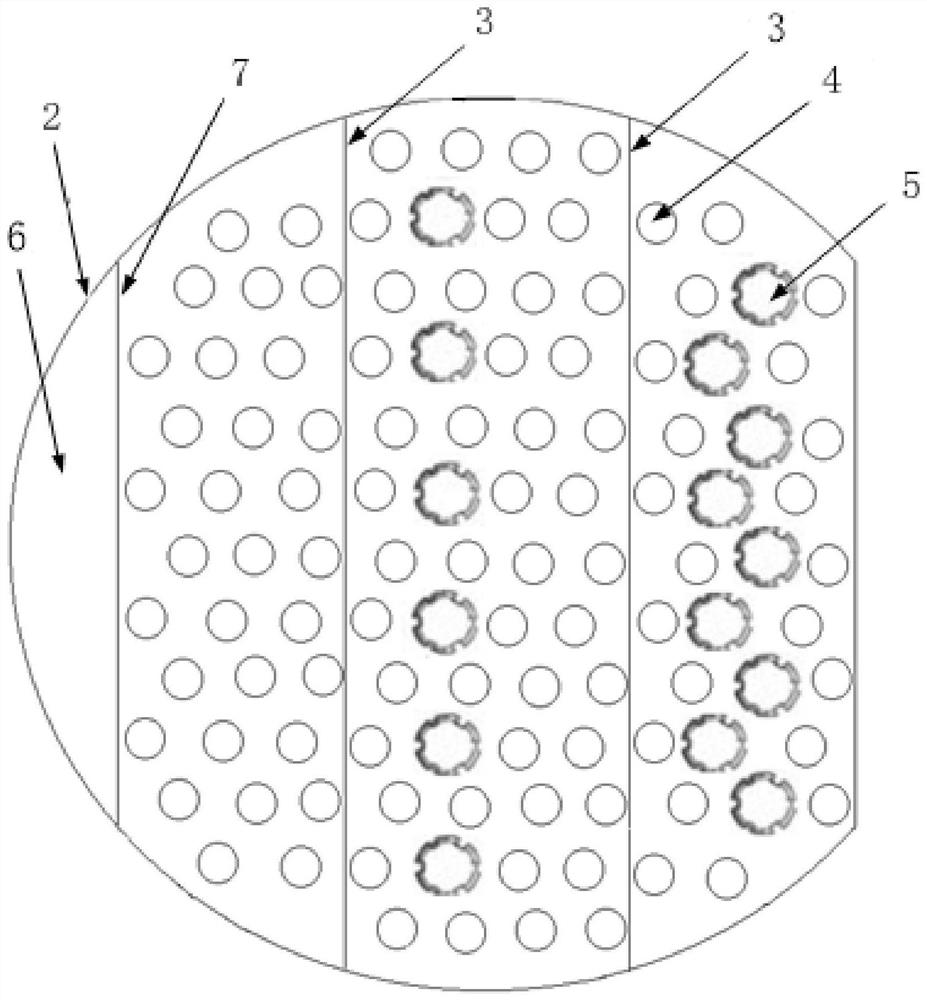

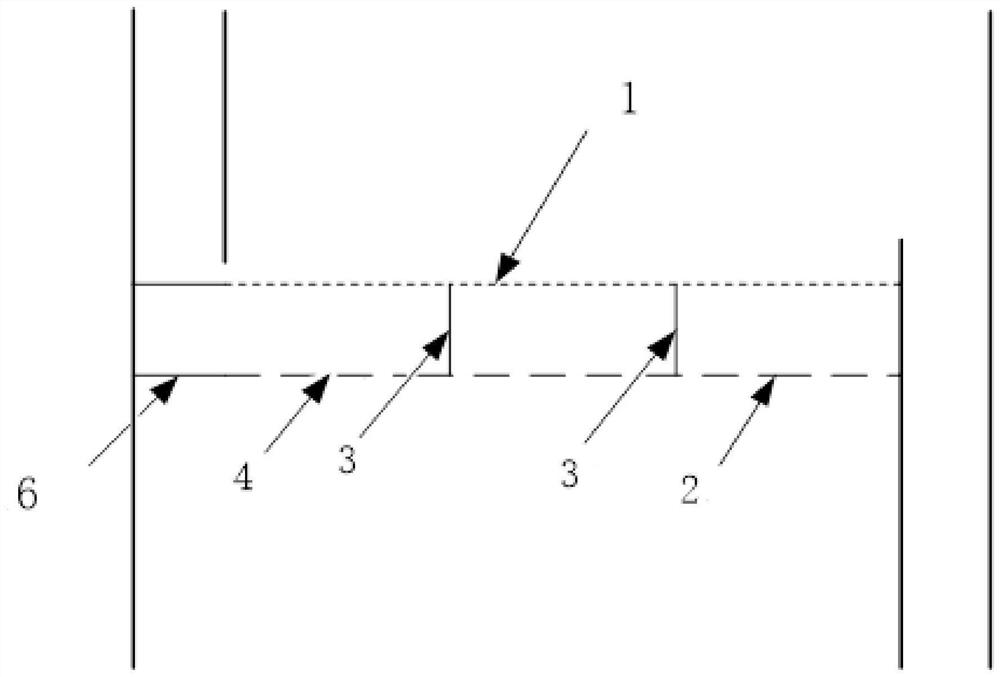

[0117] Divide the gas phase distribution plate into five zones, the length of each zone is 200mm, and take the gas phase distribution plate aperture ratio ratio coefficient of 1.4 (the gas phase distribution plate aperture ratio is 17.85%), then the vapor obtained by formula (15) is c...

Embodiment 2

[0124] The designed gas mass flow rate is 60000kg / hr and the gas phase density is 2.5kg / m 3 , the liquid mass flow rate is 70000kg / hr, and the liquid phase density is 880kg / m 3 , the surface tension is 10N / m, and the viscosity is 1mPa·s. The type of mass transfer tray is selected as sieve tray. Through preliminary design, the structural parameters of this tray are shown in Table 5:

[0125] Table 5 Design parameters of mass transfer tray structure

[0126]

[0127] The parameters calculated by formulas (1) to (9) are shown in Table 6:

[0128] Table 6 Calculation results of parameters related to liquid level gradient of mass transfer tray

[0129]

[0130] Divide the gas phase distribution plate into four zones, the length of each zone is 400mm, and take the gas phase distribution plate aperture ratio ratio coefficient of 1.4 (the gas phase distribution plate aperture ratio is 20.31%), then the gas phase calculated by formula (15) is obtained. The apparent hole veloc...

Embodiment 3

[0137] The designed gas mass flow rate is 60000kg / hr and the gas phase density is 2.5kg / m 3 , the liquid mass flow rate is 70000kg / hr, and the liquid phase density is 880kg / m 3 , the surface tension is 10N / m, and the viscosity is 1mPa·s. The type of mass transfer tray is selected as sieve tray. Through preliminary design, the structural parameters of this tray are shown in Table 9:

[0138] Table 9 Design parameters of mass transfer tray structure

[0139]

[0140] The parameters calculated by formulas (1) to (9) are shown in Table 10:

[0141] Table 10 Calculation results of parameters related to liquid level gradient in mass transfer trays

[0142]

[0143] Divide the gas distribution plate into 2 areas, the length of each area is 800mm, and take the gas phase distribution plate aperture ratio ratio coefficient of 1.4 (the gas phase distribution plate aperture ratio is 20.31%), then the gas phase calculated by formula (15) is obtained. The apparent hole velocity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com