Modular wood-panel assembled furniture based on mass customization standardized production

A modular, large-scale technology, applied in home appliances, furniture parts, chests of drawers, etc., can solve the problems of narrow choice of consumers and can not meet the individual needs of customers, and achieve the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

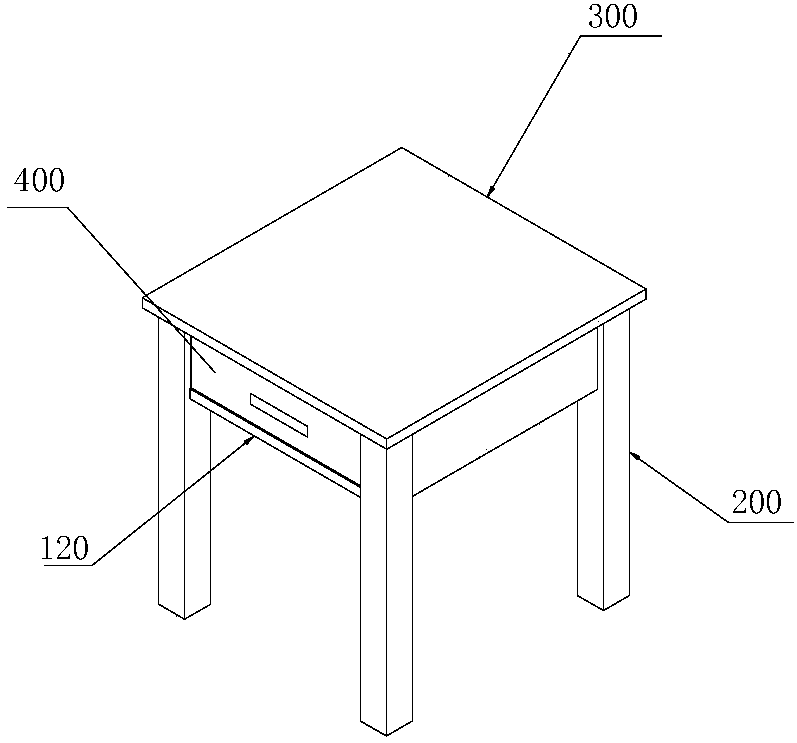

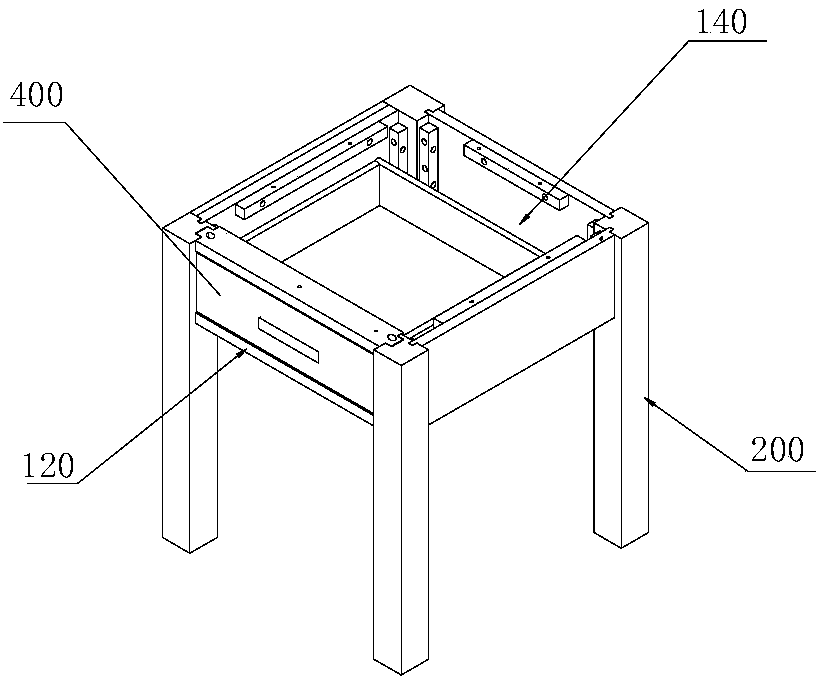

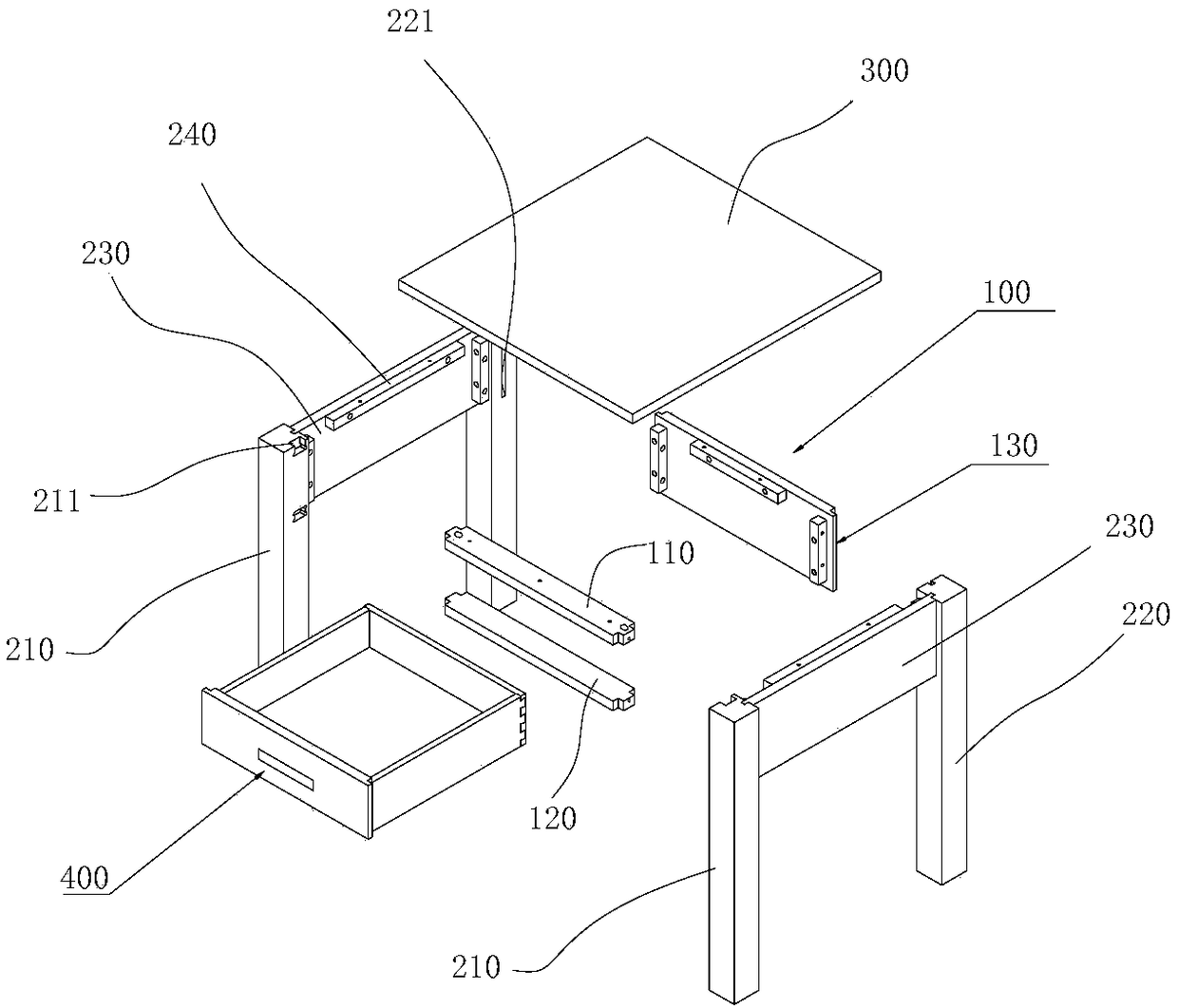

[0056] Example 1, see Figure 1 to Figure 8 , a corner table based on mass customization and standardized production, including a main frame 100, two side panel module assemblies 200 with the same structure and a style panel 300;

[0057] The side panel module assembly 200 is installed on the left and right sides of the main frame 100; the style panel is located on the upper surface of the main frame, and is connected with the side panel module assembly 200 and the main frame 100;

[0058] The main body frame 100 includes an upper crosspiece 110, a lower crosspiece 120 and a back panel assembly 130. A first storage space 140 with one side open is formed between the upper crosspiece and the lower crosspiece. In the first storage space A drawer 400 is installed inside, and the two ends of the upper rail 110 and the lower rail 120 are provided with tenon joints 111, 121. In order to increase the firmness of the tenon joint connection, inclined The counterbore 112, 122, the morti...

Embodiment 2

[0070] Example 2, see Figure 11 and Figure 12 , the consumer can also choose the structure of the drawer or the style door assembly, if the drawer is selected to assemble the drawer; Just install and assemble; other structural parts and their connections remain unchanged. The style door assembly 500 includes a door frame 510 installed on the front vertical rail of the side panel module assembly, on which a style door panel 520 and a variable style door handle 530 are installed; the door frame 510 and the style door panel of the style door assembly 500 520 can also be a glass door, a metal door, etc.

Embodiment 3

[0071] Example 3, see Figure 13 and Figure 14 , in order to improve the rationality of the structure, expand the style of the product, diversify the function and the utilization rate of the space, this embodiment increases the storage function on the basis of the embodiment 1, and the drawer 300 between the two side panel module assemblies 200 A partition 600 is installed below, and the partition is at a certain distance from the bottom. A second storage space 610 that is open around is formed between the partition 600 and the drawer 400. The partition 600 is provided with a connection gap 620, corresponding to the front vertical The positions of the shelves 210 and the rear vertical shelves 220 are provided with partition installation grooves (214, 224), and the gaps at the four corners of the partition are placed in the partition installation grooves, and are tightened by oblique locking screws under the partition 600 installation grooves. solid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com