Initial calibration method for control system of arc segmented motor of telescope

A technology of motor control and calibration method, which is applied in the field of servo control and can solve problems such as motor processing, transportation, and installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

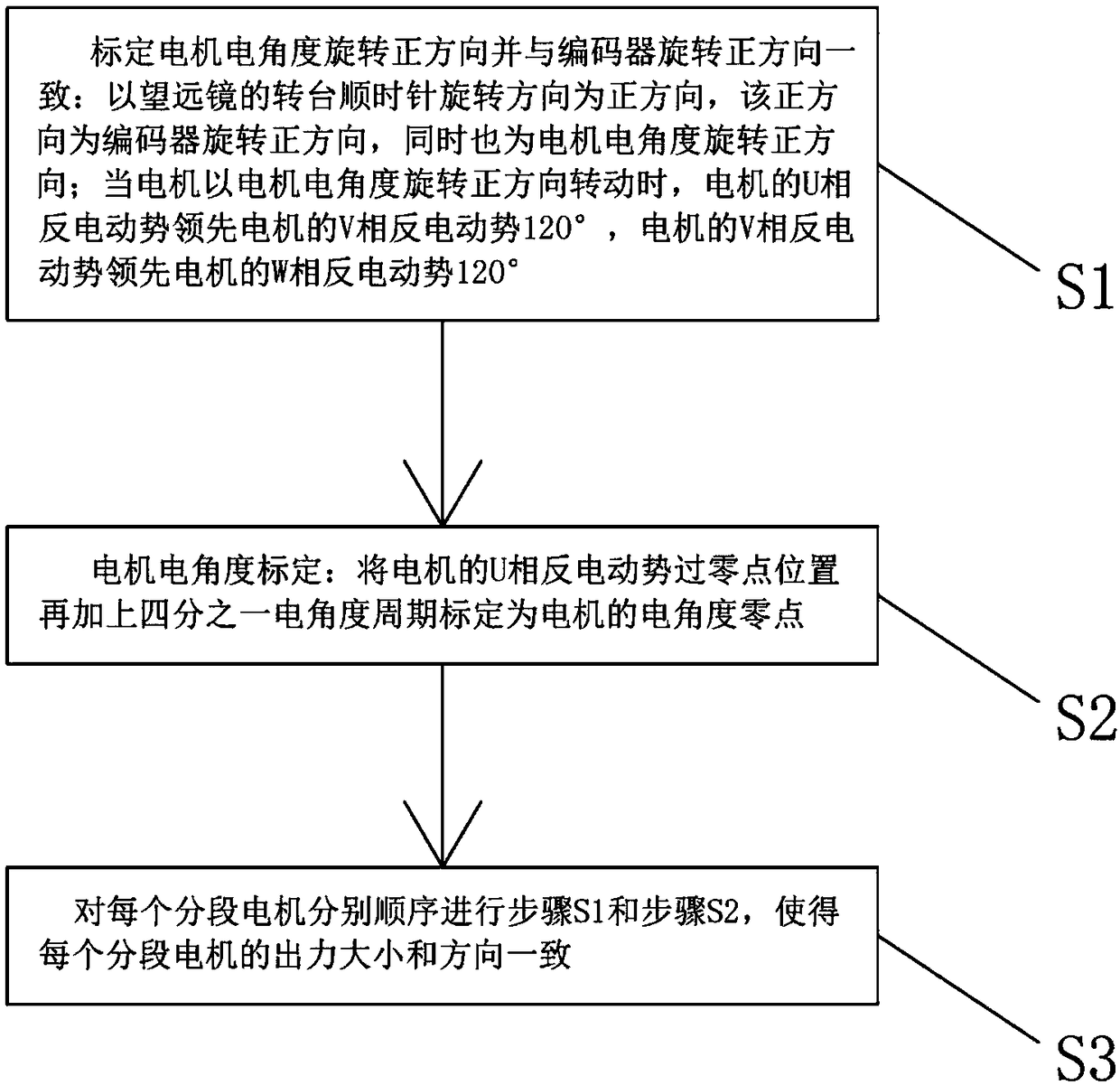

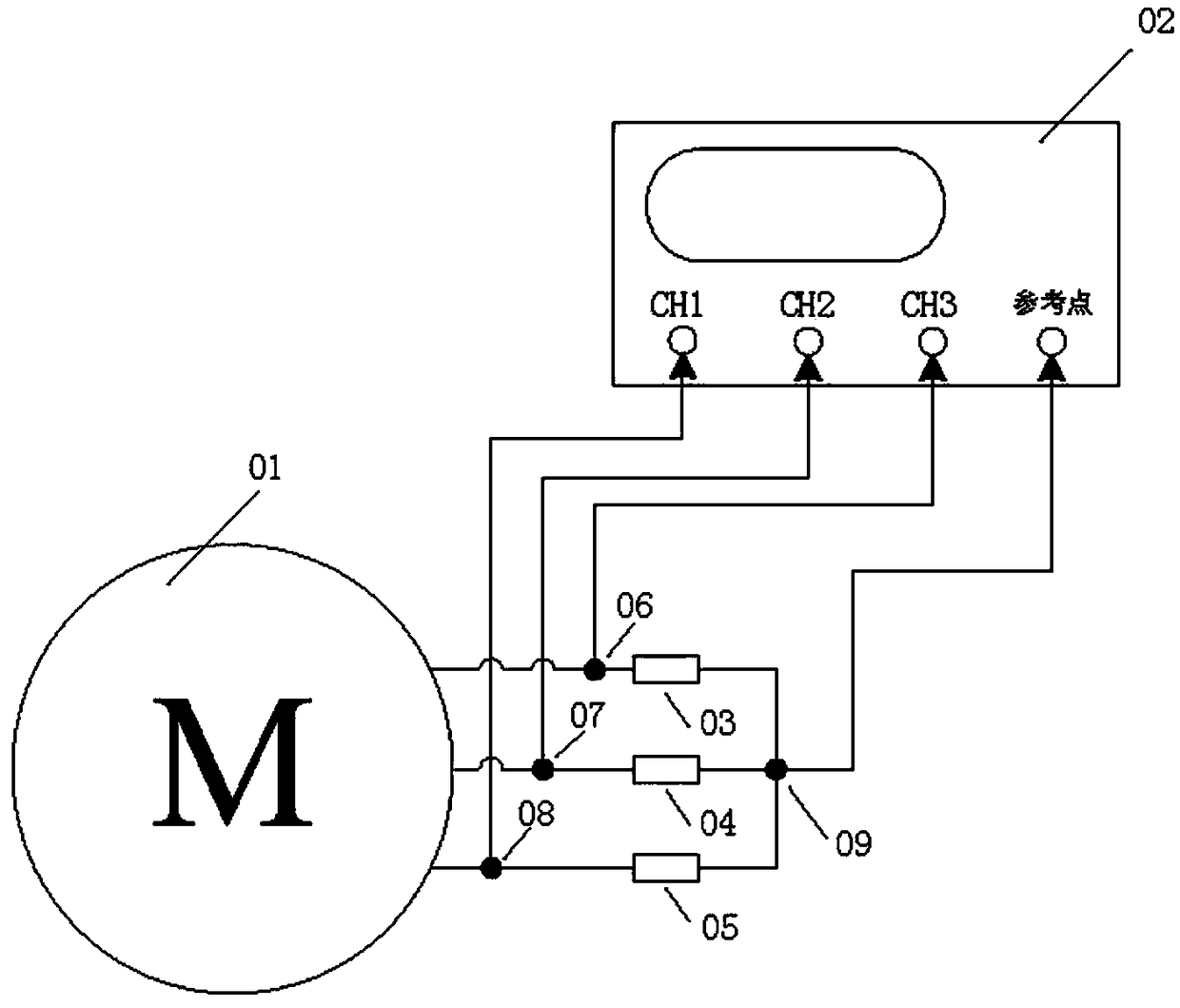

[0024] Please refer to Figure 1 to Figure 3 , the initial calibration method of the arc segment motor control system of a kind of telescope of the present invention, comprises the following steps:

[0025] Step S1. Calibrate the positive direction of the electrical angle rotation of the motor and be consistent with the positive direction of the encoder rotation: take the clockwise rotation direction of the turntable of the telescope as the positive direction, which is the positive direction of the encoder rotation, and also the positive direction of the electrical angle rotation of the motor ; When the motor rotates in the positive direction at the electrical angle of the motor, the U opposite electromotive force of the motor leads the V opposite electromotive force of the motor by 120°, and the V opposite electromotive force of the motor leads the W opposite electromotive force of the motor by 120°;

[0026] Step S2, electrical angle calibration of the motor: the zero-crossi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com