Improved INA feedforward control method for CO2 capture system after combustion

A technology of feed-forward control and feed-forward controller, applied in general control systems, adaptive control, control/regulation systems, etc., can solve problems such as unfavorable project implementation, non-obvious nonlinearity of capture system, and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

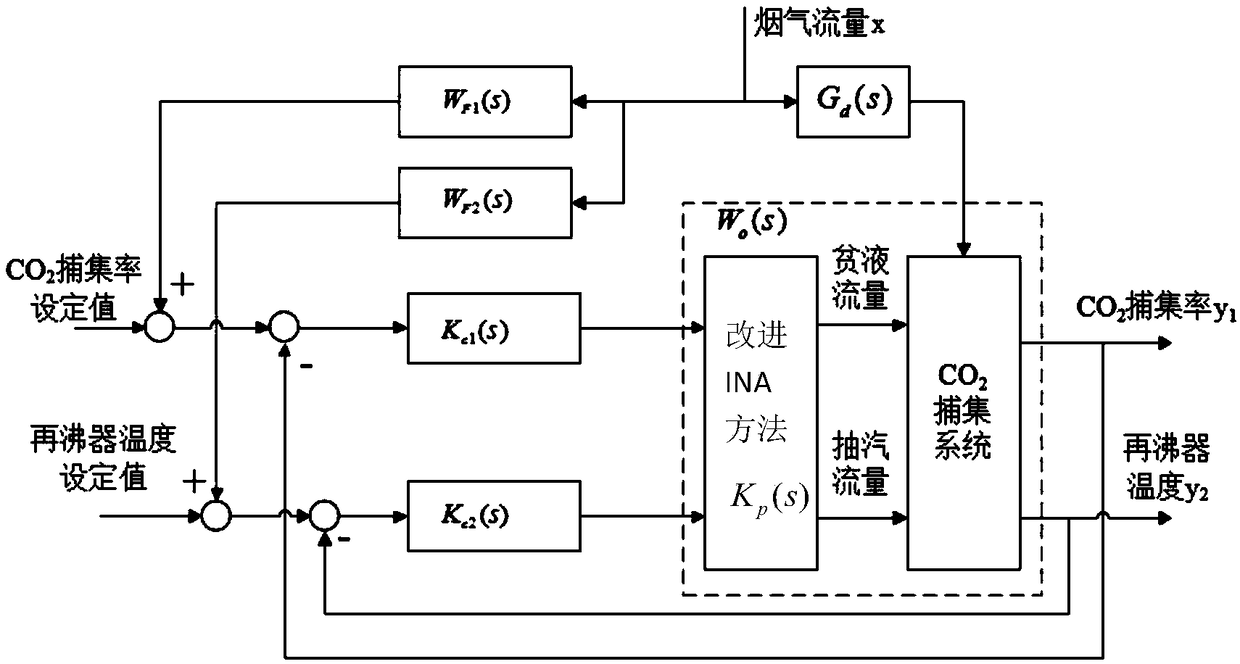

[0065] With the method proposed by the present invention for post-combustion CO 2 The improved INA feed-forward control method of the capture system is used to control CO after combustion in a 1MW thermal power unit 2 The application in the capture system simulation model is taken as an example. The control objective is to keep the temperature of the reboiler at 386K and keep the CO 2 The capture rate tracks the setpoint.

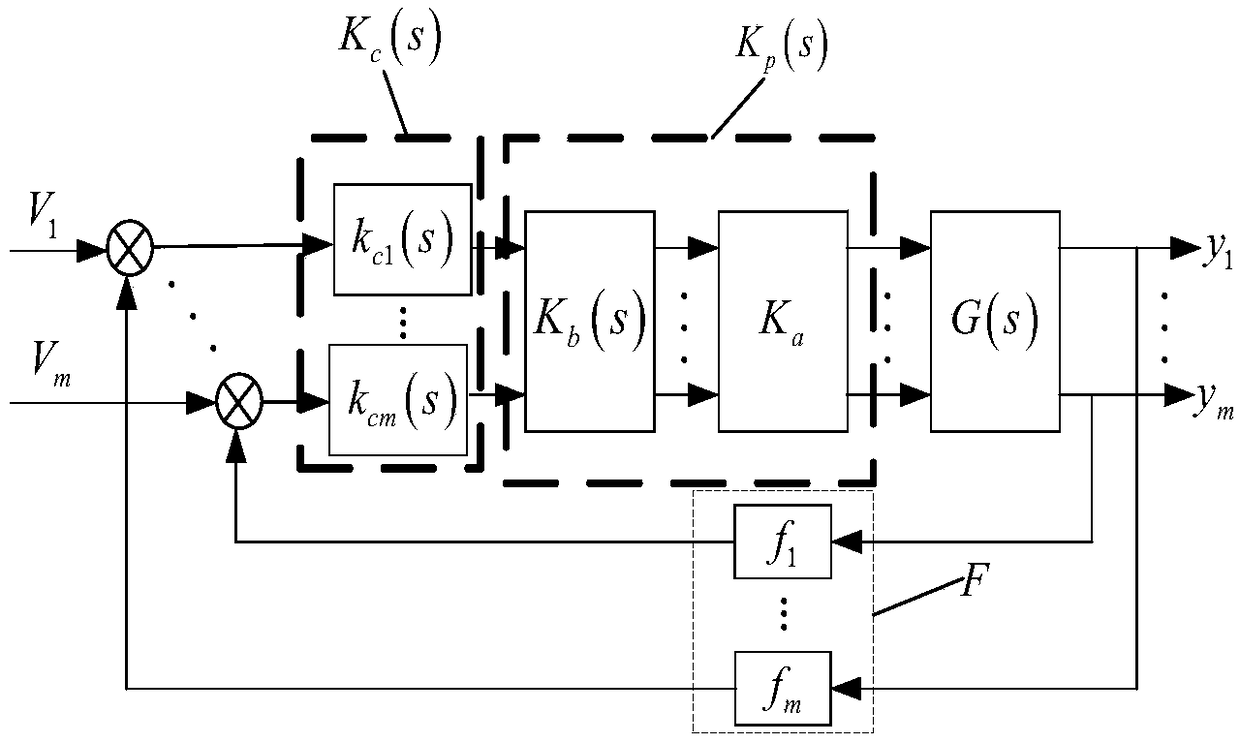

[0066] figure 1 It is a schematic block diagram of the principle of the existing INA control method, and the performance parameters and effects of the existing INA control method are detailed in Table 1 above. In order to overcome the shortcomings of existing INA control methods, figure 2 A schematic block diagram of the principle of the improved INA feedforward control method of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com