Device and method for performing ultimate drawing test of anchor plate under plane strain condition

A technology of plane strain and pull test, applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of unable to study the pull-out of anchor plate, and achieve stable pull-out angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

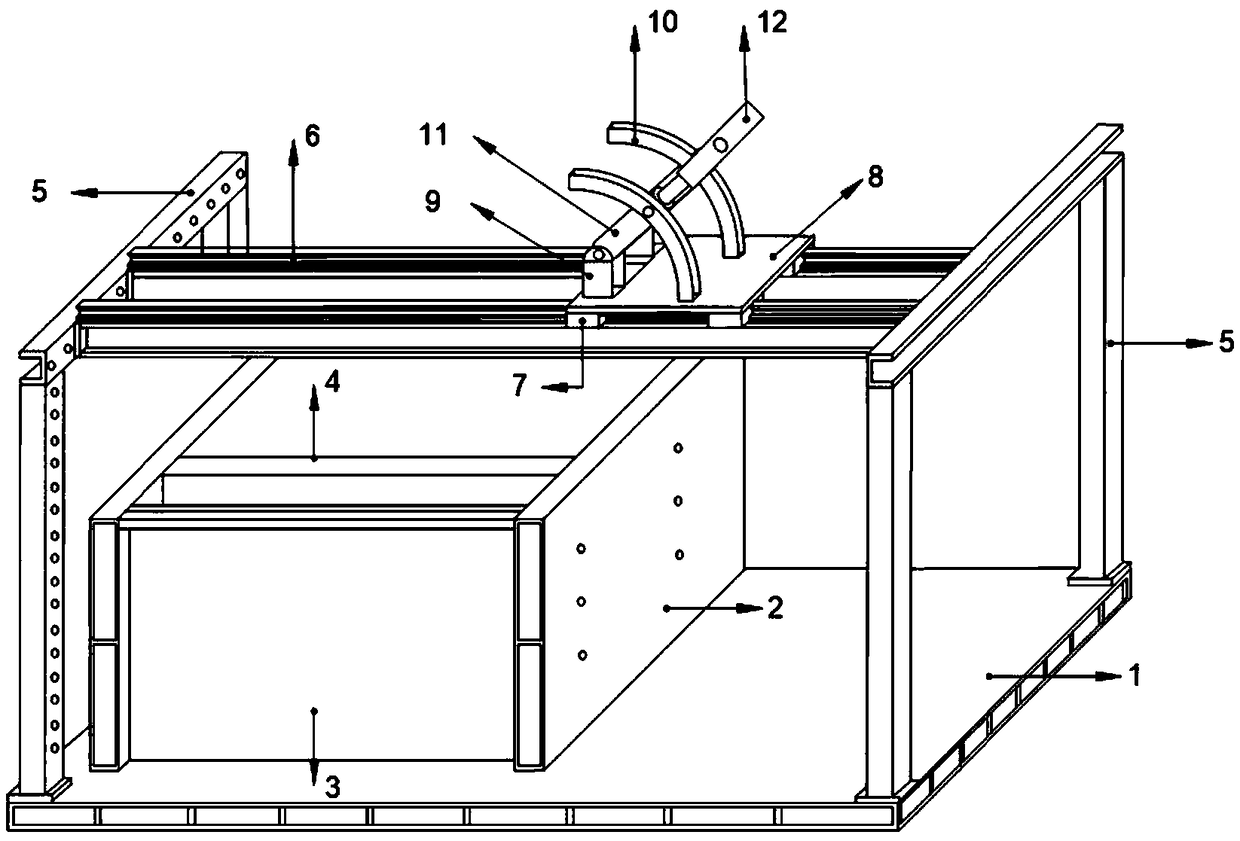

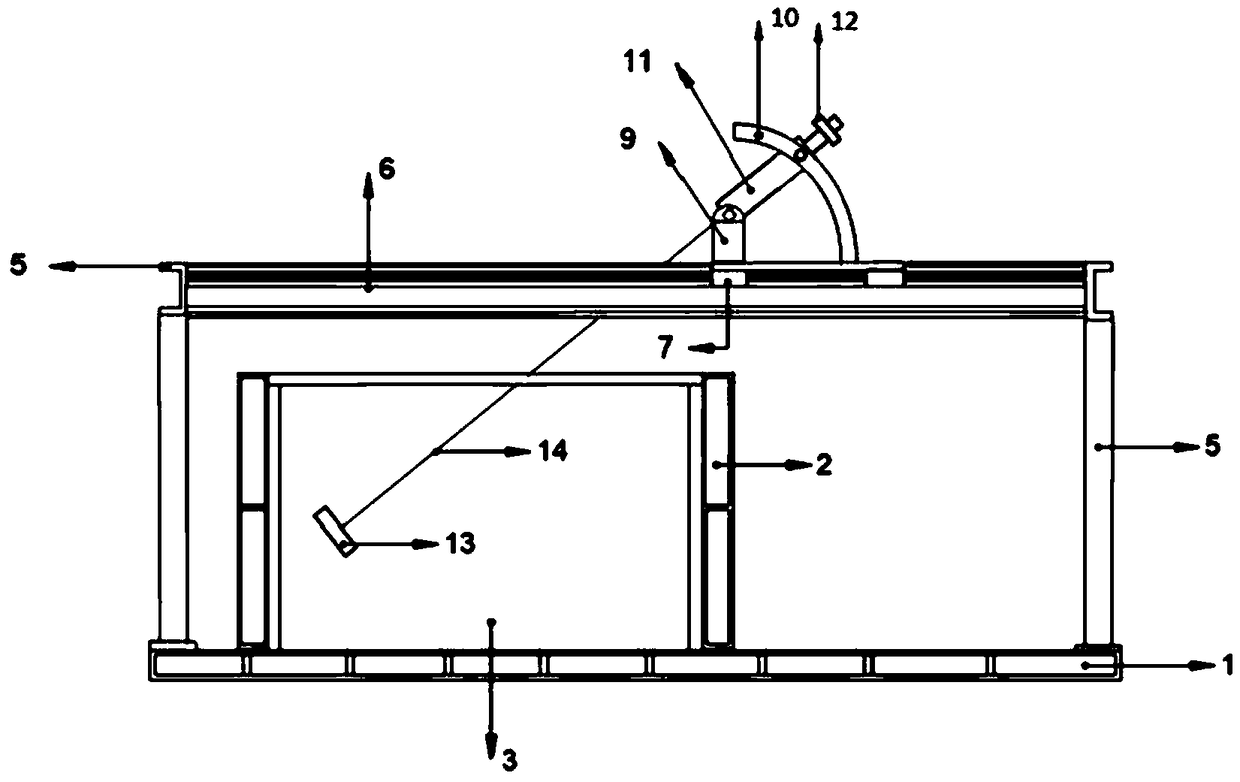

[0037] Such as figure 1 As shown, an anchor plate ultimate pullout test device under plane strain conditions includes a base 1, a test soil box, a main support, a retaining plate 4, an anchor plate 13, an anchor rod 14, a displacement device and a loading device, The base 1 is provided with a test soil box, and the soil body is filled in the test soil box; one side of the test soil box adopts plexiglass 3 panels to realize transparency, and the test soil box has a non-transparent side wall Drill holes so that the anchor rod 14 can pass through; the soil retaining plate 4 is located in the soil box and can be moved to respectively realize the test device for the front fracture surface of the anchor plate 13 and the ultimate bearing capacity; the main support end The part is connected with the displacement device. Described main support adopts steel support 5, as figure 1 As shown in , the steel bracket 5 includes four vertical columns and two horizontal columns distributed in...

Embodiment 2

[0053] The difference between Embodiment 2 and Embodiment 1 is that both ends of the slide rail 6 are fixed to the columns, mainly to realize the horizontal loading of the anchor plate 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com