Rotary wood kiln for firing potteries

A pottery and firewood kiln technology, applied in the field of kiln structure, can solve the problems that the quality and appearance of pottery are difficult to be effectively controlled, the amount of ash falling is also large, and the color deviation of pottery is large, so as to improve the appearance, value and structure of pottery. The effect of compactness and small color deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

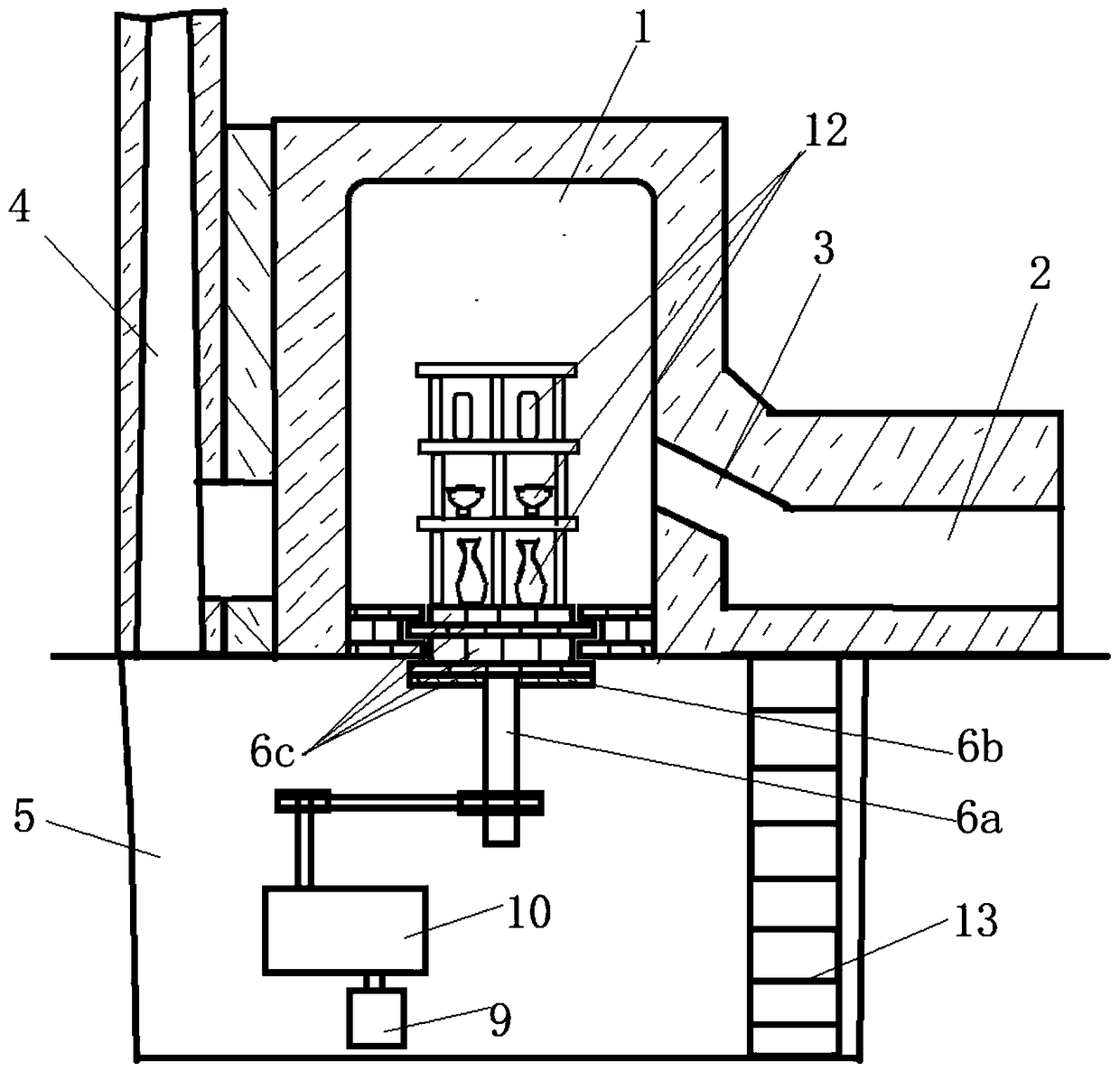

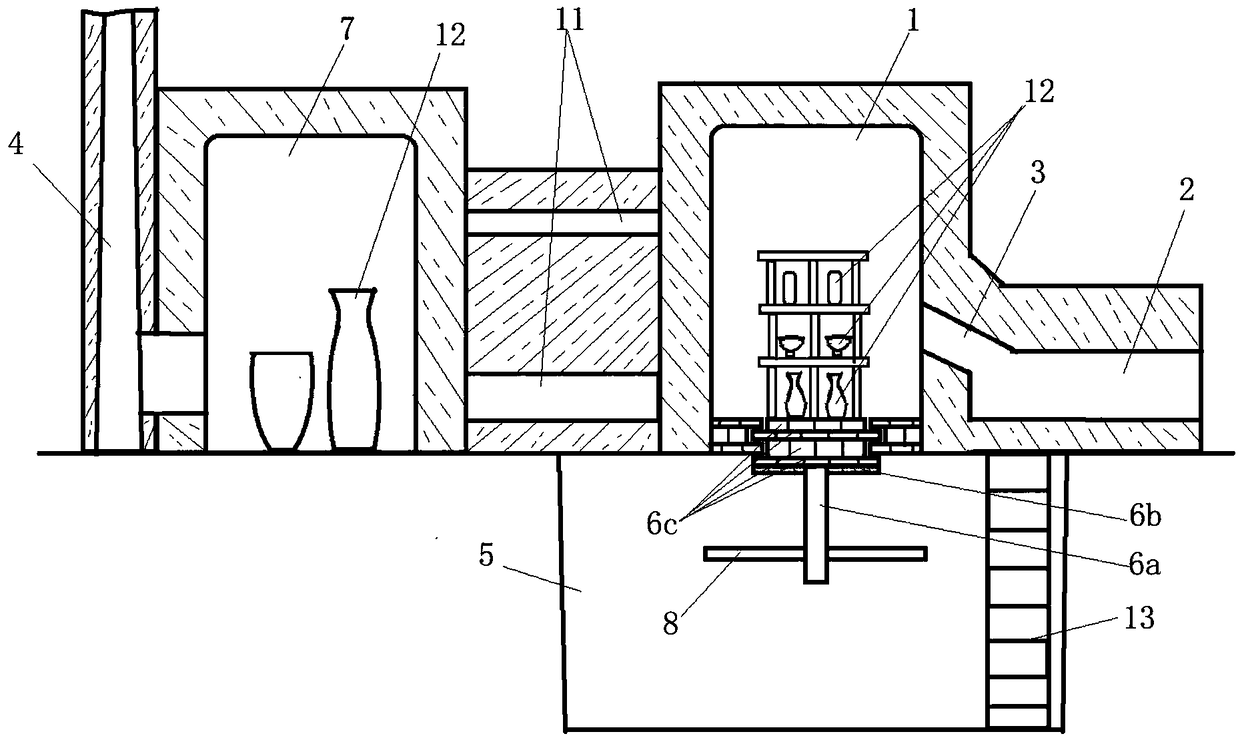

[0015] Such as figure 1 The shown rotary firewood kiln for firing pottery includes a kiln chamber 1 made of bricks and stones, a furnace 2 located next to the kiln chamber, a fire channel 3 connecting the kiln chamber and the furnace chamber, a chimney 4 connecting the kiln chamber, and a furnace located next to the kiln chamber. Room 5 below the basement. At the center of the bottom of the kiln chamber, there is a circular channel connected with the basement, and a turntable mechanism for placing pottery is arranged in the circular channel. The central axis 6a of the turntable mechanism extends vertically downwards into the basement 5, and the center The lower part of the shaft is connected with a rotating mechanism that drives the central shaft to rotate. The basement is provided with a ladder or steps 13 for staff to go up and down.

[0016] The turntable mechanism includes a circular tray 6b made of steel plate set on the central axis 6a, at least two layers of disc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com