Downhole oil and water separation pipe column

A technology of oil-water separation and oil-water separator, applied in the direction of drilling pipe, casing, drilling equipment, etc., can solve the problems of precise adjustment, failure, large outer diameter, etc., and achieve a wide application range, simple composition structure, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

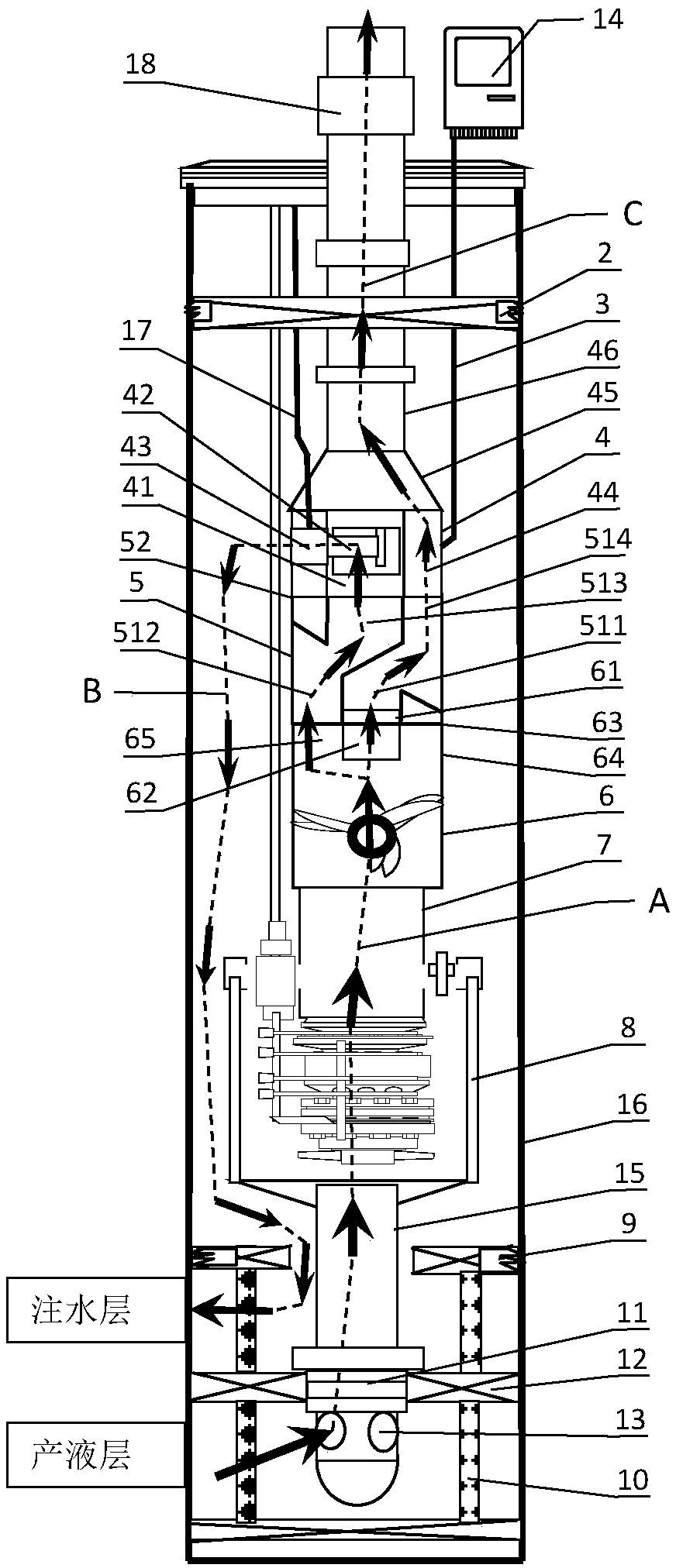

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0021] see figure 1 , a new type of downhole oil-water separation and monitoring string, which is a single-pipe, one-trip string structure, including a cable packer 2 connected in series through the tubing 7 from top to bottom, a reinjection water measurement and adjustment work cylinder 4, and an X-type Converter 5, oil-water separator 6, canned pump system 8, positioning seal 11 and perforated pipe 13; the positioning seal 11 is inserted into the isolation packer 12 arranged between the water injection layer and the liquid production layer; the The isolation packer 12 is connected with the top packer 9 (ie, the second packer) disposed above the water injection layer through the screen 10 .

[0022] A new type of downhole oil-water separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com