Method and structure for improving pull rod of gate or trash rack

A trash rack and tie rod technology, which is used in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as difficult maintenance, large deflection of tie rods, and losses, and prevent the pin shaft from breaking off the tie rod due to shearing of the fixing bolts. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, and those not described in detail in the present invention are conventional technical means known to those skilled in the art.

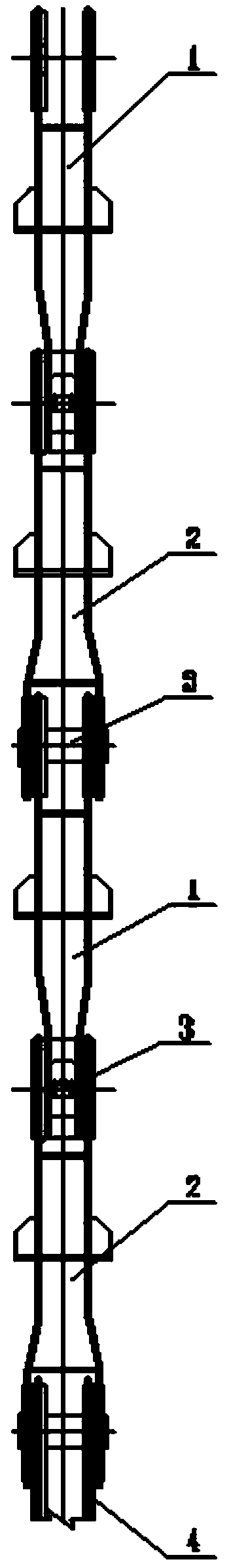

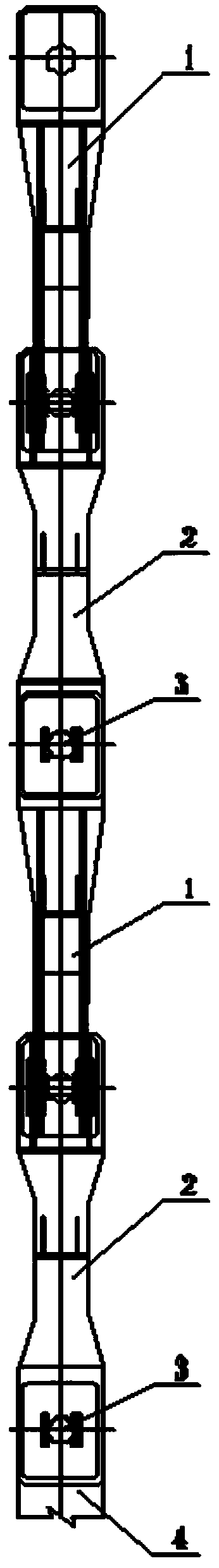

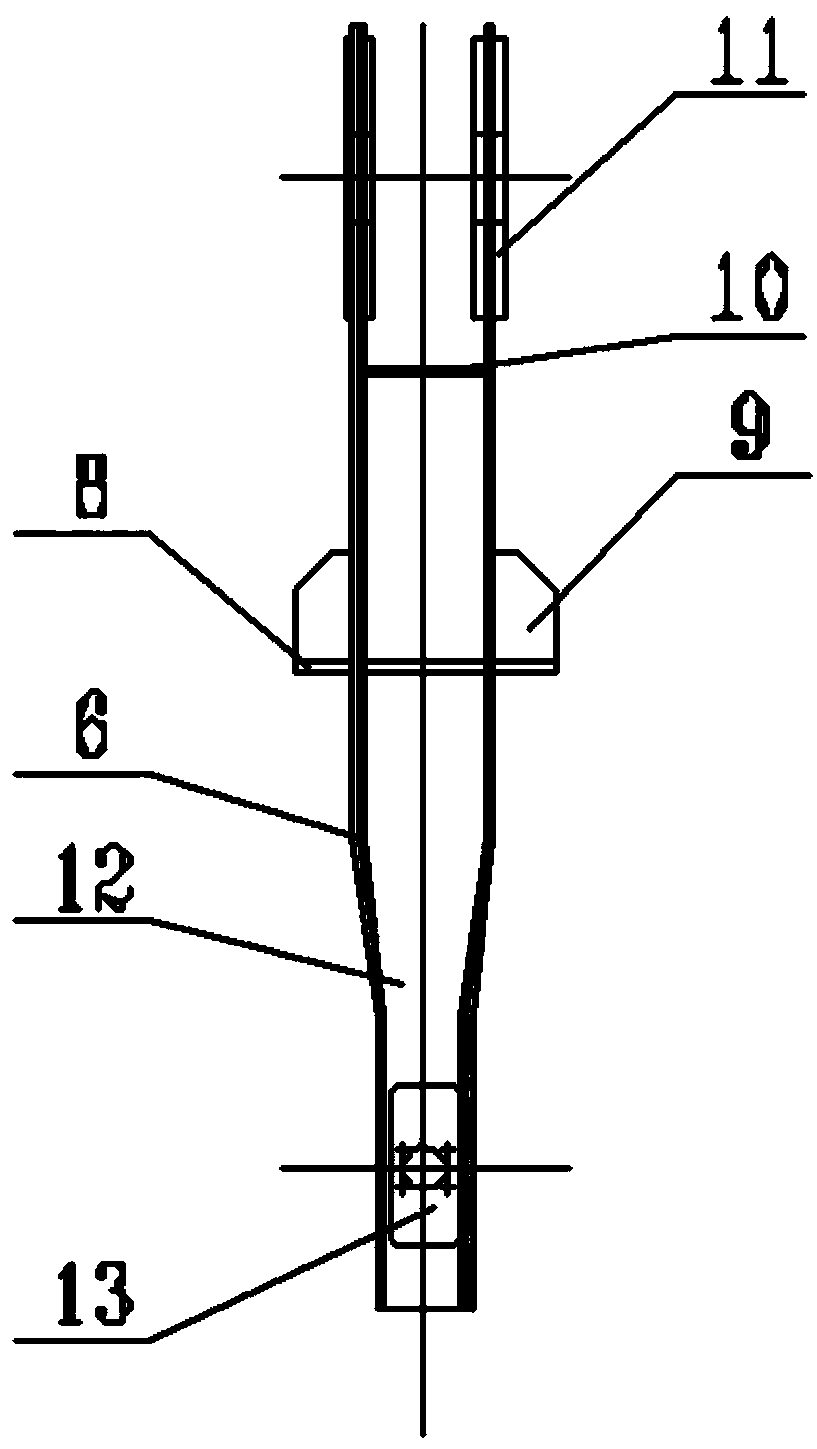

[0022] Please refer to Figure 1-6 : First, from figure 1 We can see that the pull rods of the gate and the trash rack of the present invention are formed by connecting multiple pull rod units in series. Axis 3 is connected, the bottom of the tie rod is connected to the gate or trash rack, and the top of the tie rod is connected to the gate or trash rack hoist head through the lifting hole. The bottom section of the lower tie rod 2 is connected to the lifting lug 4 of the gate or trash rack through the pin shaft 3; the topmost section of the upper tie rod 1 is connected to the hoisting device such as the lifting head of the winch hoist through the tie rod hanging hole .

[0023] In the present invention, the structures of the upper tie rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com