A kind of preparation method of solid bacterial agent for rice crops

A solid inoculum and crop technology, applied in microorganism-based methods, biochemical equipment and methods, fixed on/in organic carriers, etc., can solve the problem of not being able to simultaneously load biological bacterial fertilizers and chemical fertilizers, fertilizer manpower Waste of material resources, non-interference and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

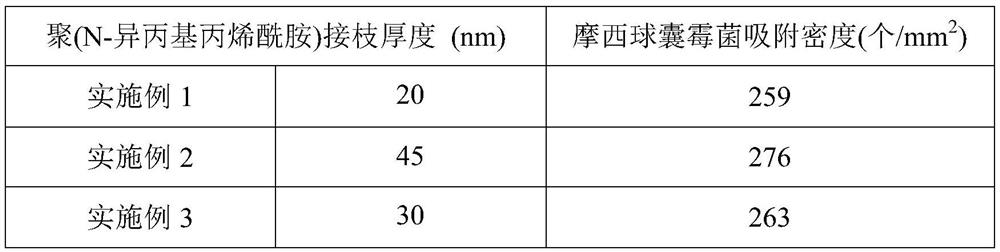

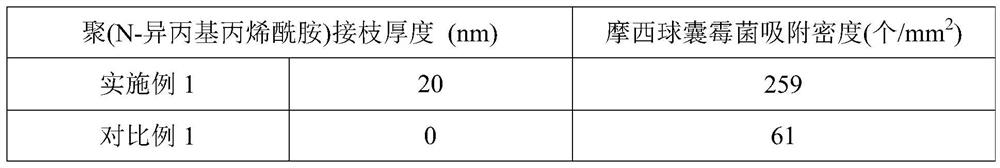

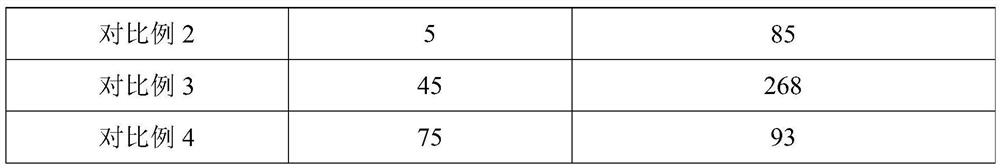

Embodiment 1

[0036] Embodiment 1: the preparation steps of solid bacterial agent for rice crops are as follows:

[0037] (1) drying the fertilizer of 35 parts by weight of ammonium sulfate, 20 parts of potassium chloride, 30 parts of superphosphate, 5 parts of magnesium sulfate, and 10 parts of ammonium chloride, and grinding into fine powder;

[0038] (2) 40g of sodium alginate and 25g of polyvinyl alcohol were dissolved in deionized water, and left for 5 hours until fully dissolved to obtain a mixed solution;

[0039] (3) putting the Glomus mosesii strain into the culture medium and cultivating it for 7 days to obtain the bacterial liquid;

[0040] (4) Add the fertilizer fine powder of step (1) and 7g of 1800 mesh CaCO in the resulting mixed solution under stirring 3 ;

[0041] (5) solution gained in step (4) is dripped into 2wt% CaCl 2 In saturated boric acid solution, gel balls are formed after curing for 14 hours;

[0042] (6) Take out the gel ball, put it into a 0.1mol / L hydrochl...

Embodiment 2

[0045] Embodiment 2: the preparation steps of solid bacterial agent for rice crops are as follows:

[0046] (1) drying the fertilizer of 20 parts by weight of ammonium sulfate, 30 parts of potassium chloride, 35 parts of superphosphate, 5 parts of magnesium sulfate, and 10 parts of ammonium chloride, and grinding into fine powder;

[0047] (2) 50g of sodium alginate and 30g of polyvinyl alcohol were dissolved in deionized water, and left for 6 hours until fully dissolved to obtain a mixed solution;

[0048] (3) putting the Glomus mosesii strain into the culture medium and culturing it for 6 days to obtain the bacterial liquid;

[0049] (4) Add the fertilizer fine powder of step (1) and 10g of 800 mesh CaCO in the resulting mixed solution under stirring 3 ;

[0050] (5) solution gained in step (4) is dripped into 3wt% CaCl 2 In saturated boric acid solution, gel balls are formed after curing for 18 hours;

[0051] (6) Take out the gel ball, put it into a 0.1mol / L hydrochlor...

Embodiment 3

[0054] Embodiment 3: the preparation steps of solid bacterial agent for rice crops are as follows:

[0055] (1) drying the fertilizer of 15 parts by weight of ammonium sulfate, 30 parts of potassium chloride, 30 parts of superphosphate, 10 parts of magnesium sulfate, and 15 parts of ammonium chloride, and grinding into fine powder;

[0056] (2) 70g of sodium alginate and 20g of polyvinyl alcohol were dissolved in deionized water, and left for 5 hours until fully dissolved to obtain a mixed solution;

[0057] (3) putting the Glomus mosesii strain into the culture medium and cultivating it for 7 days to obtain the bacterial liquid;

[0058] (4) Add the fertilizer fine powder of step (1) and 15g of 2500 mesh CaCO in the resulting mixed solution under stirring 3 ;

[0059] (5) solution gained in step (4) is dripped into 4wt% CaCl 2 In saturated boric acid solution, gel balls are formed after curing for 19 hours;

[0060] (6) Take out the gel ball, put it into a 0.1mol / L hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com