High-efficiency extraction and refining method and application of tree moss absolute oil

A tree moss and application technology, which is applied in the application field of efficient preparation of tree moss net oil and cigarette flavoring, can solve the problems of heat-not-burn cigarette smoking experience, influence on electronic cigarettes, low net oil yield, etc., and it is not easy to achieve The effect of solvent residue, simplified operation process and less loss of aroma components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

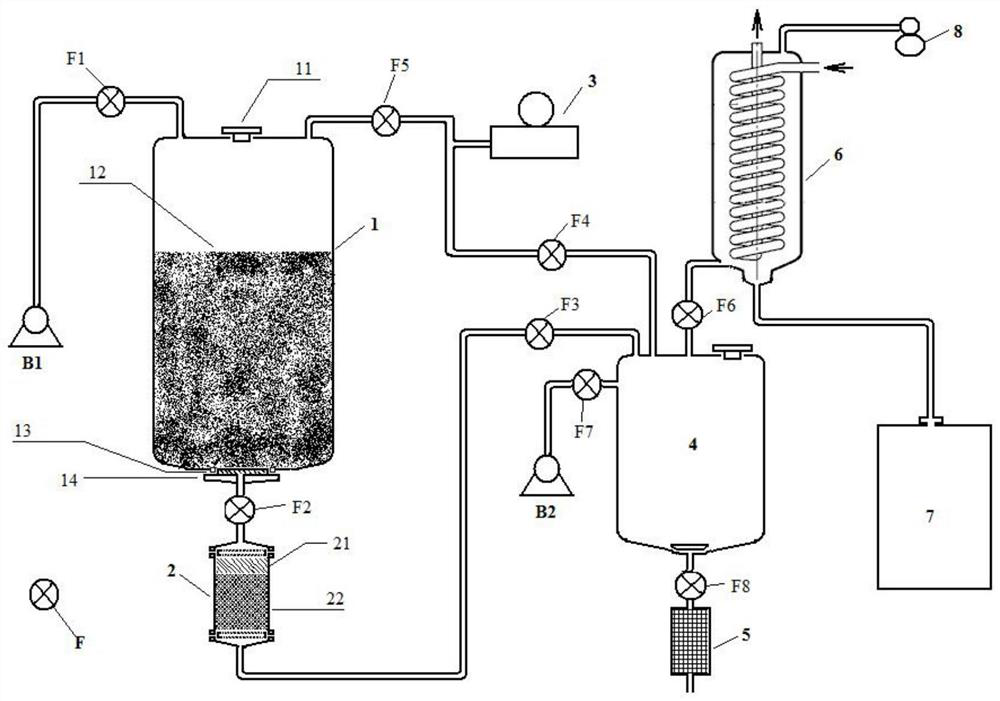

[0068] Extract the raw material with the moss sample after drying and crushing, the sample is ground to 20 meshes after roasting, the feeding amount is 200kg, join in the ultrasonic extraction tank 1, seal the feed port and the discharge port, add the tree moss sample weight 5 times the amount of methyl acetate, ultrasonic extraction at 45°C for 35 minutes, after the extraction, start the air compressor to pressurize the ultrasonic extraction tank, let the extract pass through the filter sieve plate at the outlet and lead to the chromatography column for purification.

[0069] After the extract passed through the chromatographic column was transferred to the concentration tank, the temperature of the concentration tank was raised to 80° C., and at the same time, the vacuum pump was started to concentrate the extract until the methyl acetate was evaporated to dryness. Return the methyl acetate recovered after the sample concentration to the ultrasonic extraction tank 1, and ultr...

Embodiment 2

[0072] The treemoss absolute oil prepared by the above method is used in cigarette cut tobacco, the tree moss absolute oil is added to the cigarette cut tobacco at a ratio of 5 / 100,000 of the weight of the cut tobacco, and the cut tobacco is made into finished cigarettes for evaluation and smoking. The results show that: the tree moss absolute oil prepared by the present invention can effectively strengthen the refreshing grass fragrance and rich resinous fragrance of cigarette products, the aroma quantity and aroma quality of cigarette smoking are all improved, and the miscellaneous gas of cigarette smoking can also be covered. The comfort of cigarette smoking is improved, which is better than that of the control sample (that is, the cigarette without adding the moss absolute obtained by the present invention). or,

[0073]In the cigarette filter molding process, the moss absolute oil obtained in the present invention is added to triacetin according to the 1wt% amount of plas...

Embodiment 3

[0076] During the preparation process of the electronic cigarette liquid, the tree moss absolute oil of the present invention is added to the tree moss-flavored electronic cigarette liquid in a proportion of 5% by weight. The result shows: the total score of the tree moss absolute oil of the present invention is higher, and the advantages are mainly manifested in the characteristic fresh grass fragrance and strong resinous fragrance of tree moss, good aroma quality and sufficient aroma amount; secondly, it is light in miscellaneous gas, The aftertaste is cleaner and better than that of the control sample (that is, the electronic cigarette without adding the tree moss absolute oil obtained in the present invention).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com