Method for separating and purifying N-acetylneuraminic acid from material containing polysialic acid

A technology of acetylneuraminic acid and polysialic acid, which is applied in the preparation of sugar derivatives, sugar compounds with non-glycosyl groups, chemical instruments and methods, etc., can solve the problems of high price, complicated process, and few separation and purification methods. , to achieve the effect of low cost, simple steps and meeting market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the method for separating and purifying N-acetylneuraminic acid from materials containing polysialic acid is as follows:

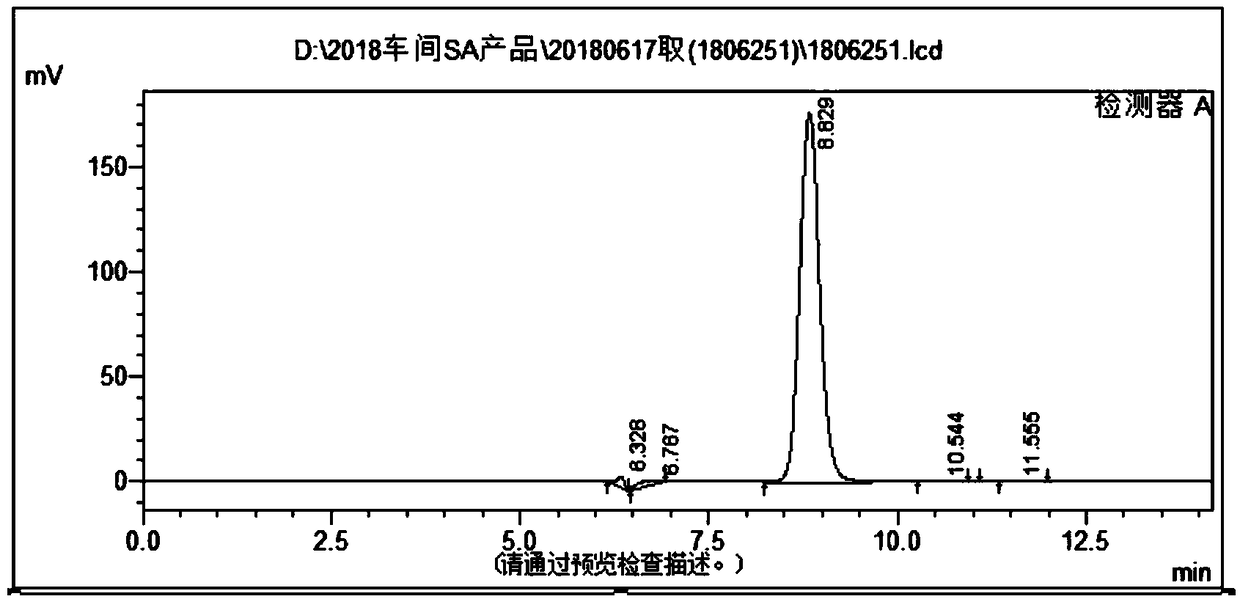

[0030] 1. Separation of bacterial liquid: use polysialic acid fermentation liquid produced by microbial fermentation as raw material, add polyacrylamide accounting for 15% of the mass of the fermentation liquid for bacterial flocculation and precipitation, and then filter with a ceramic membrane with a pore size of 50nm to make the bacterial The body and the fermentation broth were thoroughly separated to obtain a sterilized fermentation broth, which was detected by high-performance liquid chromatography, and the content of the target product polysialic acid in the fermentation broth had almost no change before and after sterilization;

[0031] 2. Removal of salt ions and miscellaneous proteins: The sterilized fermentation broth is filtered with a 10,000D organic membrane, and a large amount of water is added until the conductivit...

Embodiment 2

[0038] In this embodiment, the method for separating and purifying N-acetylneuraminic acid from materials containing polysialic acid is as follows:

[0039] 1. Separation of bacterial liquid: use polysialic acid fermentation liquid produced by microbial fermentation as raw material, add polyacrylamide accounting for 20% of the mass of the fermentation liquid for bacterial flocculation and precipitation, and then filter with a ceramic membrane with a pore size of 100nm to make the bacterial The body and the fermentation broth were thoroughly separated to obtain a sterilized fermentation broth, which was detected by high-performance liquid chromatography, and the content of the target product polysialic acid in the fermentation broth had almost no change before and after sterilization;

[0040] 2. Removal of salt ions and miscellaneous proteins: The sterilized fermentation broth is filtered with an 8000D organic membrane, and a large amount of water is added until the conductivit...

Embodiment 3

[0047] In this embodiment, the method for separating and purifying N-acetylneuraminic acid from materials containing polysialic acid is as follows:

[0048] 1. Separation of bacterial liquid: use polysialic acid fermentation liquid produced by microbial fermentation as raw material, add polyacrylamide accounting for 25% of the mass of the fermentation liquid for bacterial flocculation and precipitation, and then filter with a ceramic membrane with a pore size of 200nm to make the bacterial The body and the fermentation broth were thoroughly separated to obtain a sterilized fermentation broth, which was detected by high-performance liquid chromatography, and the content of the target product polysialic acid in the fermentation broth had almost no change before and after sterilization;

[0049] 2. Removal of salt ions and miscellaneous proteins: The sterilized fermentation broth is filtered with an 8000D organic membrane, and a large amount of water is added until the conductivit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com