A printing machine with cleaning function

A printing machine and functional technology, which is applied in the field of printing machines with cleaning function, can solve the problems of paper adsorption, loss of paper patterns, and decline in paper aesthetics, and achieve the effect of avoiding damage to paper and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

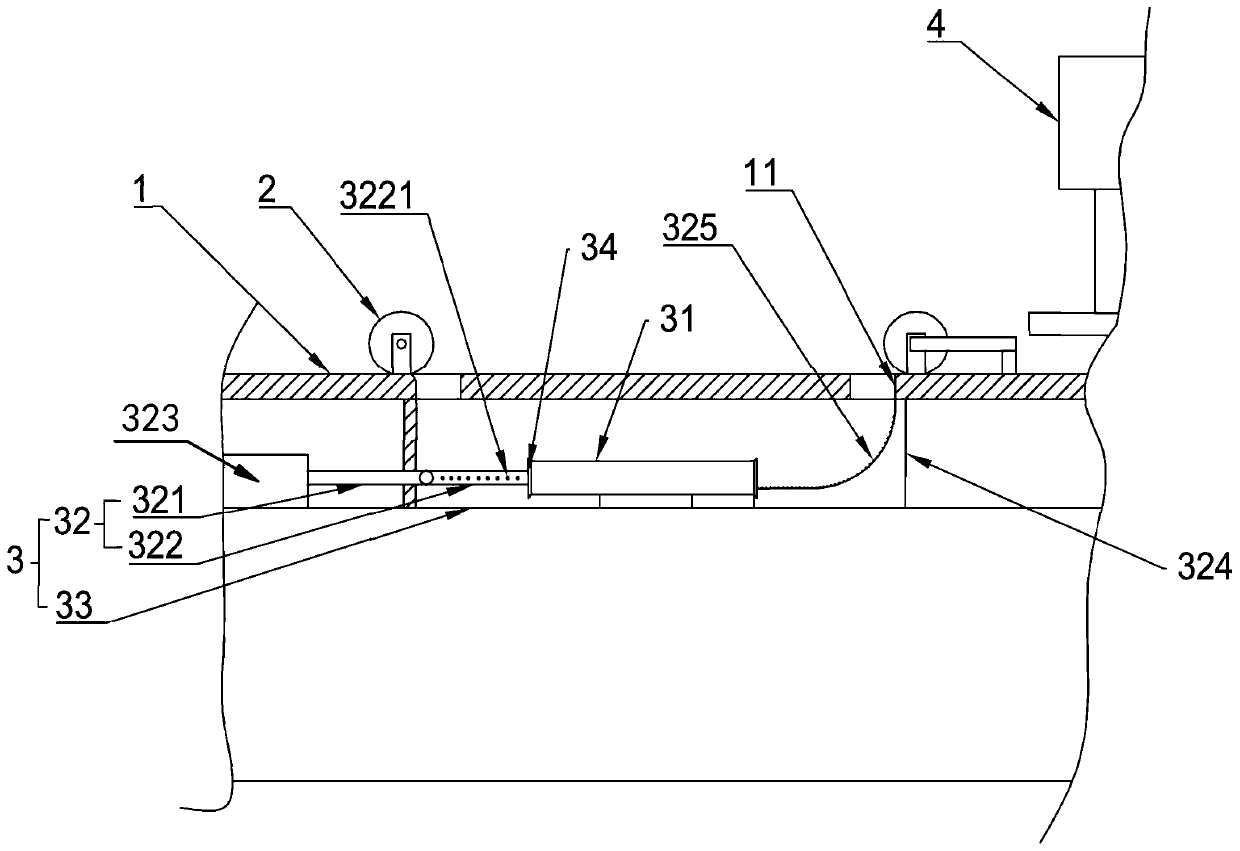

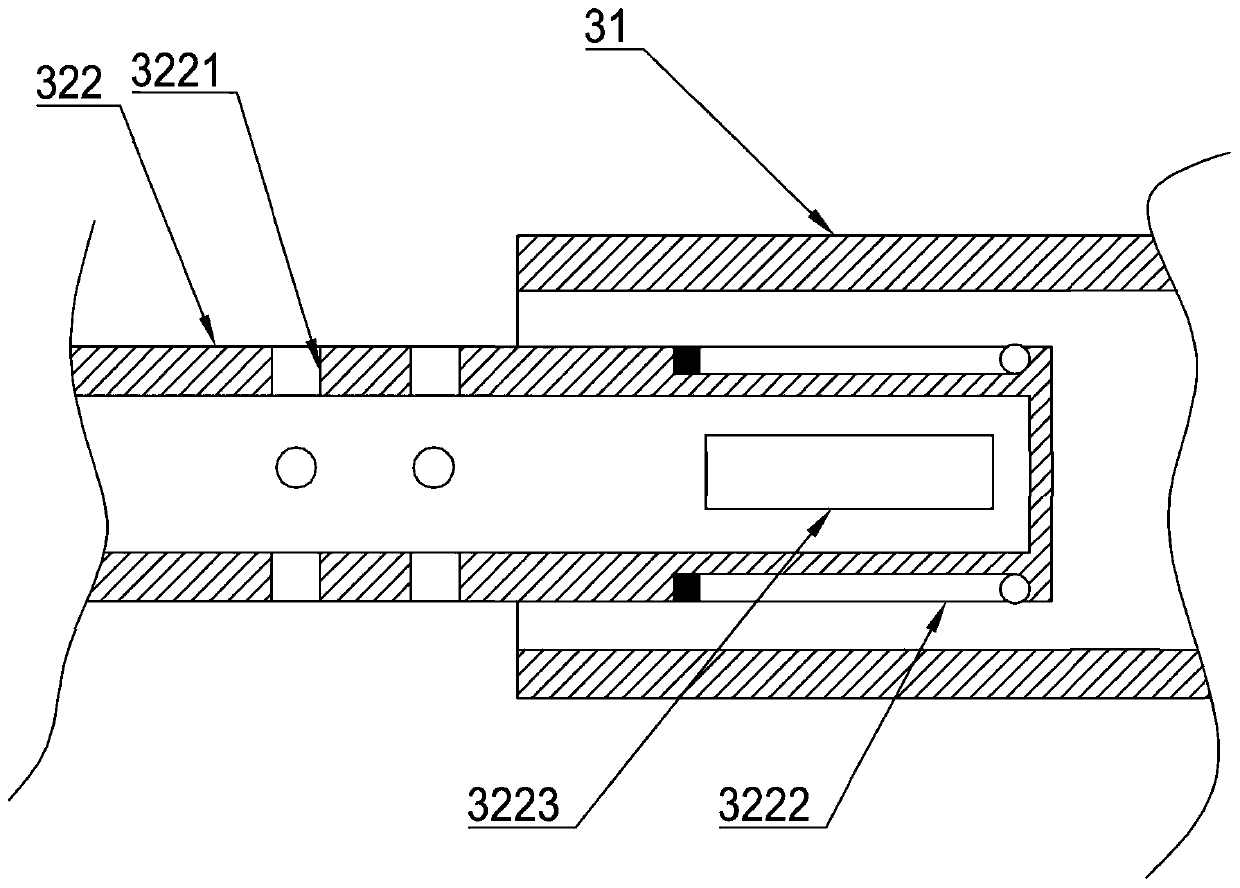

[0016] As an improved specific embodiment, the cleaning column 32 includes a base column 321 and a turning column 322, and a cleaning cylinder 323 is provided at a position below the frame 1 relative to the paper conveying device 2, and the cleaning cylinder 323 The cylinder body is fixed on the cleaning table 33, the base column 321 is coaxially fixed on the push rod of the cleaning cylinder 323, and the crutch column 322 is elastically hinged on the end of the base column 321 facing away from the cleaning cylinder 323, and the frame 1 A turning track 324 is provided below the printing device 4, and the turning track 324 is arranged relative to the end of the cleaning sleeve 31, so that when the cleaning cylinder 323 drives the cleaning column 32 to stretch out from the cleaning sleeve 31 with paper, The turning column 322 is turned upwards, and several air outlet holes 3221 are provided on the side wall of the turning column 322. When the turning column 322 is turned upwards ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com