A kind of concrete prefabricated block mold equipment

A technology of prefabricated blocks and concrete, applied in the direction of molds, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of difficult cleaning, artificial concrete overflow, etc., and achieve the effect of preventing air bubbles and preventing overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

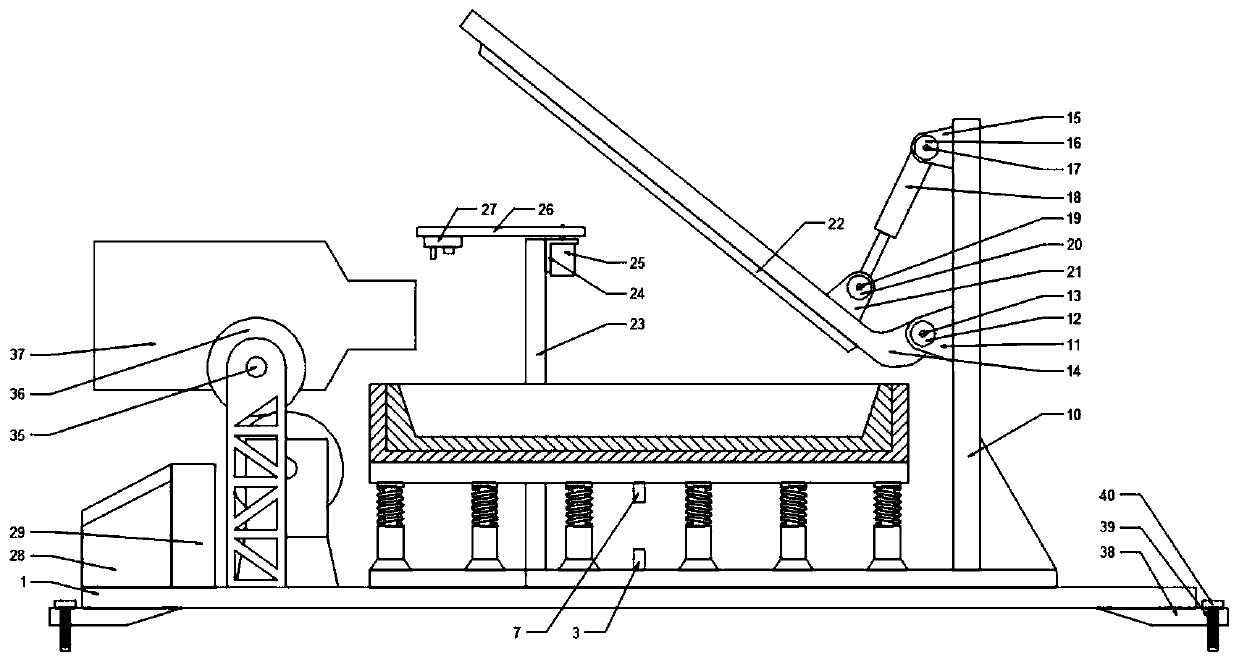

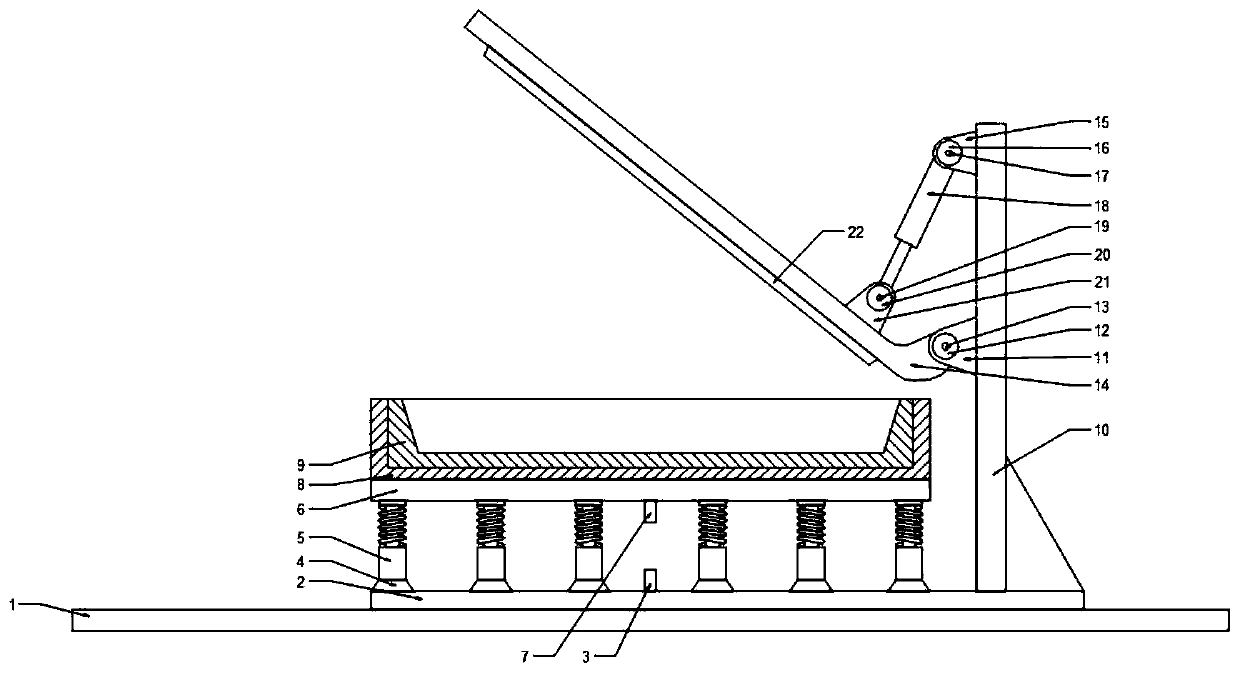

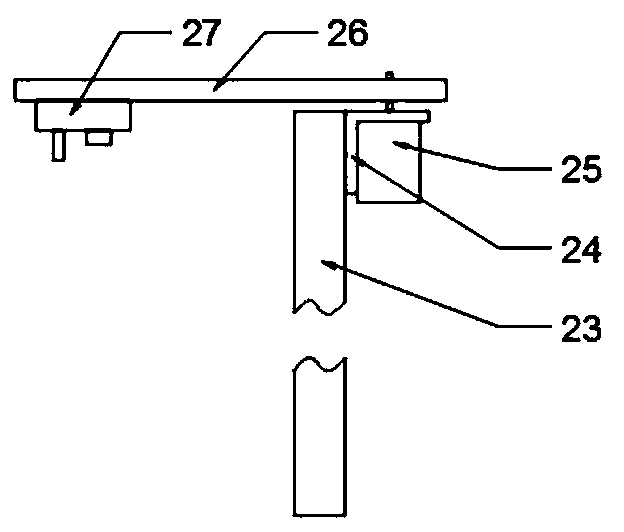

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown in -5, a concrete prefabricated block mold equipment includes a base 1, the base 1 is located above the ground, a mold mechanism is arranged above the base 1, and the mold mechanism is fixed by a mold platform fixedly connected above the base 1 Frame 2, the mold table distance sensor transmitter fixedly connected at the center of the upper surface of the mold table fixed frame 2 3, several mold table support hydraulic buffer installation frames evenly distributed above the mold table fixed frame 2 4, installed on the mold table The mold table supporting hydraulic buffer 5 on the supporting hydraulic buffer mounting frame 4, the mold table mounting frame 6 fixedly connected with several mold table supporting hydraulic buffers 5 above the mold table supporting hydraulic buffer 5, located on the mold table mounting frame 6 Die table distance sensor receiver ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com