Numerical control milling machine angle-adjustable four-axis rotary workbench

A technology of rotary table and CNC milling machine, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of inability to process negative angle cylindrical parts, easy to produce overcut phenomenon, low work efficiency, etc., to achieve Increase the effective processing range, improve the effective utilization rate, and the effect of easy and understandable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

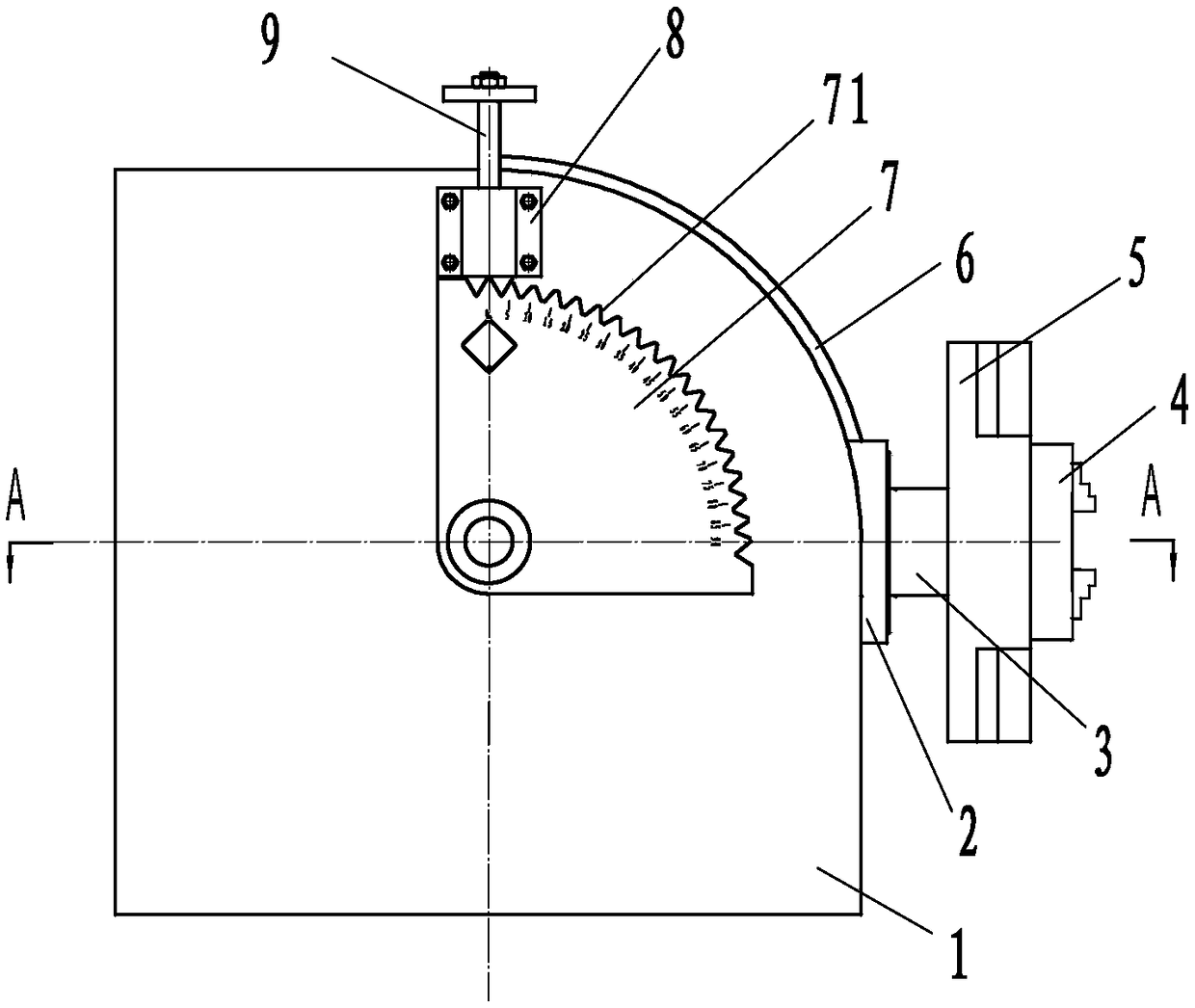

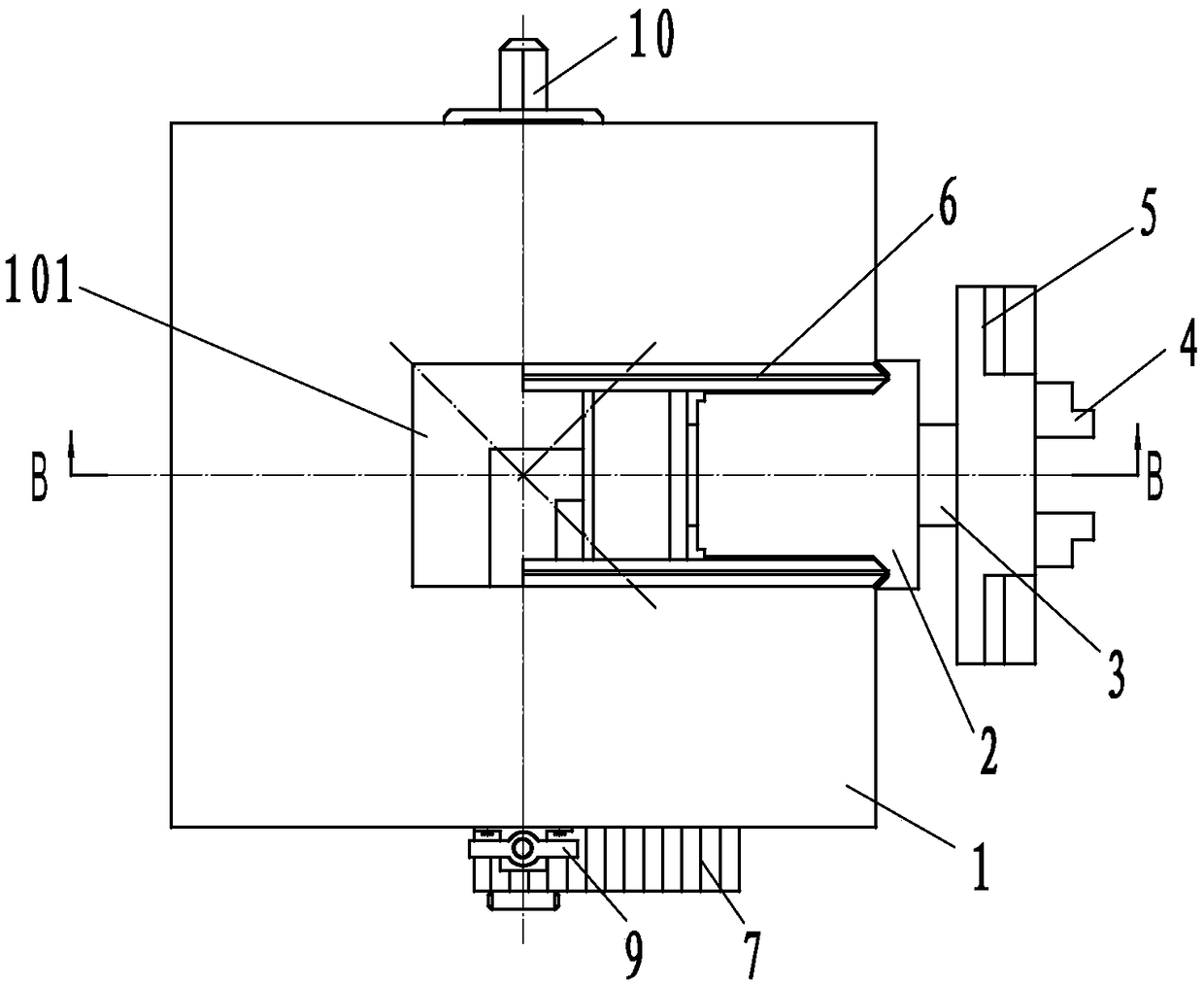

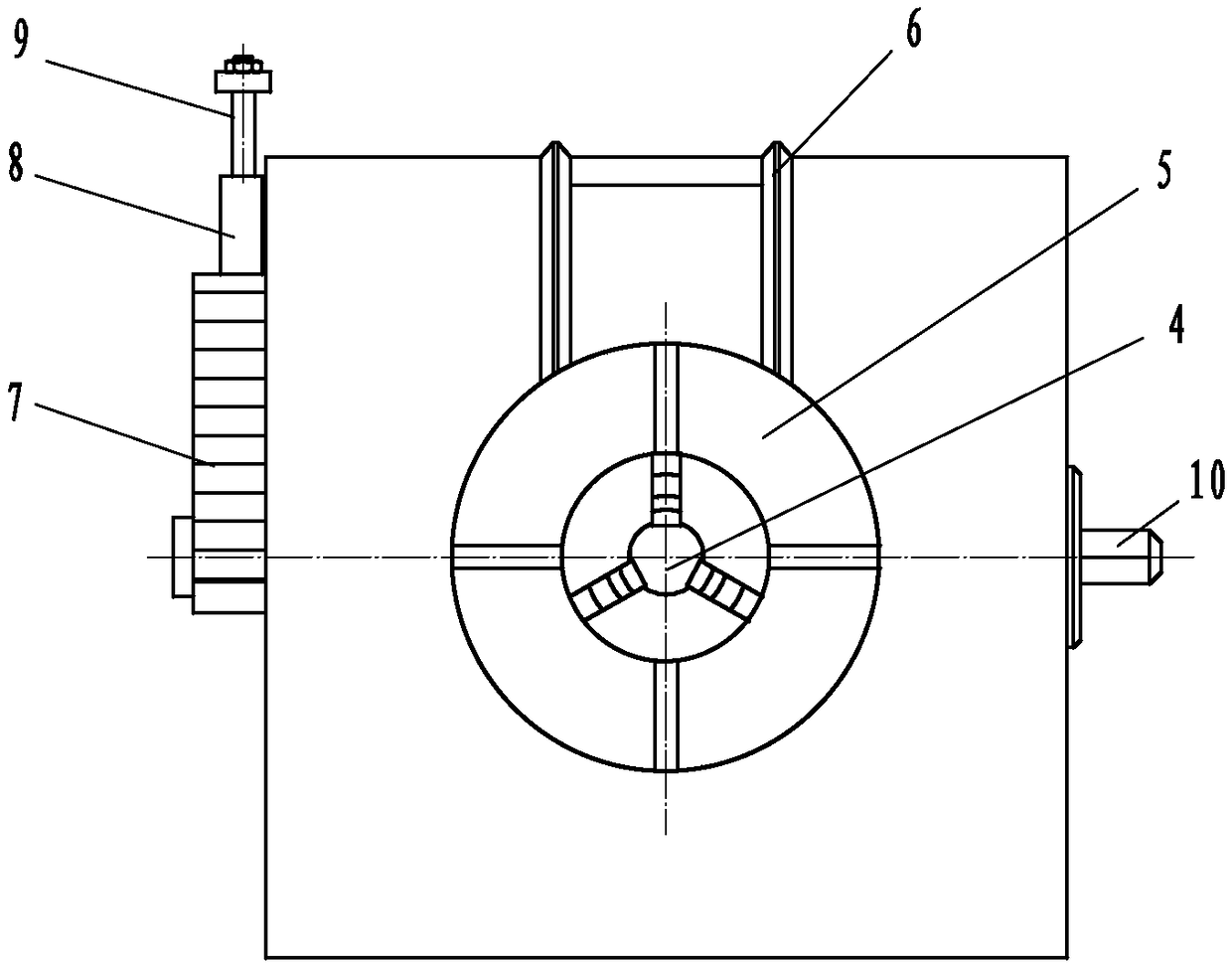

[0032] Embodiment 1: A four-axis rotary table with adjustable angle for a CNC milling machine, such as Figure 1-Figure 5 As shown, it includes outer casing 1, input shaft 10, helical gear 1 13, helical gear 2 14, inner ring sleeve 3, middle sleeve 15, outer sleeve 2, four-axis table 5, swing shaft 17, angle adjustment A central axis 18, an angle-fixed pull stud 9, a pull stud limit support 8 and a dial 7, the outer shell 1 is a cube whose upper right end is a transitional arc surface, and the arc surface of the outer shell has an angle adjustment channel 101, The edge of the angle adjustment hole is provided with a guide rail 6 , that is, the guide rail and the outer shell are connected with an elongated fixing screw 23 . The input shaft 10 is respectively mounted on the outer shell and the bearing seat 12 through bearings, and the two supporting points determine the horizontal position of the input shaft 10, and one end of the input shaft extends to the outside of the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com