Additive and equal material composite metal 3D laser forming device and method

A composite metal, laser forming technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of low density of parts or parts, unsatisfactory surface accuracy, low material utilization rate, etc. The effect of increased density, improved working environment, and improved material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

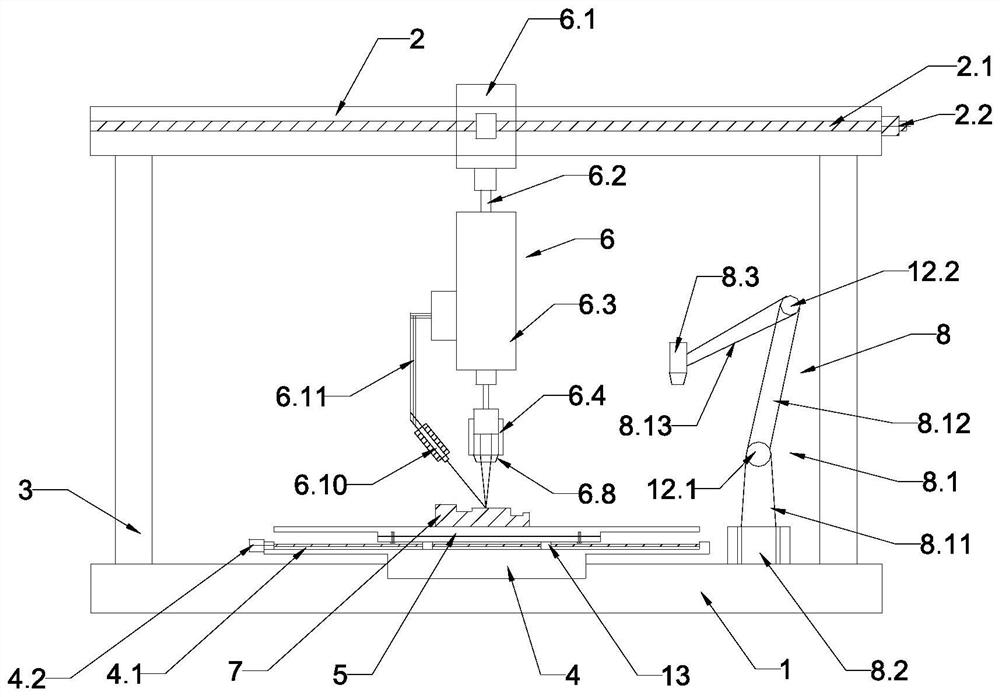

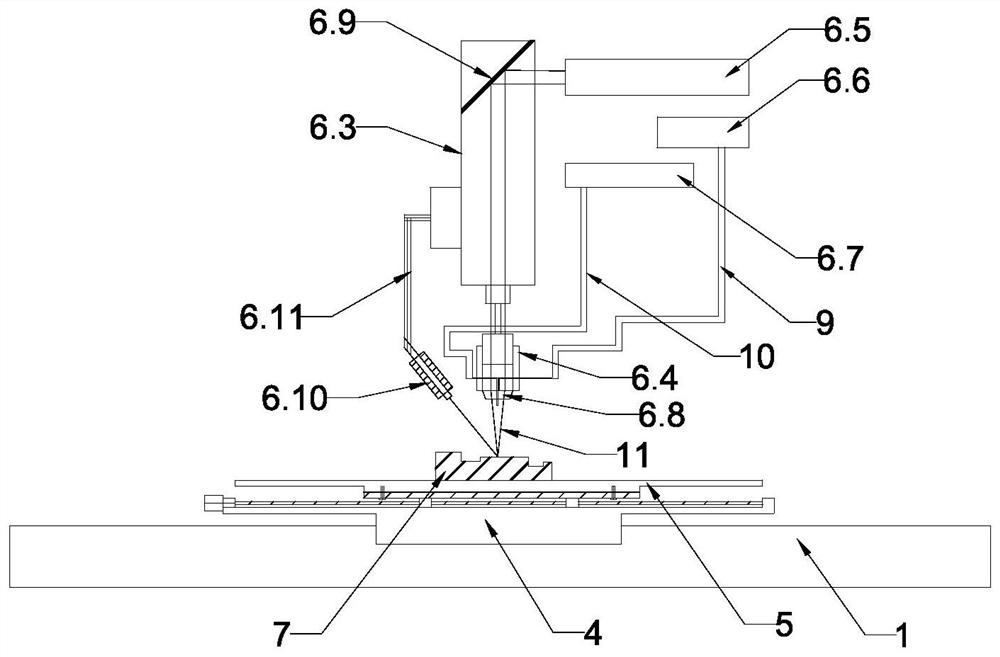

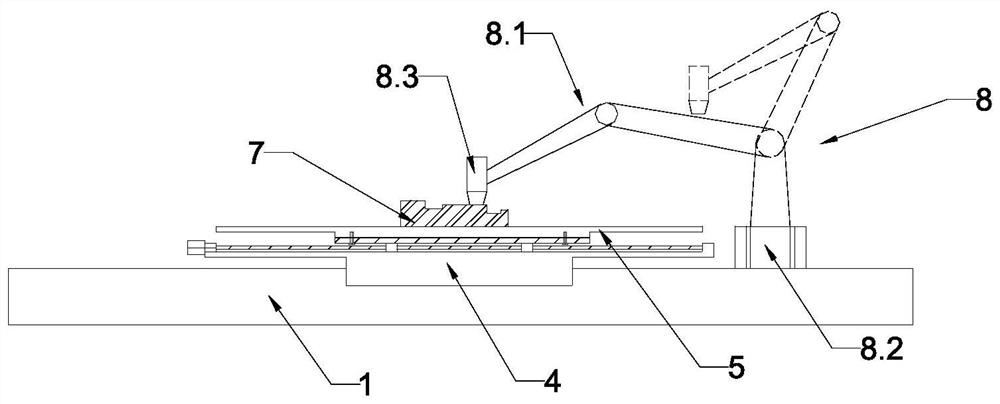

[0038] like figure 1 A 3D laser forming device for additive and equal-material composite metal shown includes a base 1 and a host beam 2. The host beam 2 and the base 1 are fixedly connected by columns 3 arranged on both sides. It also includes a base set on the base 1, a pan-tilt base 4 that can rotate relative to it, and a workbench 5 that can move laterally relative to it for placing a workpiece 7 is provided on the pan-tilt base 4, and a workbench 5 that can move up and down relative to the main beam 2 is arranged on the top of the workbench 5. A material processing mechanism 6 that moves laterally; a material processing mechanism 8 is provided on one side of the pan-tilt base 4 . The upper end face of the cloud platform base 4 is provided with the 3rd transmission screw mandrel 4.1, and one end of the 3rd transmission screw mandrel 4.1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com