Double-layer die changing system of door cover edge-wrapping press

A technology of press and hemming, applied in the field of double-layer mold change system, can solve the problems of prolonging mold change time, reducing production tact, affecting the efficiency of pressing parts, etc., to ensure stable movement, eliminate the danger of mold falling, and improve The effect of mold change efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

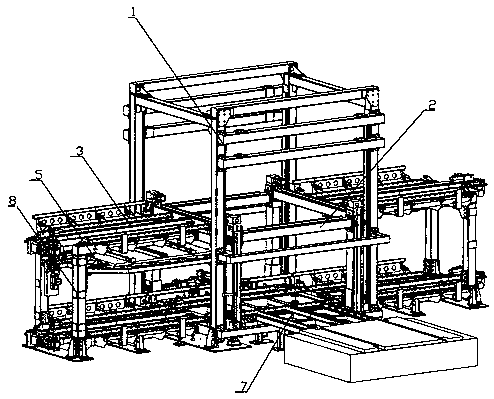

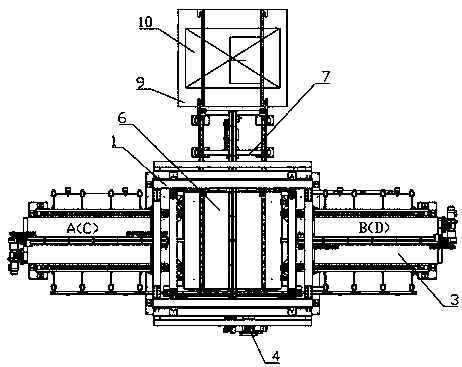

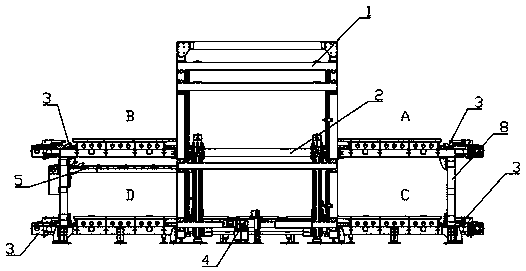

[0052] like Figure 1-11 As shown in the figure, a double-layer mold change system of a door cover hemming press includes a frame fixing device 1, an electrical control system and a hydraulic pump station, and the hydraulic pump station includes a pump station, a main valve unit, a synchronization unit and hydraulic pipelines, A mold lifting device 2 is installed inside the frame fixing device 1, and the mold lifting device 2 is connected with a hydraulic pump station. The frame fixing device 1 is connected with four mold storage devices 3, and the four mold storage devices 3 are respectively located The upper left, the lower left, the upper right and the lower right, the two mold storage devices 3 on the left are symmetrical to the two mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com