Lens film stripping equipment

A technology of film removal and equipment, which is applied in the direction of chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. It can solve the problems of inability to remove film color on the lens surface, limited level of film removal technology, and high cost of nitrate materials. , to achieve the effect of promoting reprocessing after stripping, reducing the number of scrapped products, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

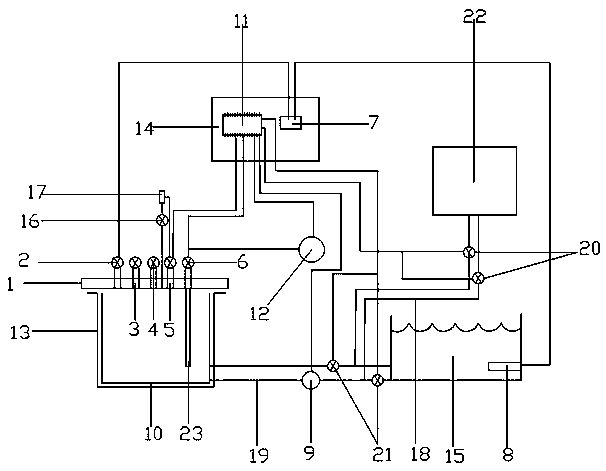

[0016] The present invention will be described in detail below through embodiments in conjunction with the accompanying drawings.

[0017] As shown in the figure, this embodiment provides a lens stripping equipment, a lens stripping equipment, including a reactor body 13, an electrical box 14 and a PLC 11, and a temperature sensing probe 2 is connected to the lid 1 of the reactor , Automatic pressure relief explosion-proof valve 3, pressure gauge 4, air release solenoid valve 5 and intake solenoid valve 6, wherein the reaction kettle is a simple reaction kettle that can quickly open the door.

[0018] The temperature sensing probe 2 is connected to a thermostat 7, and the thermostat 7 is connected to the heating pipe 8 inside the hot water tank 15 to form an automatic temperature control system that can be set. The thermostat 7 realizes automatic temperature control through PLC11. The kettle cover 1 is connected to the high-pressure air pump 12 through the air intake electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com